Machines For Making Plastic Bottles

Plastic bottles are utilized for many different daily needs including a vessel to hold your drink, or containing cleaning products. These machines are used to produce these bottles. These machines transform raw materials into durable, light bottles that people and companies rely on. Now more than ever, with an increased focus on going green, the production plants for plastic bottles are becoming a greater necessity. This article discusses how the next generation of these Feige Youlian Machinery plastic pet bottle making machine may appear, attributes to consider when purchasing one and what innovations are making them more eco-friendly, as well their operation and competitiveness for companies.

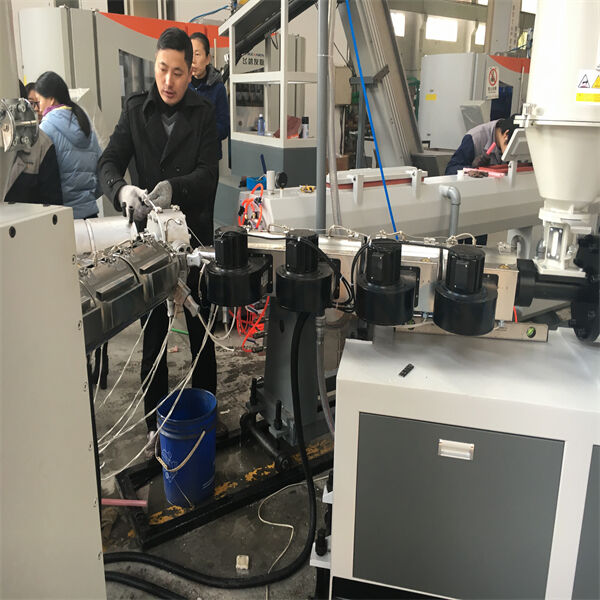

The days ahead for plastic bottle making machines are all about innovation, and going sustainable. The precision, perfection and the ultimate flexibility - all of this is grasped faster by Feige Youlian Machinery machines. The innovative concept will also help keep companies on track with what consumers want and enforces to limit the production of disposable bottles. In some cases, machines are also being developed to handle more environmentally friendly materials, such as bio plastics and recycled plastics. Furthermore, smart technology can make these plastic recycling washing line more efficient and require less energy to operate.

There are some things to consider while selecting a plastic bottle making machine.

Compatible with various materials: Select machines which are able to work in diversified-varied types of fields.

Energy saving - Look for Feige Youlian Machinery devices that consume less energy to save you money.

Final Production: Ensure the machine can make bottles that match your requirements.

Control: Reliability and precision for automating machine processes to forge better bottles.

Eco-Friendliness: Certain devices capable of recycling themselves, or using recycled supplies.

New plastic bottles are being created to be environmentally friendly. Systems like the one described below can, for instance recycled old plastics into new raw materials. Light weighting the bottles also contributes to saving on plastic as well. The Plastic Extrusion Machine are increasingly looking for biodegradable plastics produced from plants, and that too requires changes on the machines.

The plastic bottles manufactured goes through some steps;

Material Preparation: Melt materials in the form of substrates.

Extrusion and Blowing- Melted plastic is moulded into a tube and pumped up like a balloon.

Cooling and Finishing: The plastic cools off and then moves on out of the mold as a bottle.

Quality Control and Finishing: Inspect and label bottles Affix Closures Package

Understand the Process to Ensure a Quality Bottle

output has been increased (doubled) Rotary perform continuous running instead step-by-step, more smoothly. Reduce Bad Bottle Rate. Only equipped two heating box, each head's distance to heating source decreased to 38.1mm and can save 30% more electricity than plastic bottle making machineone, which is around 130000kwh power. That's entire year, based on 8 hours per day, could save you 20000USD only heating power. Over 100 countries select us to be their partners well as my own after service team.

Service online: sales managers are 24 hours online provide customers with fastest response. Please contact if you have any questions regarding our products. Patents Certificates: Faygo Plast has 13 national patents, which include eight invention patents. are constantly improving our plastic bottle making machineorder to provide most advanced technology to customers. Our product have CE and ISO certificate.

FAYGO UNION GROUP made from 3 plastic bottle making machine. FAYGOBLOW a blow molding machine manufacturer PET, PE other materials. FAYGOBLOW has 5 patents covering inventions, eight patents utility models. FAYGO PET blow molding machine among fastest and most energy-efficient design worldwide. second manufacturing facility is FAYGOPLAST, which make plastic extrusion equipment. This includes the plastic pipe extruding line and extruding line for plastic profile. Particularly, FAYGOPLAST is able provide PPR, PE pipes at speeds that can reach that can reach 40m/s.

FAYGO UNION GROUP now more than 500 customers spread across countries like UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. From Europe, America (Canada, Mexico, Brazil Venezuela, Chilly, etc.) and Saudi Arabia, Iran Syria, India, Thailand Indonesia Thailand Indonesia. Many customers coming from Africa as well as Asia. Our factory, which is located in Zhangjiagang City, has an area of 26650 square plastic bottle making machine. only takes around two hours driving to SHANGHAI International Airport.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy