Faygo Union Machinery presents its innovation that is latest in the line of plastic extrusion machine - the PPR three layers pipe fiber making machine / PPR fiber pipe co-extrusion plastic machine. Designed to meet with the increasing need of top-quality PPR pipe fibre, this product is the perfect solution for plastic manufacturers who wants to improve their manufacturing capabilities and item quality.

Constructed with superior quality materials and cutting-edge technology, the PPR fibre pipeline co-extrusion plastic machine is a versatile and efficient system which can be adjusted to various manufacturing needs. It comes with a three-layered extrusion that creates PPR pipes with improved durability and strength. The equipment's co-extrusion technology enables the incorporation of materials with different materials, including copper, aluminum, and glass.

This was made to create pipes with diameters which range from 16mm to 160mm, with a maximum production of 15m/min. Its high-speed extrusion system can manage various kinds of recycleables, including PP-R, PP-B, and PP-H. The machine’s control system is user-friendly, ensuring effortless procedure and minimal upkeep needs.

Faygo Union Machinery is devoted to supplying the most effective quality to its consumers. Thus, the PPR fibre pipe co-extrusion plastic machine is crafted with accuracy engineering and was built to last. The machine was designed with top-notch materials, including stainless steel, ensuring lasting performance and minimal deterioration.

With the Faygo Union Machinery’s PPR fibre pipe co-extrusion plastic machine, manufacturers can create high-quality PPR fibre pipe with additional durability and strength. These pipes will provide exceptional resistance to temperature, corrosion, and substances, making them well suited for different applications, including hot and cold water, warming systems, and chemical transport

20-63mm PPR Double Pipe Extrusion Machine Line

Features of our machine PPR Pipe Making Machine:

Multi layers PPR HDPE PE pipe making line, we can supply 2 layer, 3 layer, 4 layer pipe co-extrusion line

Zhangjiagang city Faygo Machinery 20-63mm three layer PP-R +fiberglass silicon core pipe production line specially designed for PPR 4 layer water pipes, gas pipe, sewages pipes and electric cable protection pipes making

Pipe Diameter range: 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, Single Pipe Outlets

1 |

SJ65 Single screw extruder |

2set |

2 |

SJ25 Single screw extruder |

1set |

3 |

Mould | 1set |

4 |

Vacuum Calibration Tank |

1set |

5 |

Two caterpillars Hauling Machine – |

1set |

6 |

Pipe Cutting Machine |

1set |

7 |

Stacker |

1set |

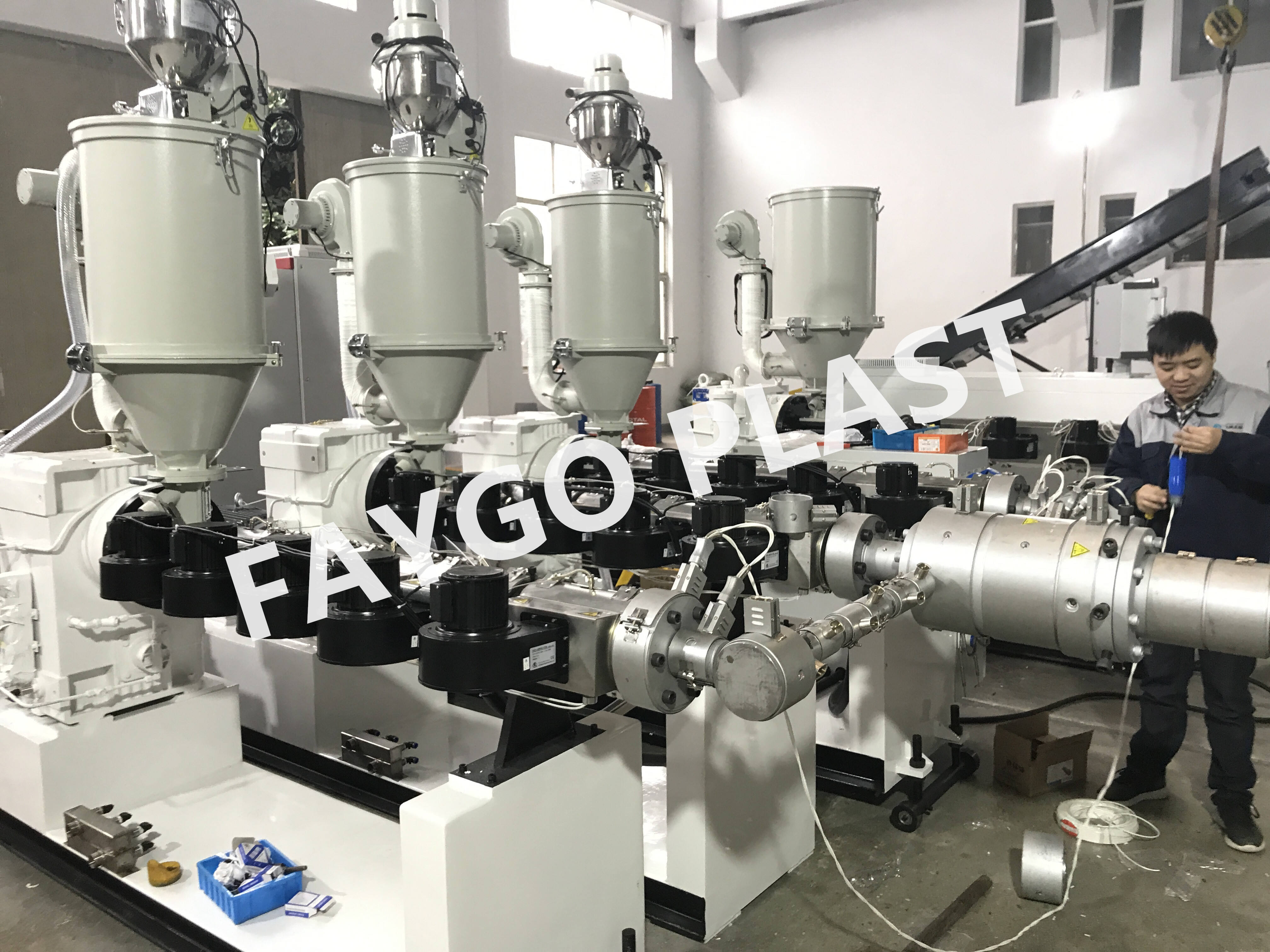

Machine Picture

1. The extruder and haul-off adopt imported AC frequency control device, vacuum pump and haul-off motors adopt high-quality brand

2. The haul-off methods are two-claw, three-claw, four-claw, six-claw, eight-claw etc

3. You may choose saw cutting type or planetary cutting type. It is additionally attached with the length counter and intensifying device

4. The equipment is with the reliable performance and high production efficiency

1. SJ 65 Single screw extruder machine:

![]()

Screw and Barrel: Design for PPR material, Screw and Barrel Material 38CrMoAlA, Nitriding, Surface Chrome plate, Nitriding Layer Thickness:0.5~0.7mm, Surface Rigidity:800~900HV.

2. Pipe Mold

Extrusion mold material: 40Cr. Calibration mold material: Wearable tin bronze ZQSn5-2-5

3. Vacuum calibration tank

Calibration Tank Length: 6m, Adopt 3mm thickness stainless steel board, Adopt 0.75KW Gearbox Speed Reducer Motor, Adjusting Distance equal to 800mm

4. Haul off and cutting machine

Haul-off Bracket Length 1200mm, Adopt Pneumatic gas cylinder,

Adopt 1.5kw*2sets ABB Inverter, Belt 80mm*2500mm

5. Stacker

Stacker length 4m, 1.5mm stainless steel board,

Stacking by Gas cylinder, Adopt limited switch send out cutting signal

Packing by film or wooden cases

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy