Faygo Union's polycarbonate sheet production line SJ1200 is a top-of-the-line equipment that creates top-notch polycarbonate. This device was made with the latest technology and it was manufactured to meet the greatest criteria on the market. The SJ120 is effective at creating polycarbonate sheets in varying thicknesses, densities, sizes, and colors tailored to meet your particular needs.

The top-notch manufacturing procedure is blended with accuracy to make sure the final production is of the best quality. The manufacturing line is totally automatic. The SJ120 line employs an effective engine that executes effectively and efficiently, making certain the manufacturing rate is high, while the quality of the item isn't compromised.

The polycarbonate produced using this device is sturdy, durable, and can withstand many climate conditions. The SJ120 line comprises of machinery that produces polycarbonate sheets that are UV resistant, flame retardant, and effect resistant, making them well suited for used in different applications such as skylights, carports, greenhouses, arena roofs, children's pool covers, and much more.

The SJ120 line was built with state-of-the-art equipment that works for various functions such as cutting, trimming, and shaping to make sure that the last item is ideal. The line additionally includes a user-friendly control that allows for effortless track of the manufacturing procedure. Also, the SJ120 line is simple to keep up, with reduced functional expenses that make it a good investment for organizations that are seeking to attenuate costs while making the most of earnings.

Faygo Union's Polycarbonate Sheet Production Line SJ120 was created to focus on the requirements of various companies, including small, medium, and large-scale organizations that are looking to create top-notch polycarbonate to their clients. The SJ120 line has an efficient and dependable production with a manufacturing rate of the way to 600kg/hour, which makes it a perfect option for organizations that need high manufacturing rates

polycarbonate sheet production line SJZ51

We have three board / sheet extrusion line:

1. Hollow profile board extrusion line

2. sheet / board extrusion line

3. single and multi-layer sheet extrusion line

Technological process:

Plastic sheet extrusion machine -----Extrusion line-----Calibration unit-----Haul off unit-----Cutter-----Laminating machine etc.

1. Hollow profile board extrusion line

Main materials:PP, PC, PE

| Extruder Model | SJ123/38, SJ45/30 | SJ120/30 | SJ100/38, SJ45/30 | SJ100/33 |

| Raw material | PC | PP/PE | PC | PP/PE |

| Products thickness(mm) | 3-30 | 2-15 | 2-10 | 2-8 |

| Products width(mm) | 2100 | 2300 | 1300 | 1300 |

| Capacity(KG/H) | 450 | 400 | 300 | 200 |

| Motor Power(KW) | 200/18.5 | 132 | 132/18.5 | 110 |

Machine picture:

Hollow profile board extrusion line can make board like these:

2. sheet / board extrusion line

Main materials:ABS, HIPS, PMMA, PP, PE, PVC

| Extruder model | SJ120/35 | SJ150/35 | SJ170/35 | SJZ80/156 |

| Raw material | PP, PE, ABS | PP, PE, ABS | PP, PE, ABS | PVC |

| Products thickness(mm) | 3~30 | 3~30 | 3~30 | 3~30 |

| Products width(mm) | 1220 | 1500 | 2000 | 1200 |

| Capacity(KG/H) | 350 | 500 | 700 | 400 |

Machine picture:

sheet / board extrusion line can make board like these:

3. single and multi-layer sheet extrusion

Main materials:PET, PP, HIPS, PE, EVA

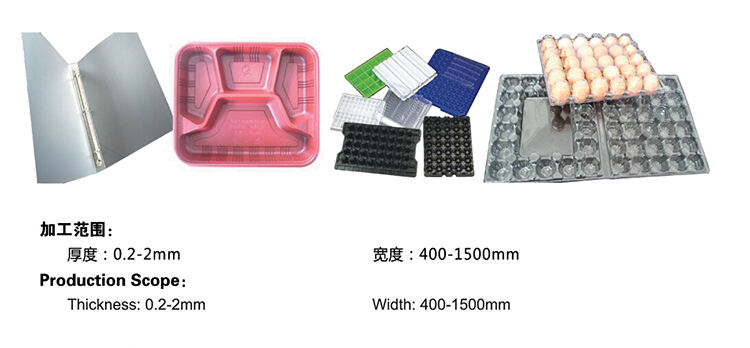

Production Scope:

Thickness:0.2-2mm Width:400-1500mm

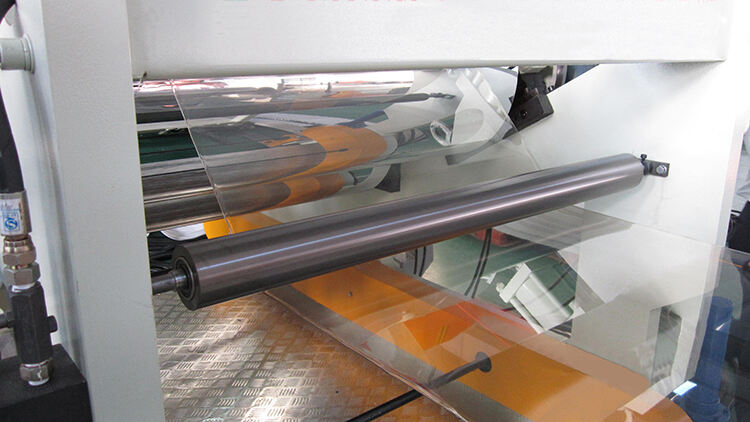

Machine picture:

3. single and multi-layer sheet extrusion lin can make can make sheet like these:

Our customer& electric brand below for plastic sheet making machine:

polycarbonate sheet production line SJZ51

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy