packaging details: sea worthy packaging for the profile making machine

delivery detail: 45 days since receive the down payment

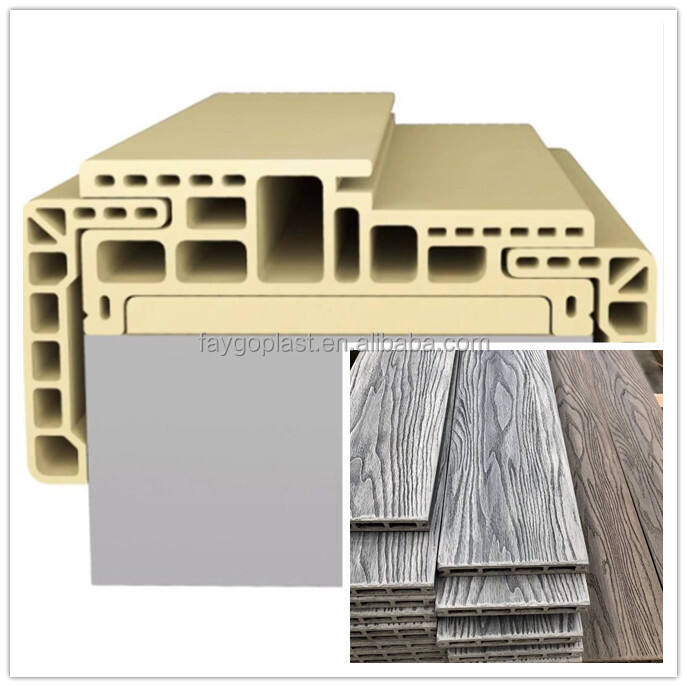

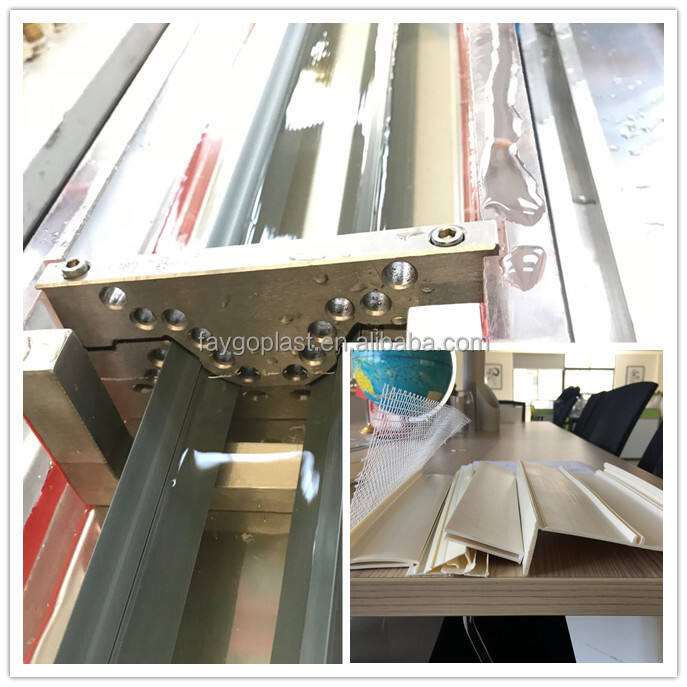

Faygo Union Machinery’s WPC door frame profile WPC decking profile extrusion line with laminating machine was built to be the ultimate answer for anyone that wants to put a sturdy and dependable WPC door frames and decking profile. Their WPC door frame profile and decking profile line with laminating machine is the perfect item for anyone who need to purchase top-quality, safe frames and decking panels.

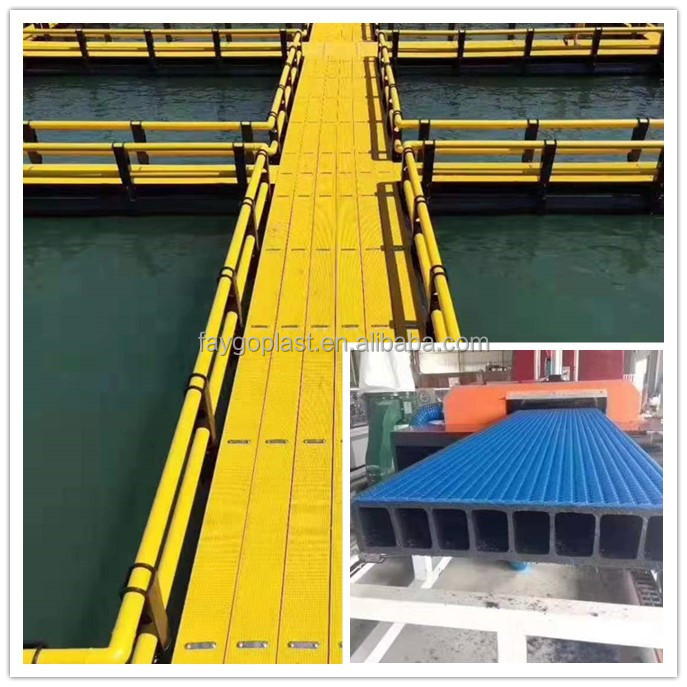

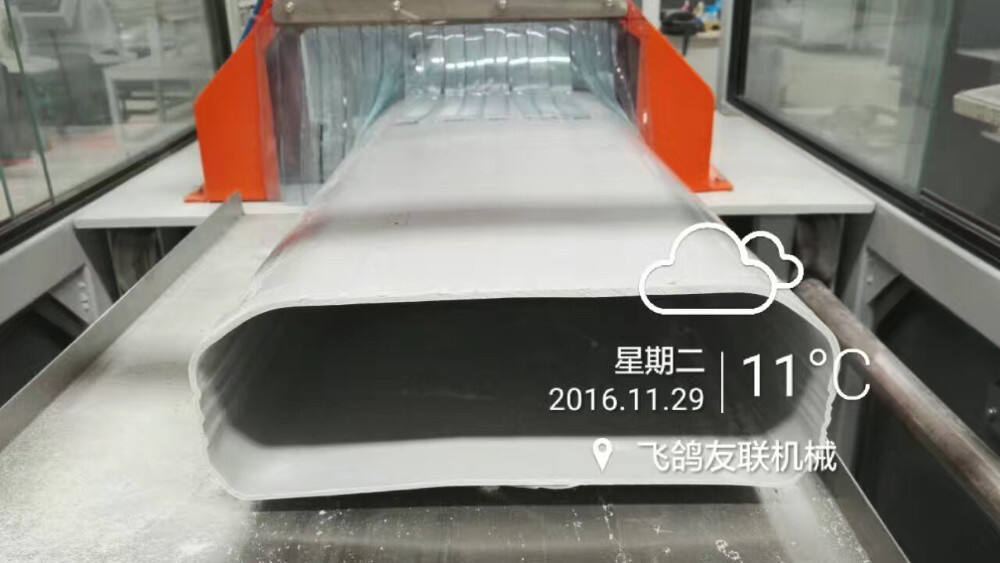

The extrusion line features cutting-edge technology, meaning that all profile are produced with the greatest quality. The profiles are manufactured to be durable, lasting, and effect resistant, while being effortless and lightweight to create. Created from a combination of lumber fibre and plastic, these profiles are strong and resilient, making them ideal for any outside area.

The laminating machine is another important function of this extrusion line. The machine was built to use a laminated film on the top of pages that serves as a protective barrier against scratches, spots, and other types of harm. This extra layer adds a supplementary protection to the profile, making sure it is going to stay in top condition for a long time.

Installation is simple and hassle-free, while the extrusion line was made to produce profiles of various sizes to complement any task or application. All profiles can be cut to fit, enabling an ideal fit every time.

The WPC door frame profile WPC decking profile extrusion line with laminating machine is the perfect item for any property owner or specialist who want to purchase top-quality items that will stand the test of times. All profiles produced by this extrusion line are eco-friendly, making them the right selection for those that wants to live green since they are produced from recycled materials

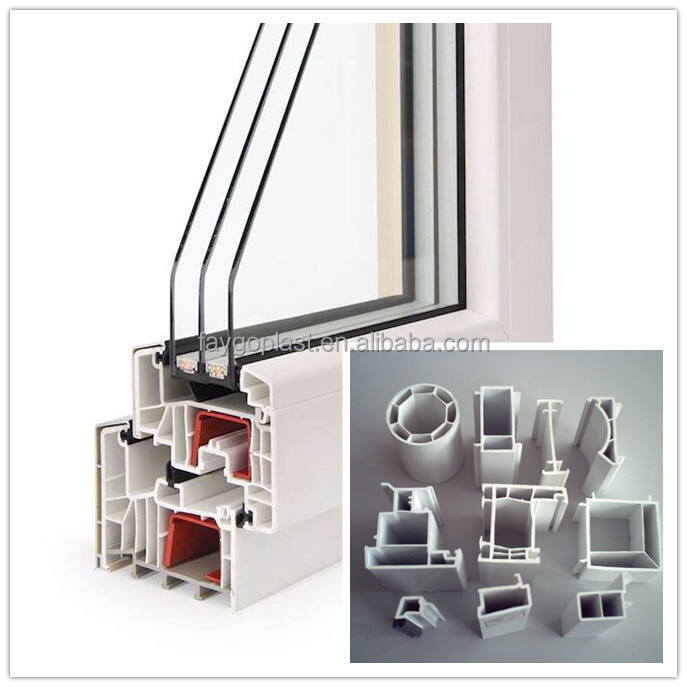

The PVC profile is mostly used in building & construction industry, for example door panel and frame, PVC ceiling, window frame, edge banding, building corner profile, etc

Application:

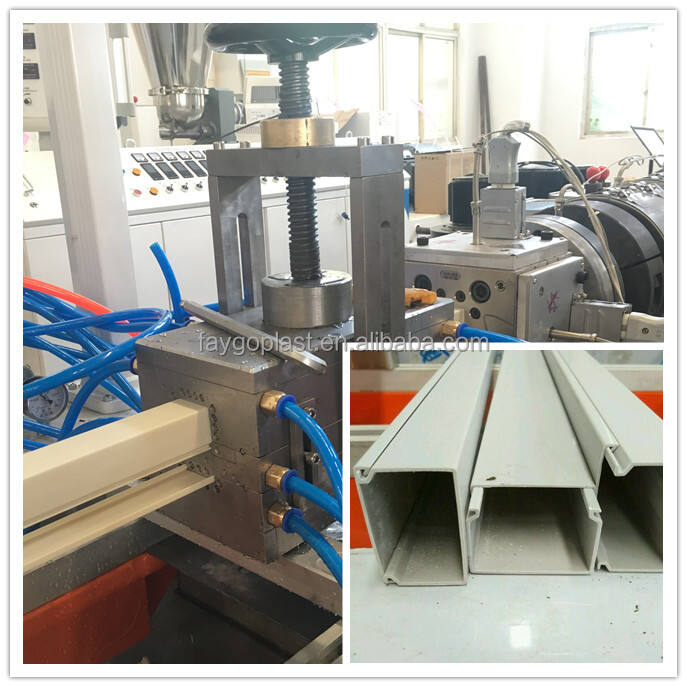

1. Particular designed conical twin screw for PVC powder raw materials

2. Adapted to different moulds for different PVC profiles

3. With special designed vacuum calibration platform, haul-off and cutter, stacker

4. Adopt with full aspects efficient water mist cooling on profile

Model | YF180 | YF240 | YF300 | YF600 |

Max product width(mm) | 180 | 240 | 300 | 600 |

Extruder model | SJ55 | SJ65 | SJZ65 | SJZ80 |

Extruder power | 22 | 30/37 | 37 | 55 |

Cooling water(m3/h) | 5 | 7 | 7 | 10 |

Gas consumption(m3/min) | 0.2 | 0.3 | 0.3 | 0.7 |

packaging details: sea worthy packaging for the profile making machine

delivery detail: 45 days since receive the down payment

FAYGO UNION GROUP has 3 branch factories. One is FAYGOBLOW which design and make blow molding machine for PET, PE etc. Second factory is FAYGOPLAST, which make plastic extrusion machinery, including plastic pipe extruding line, plastic profile extruding line. Especially FAYGOPLAST can supply high speed up to 40 m/min PE, PPR pipe line. Third factory is FAYGO RECYCLING, which research new technology in plastic extrusion, film recycling processing and pelletizing

Now FAYGO UNION GROUP has more than 500 customers from different countries, including UK, Spain, Germany, Norway, Switzerland, Italy, Turkey Russia etc. from Europe, and America, Canada, Mexico, Brazil, Venezuela, Chilly etc from America, and Saudi Arabia, India, Thailand, Indonesia etc. from Asia, and many customers from Africa

Our factory is located in Zhangjiagang city, covers an area of 26,650 square meters. It only takes around two hours driving from SHANGHAI international airport. Welcome to visit our factory, and hope to cooperate with you in the near future

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy