Faygo Union Machinery is proud to introduce the best quality solution for all your acrylic plastic sheet board needs – the High quality acrylic plastic sheet board making machine. This product is fantastic for companies that want a reliable and easy-to-use unit in manufacturing top-quality acrylic sheets. Faygo will provide you with you with the greatest quality products or services, whether you're a skilled maker or a novice.

This was engineered to be easy to perform, permitting you to begin creating high-quality acrylic that is straight away. It was built with an intuitive, user-friendly interface that provides all you need to start production immediately. With only a few clicks, the machine can start producing your item. This makes it a perfect solution for smaller businesses which have restricted resources and have to begin quickly.

The machine was manufactured out of durable and top-notch materials which ensure its long life and very good gratification. The sheet board was designed with high level technology, which means the item it creates is of the best quality. It was also made to be an easy task to keep, requiring minimal maintenance s and keeping your manufacturing line operating at maximum effectiveness.

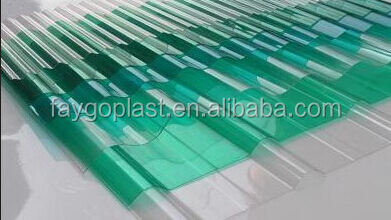

This comes in a compact and lightweight design that means it is an easy task to transport and keep without dealing with too much area. This benefit is essential for smaller businesses with restricted workplace. The product is extremely versatile, which allows you to develop a number of acrylic sheets, including transparent acrylic, colored acrylic sheets, and textured acrylic sheets, and other styles.

Another excellent function of this is its safety precautions. The machine was created to add interlock security that guarantee the security of staff, prevent any injury, and keep pace with the quality of the item. This machine will allow you to work efficiently, without worrying about staff security

acrylic sheet making machine

I. Application & Feature- acrylic sheet making machine :

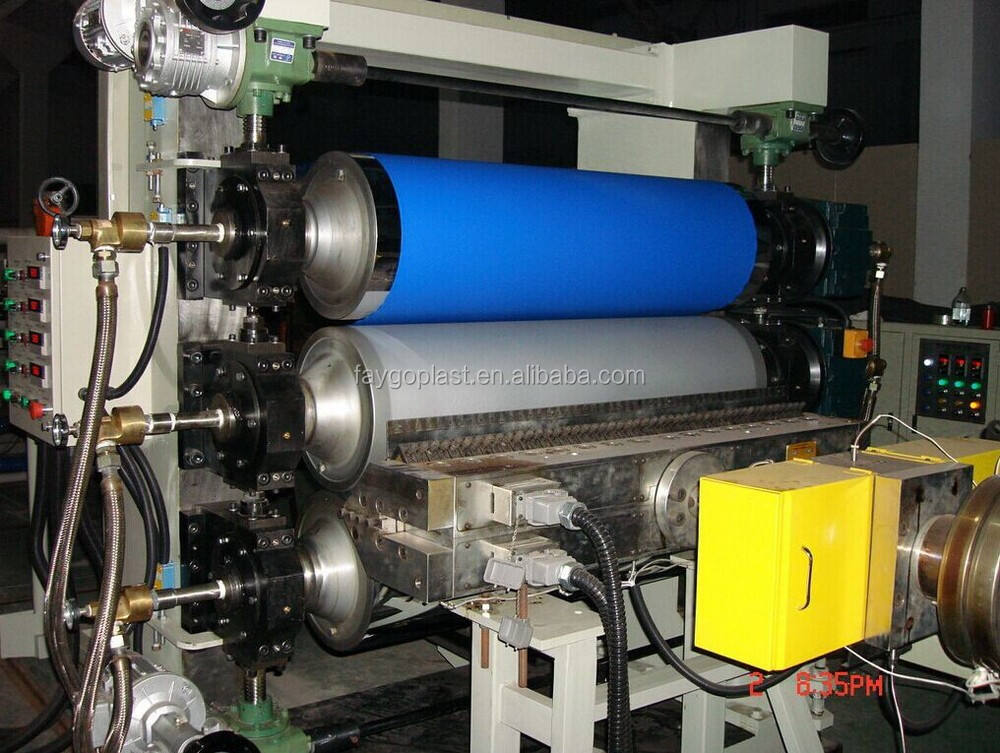

Plastic sheet/board extrusion line usually composed of extruders, screen changes, melt pumps, distributor, T-die, 3-roll calendar, cooling frame, haul-off unit, cutting of machine/winder and relative auxiliary machines, the raw materials are PET, PP, PE, PS, PC, EVA, PVC etc. final products thickness range is 0.2-30mm, width is up to 3 meters, the sheet /board are mainly used for package of food&industry stationary, electronic and so on industry

Main material are PP and PE, compared with paperboard, wooden board & aluminium board etc. The PP/PE board has much more advantages, it also can be substitute on many fields, like producing containers, mechanical cushion, kinds of bulkhead, poster board, packing case etc

2. Machines pictures:

3. Main Technical Parameter:

Extruder Model |

SJ120/38, SJ45/30 |

SJ120/30 |

SJ100/38, SJ45/30 |

SJ100/33 |

Raw Material |

PC |

PP/PE |

PC |

PP/PE |

Products thickness (mm) |

3-30 |

2-15 |

2-10 |

2-8 |

Products Width (mm) |

2100 |

2300 |

1300 |

1300 |

Capacity (KG/H) |

450 |

400 |

300 |

200 |

Motor Power (KW) |

200,18.5 |

132 |

132,18.5 |

110 |

4. Feature of equipment - acrylic sheet making machine

1) Our acrylic sheet making machine has High capacity

2) Energy saving: 20% energy saving than normal machines

3) Four self-designed major core technology of sheet extruder: extrusion system, die, roller, distributor. They are all invented and designed by ourselves. The core technology has many testing points and adopts electrical integration of double protection

4) The operation fully reflects the man-machine engineering principle, it can make the function more entirely and the operation more simple

5) Only the tablet machine independently walking, avoid the interference from other power to influence the stability of the sheet

6) The plasticizing effect of the sheet is very good. After the sheet formed and walking in curved line, it can make sure the stability of the sheet stock

7) The heating system is controlled by high-grade china heater, stainless heater, inner-storing type single heating pipe and precision temperature-controlling die mould, is exact in controlling temperature, quickly in heating, good in keeping temperature, long life and save time and energy

8) Our acrylic sheet making machine extrusion system adopt Japan Sanken frequency conversion motor with close loop which has the quick reaction, large torque, anti-interference and accurate feedback signal. The stability reaches the international standards

9) The pressure sensor adopts US Dynisco which has the feature that accurate feedback about the pressure, anti-interference and high precision

10) The fixed way of the mainframe device transform from concrete base to steel structure base. It is easy to install and can shorten the installing time and ameliorating the localization of unmovable

5. Application:

acrylic sheet making machine

- acrylic sheet making machine

After sales service

1> Find our products through our website: www.faygo.cn, and Alibaba, GlobalMarket, Made in China, Global sources, Traderkey

2> One year warranty for the whole system

3> We can send our engineers/technicians for installation of entire production line. Should make sure the safety of our engineers

4> After one year, we can help you to maintain the machine and the accessories are provided only one the cost price

5> Every 3 year, we can help to overhaul the machine freely labor

6> Free production technology and process configuration

7> We can help you to design the product line, workshop and provide turn-key project

- acrylic sheet making machine

FAQ:

Q: Your company is a transactional company or an industrial manufacture factory

A: We are an industrial manufacture factory which locates in Zhangjiagang city

Q:All of your products are made by your self or compacted via purchasing the others

A: We have independent technical team who focus on making machines, all the products are made by our technical team

Q:What is the ability of your factory

A:About 80 lines per year

Q:Do you have any other services about your products

A:We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system

Q:How do you make the quotation for clients

A:The price depends on quality and performance but the clients should be satisfied first

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy