The Faygo Union’s PP PE PVC pipe making machine price/Plastic flexible pipe extruder production line is a top-notch manufacturing device that permits you to create versatile plastic pipes quickly and effectively. The device was made to meet the requirements of various applications, including water distribution systems, drainage systems, and fuel transportation systems.

The manufacturing line consists of few modules that are simple to run. The modules are made to raise the effectiveness to the manufacturing line, letting you create top-notch and versatile pipes with minimal waste. The product was also built to manage several types of PVC, PE, and PP materials to make pipes of several sizes, forms, and thicknesses.

One of the main attributes of the Faygo Union’s PP PE PVC pipe making machine is its cost-effectiveness. The unit is fairly priced, making it a good investment that is perfect for both small and large-scale companies. Furthermore, the product has low maintenance, helping you to save well on upkeep and expenses.

The manufacturing line was made with top-notch materials, making it durable and sturdy. The machine can withstand harsh working environment and make pipes that are produce meet the worldwide quality requirements. This machine is normally very easy to clean and maintain that makes it a good investment for companies that require machines with just minimal downtime.

The Faygo Union’s PP PE PVC pipe making machine was created with security in mind. The product has couple of safety features, including security switches, crisis end buttons, and guards, to prevent accidents at work. This was created to reduce sound amounts, making sure you can work in a safe, comfortable, and peaceful environment

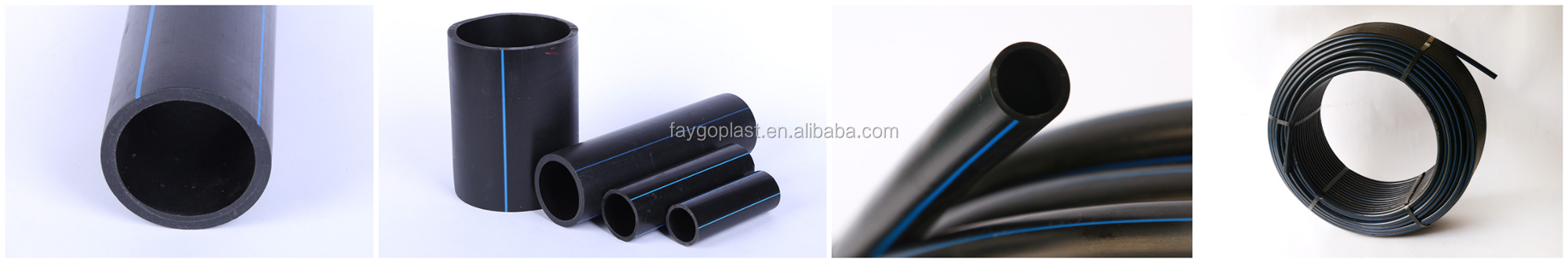

20-63mm PE Pipe Extrusion Machine Line

Features of our machine PE Pipe Making Machine:

PE electric conduit pipe making line, we can also supply 2 layer, 3 layer, 4 layer pipe co-extrusion line

Pipe Diameter range: 20mm, 25mm, 32mm, 40mm, 50mm, 63mm, Single Pipe Outlets

1 |

SJ65 Single screw extruder |

2set |

2 |

Mould | 1set |

3 |

Vacuum Calibration Tank |

1set |

4 |

Two caterpillars Hauling Machine – |

1set |

5 |

Pipe Cutting Machine |

1set |

6 |

Stacker |

1set |

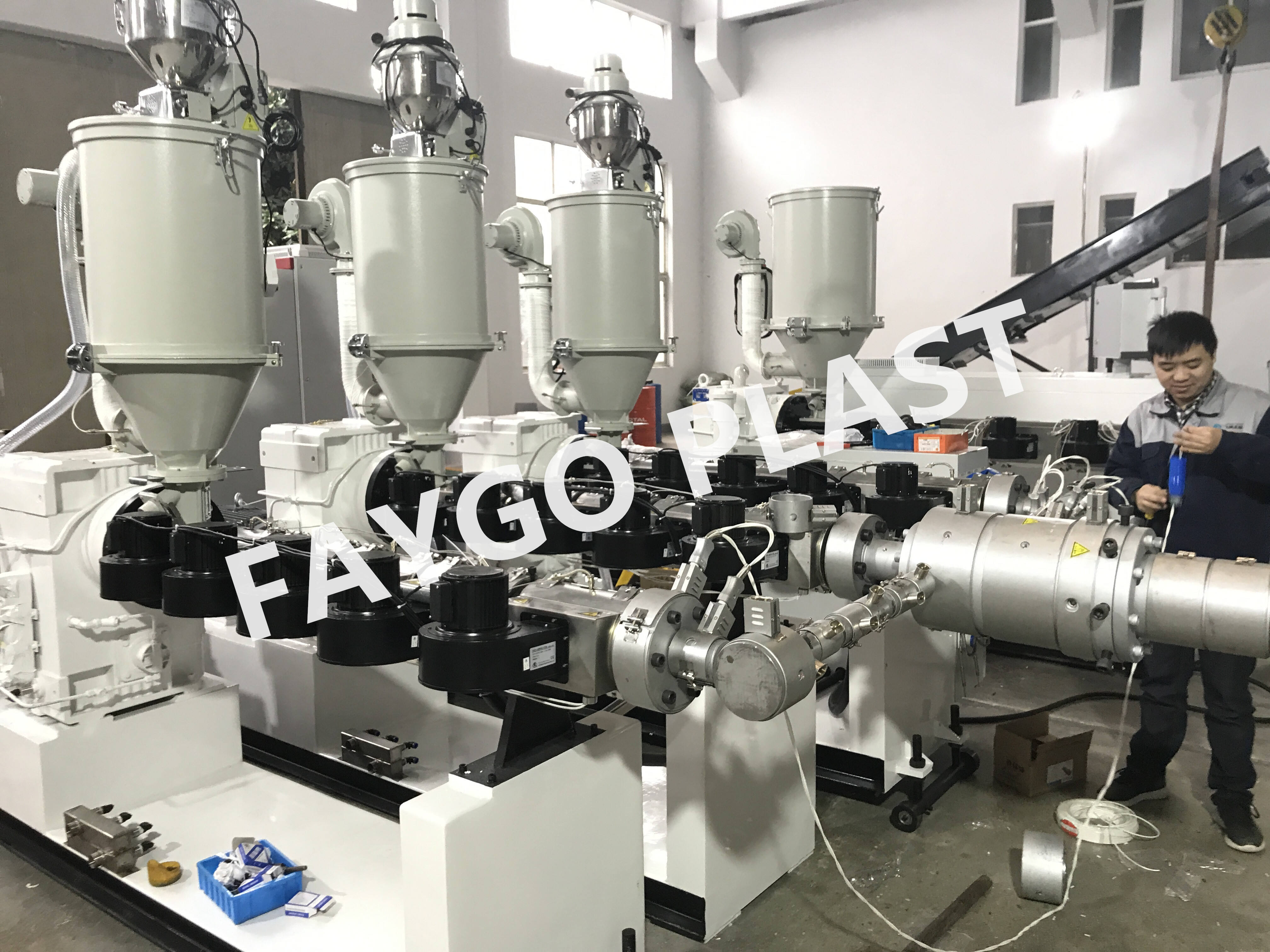

Machine Picture

1. The extruder and haul-off adopt imported AC frequency control device, vacuum pump and haul-off motors adopt high-quality brand

2. The haul-off methods are two-claw, three-claw, four-claw, six-claw, eight-claw etc

3. You may choose saw cutting type or planetary cutting type. It is additionally attached with the length counter and intensifying device

4. The equipment is with the reliable performance and high production efficiency

1. SJ 65 Single screw extruder machine:

![]()

Screw and Barrel: Design for PPR material, Screw and Barrel Material 38CrMoAlA, Nitriding, Surface Chrome plate, Nitriding Layer Thickness:0.5~0.7mm, Surface Rigidity:800~900HV

2. Pipe Mold

Extrusion mold material: 40Cr. Calibration mold material: Wearable tin bronze ZQSn5-2-5

3. Vacuum calibration tank

Calibration Tank Length: 6m, Adopt 3mm thickness stainless steel board, Adopt 0.75KW Gearbox Speed Reducer Motor, Adjusting Distance equal to 800mm

4. Haul off and cutting machine

Haul-off Bracket Length 1200mm, Adopt Pneumatic gas cylinder

Adopt 1.5kw*2sets ABB Inverter, Belt 80mm*2500mm

5. Stacker

Stacker length 4m, 1.5mm stainless steel board

Stacking by Gas cylinder, Adopt limited switch send out cutting signal

Packing by film or wooden cases

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy