The Fascinating World of Plastics Extruders

Plastics extruders are amazing devices for the production of a heavy variety of plastic goods, just like the Faygo Union's product called blow film extrusion machine. In essence, they operate by melting down a granulated plastic material and extruding it in continuous ribbons, then heated up locally before shaping. This plastic profile extruders is quite reminiscent of 3D printers and most commonly used in the industry to produce a large number of tubes, pipes, film and sheet etc.

A plastics extruder is the machine that starts with a pallet of some type-for most machines it is in pellet or granule form, such as polyethylene pellets, identical to plastic pelletizing line manufactured by Faygo Union. The molten plastic material goes through a die which gives the desired shape and size. Faygo Union plastic pet bottle making machine come in two main types - The single screw and twin-screw plastic machines. While single screw extruders are good for simple jobs, the twin-screw has better performance potentials when processing higher viscosity materials or when incorporating fillers and additives.

One account of how extrusion technology was used to make custom packaging for different appliances, similar to the Faygo Union's product like sheet extruder. Manufacturers will use new technologies to fine-tune their processes and create any number of shapes/sizes for packaging. Sensors and controls can monitor the production on-line, such that custom plastic bottle making machine produce same high-quality performance from start to finish.

While plastics extrusion technology has its unique challenges, there is a greener tomorrow with new bio-based bio plastics taking the stage, also the 2 cavity pet blowing machine manufactured by Faygo Union. This technology has varied industrial applications, gaining ground in industries like construction, automotive as well packaging and also health. Everything from basic materials such as plastic tubes and sheets is produced to more complex Faygo Union plastic extrusion machine products (such as the artificial joints or prostheses used in medicine) has developed a variety of medical applications continues to plastics extrusion meet diverse business needs.

For plastics extrusion, efficiency relies on a number of factors; selecting the right resin and designing machines for specific processes are two big ones but setting up effective maintenance programs is just as important, as well as the Faygo Union's pet plast blowing machine. Faygo Union plastic extruder are expensive and cleaning extruders once per week keeps the process running smooth. Keeping abreast of global industry developments, and ensuring that sustainable operations are a priority is crucial if growth in the sector focusing on plastics extrusion.

Increased output(doubled) Rotary perform uploading Soft continuous, Plastics extruderscontinuous running, instead of step-by-step and movement that \more gentle. Reduce Bad Bottle Rate. Only equipped with two heating boxes, each one's heating head's distance is reduced to 38.1mm and can save 30% electric than the conventional model, which \about 130000 kwh of electric power. So, for a year that is based \eight hours per day, can reduce 20000USD only on heating power; More than 100+ countries have us as partners my company after service team.

FAYGO UNION GROUP now has over 500 customers different countries, including UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. Europe ,and America, Canada, Mexico, Brazil, Venezuela, Chilly etc from America as well as Saudi Arabia, Iran, Syria, India, Thailand, Plastics extrudersetc. from Asia a lot clients from Africa. Our factory situated Zhangjiagang city, which covers an area of 26,650 square metres. distance from airport to factory is just two hours.

Sales managers online 24 hours day provide the most rapid service. you have any questions about products or services, please contact . Patents and Certificates: Faygo Plast has 13 national patents. Among them are 8 invention patents. constantly improve our products to Plastics extruderslatest technologies to our customers. Our products have CE ISO certifications

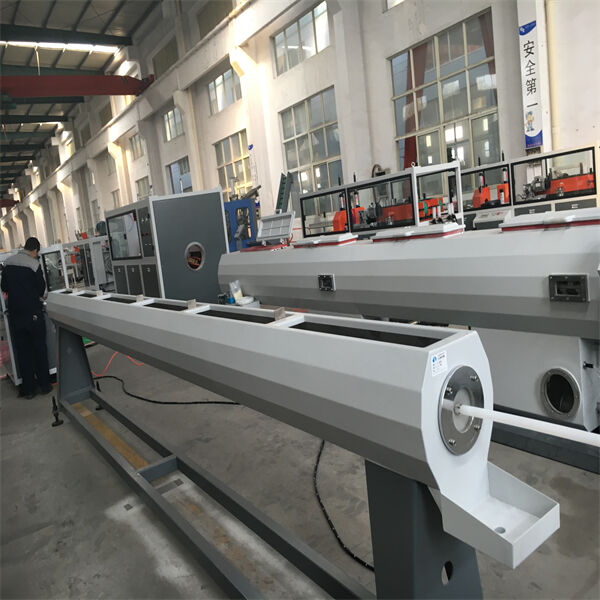

FAYGO UNION GROUP made up of 3 branches. FAYGOBLOW a blow molding machine manufacturer for PET, PE other materials. FAYGOBLOW has 5 patents covering inventions 8 patents for utility models. FAYGO PET blow moulder is the quickest and most effective design in the world. second manufacturing facility is Plastics extruderswhich produces extrusion machines made of plastic, such as extruding lines for plastic pipe, extruding lines made plastic profiles. Especially FAYGOPLAST can supply high-speed up 40 m/min PE PPR pipe line.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy