Faygo Union

Automatic Plastic Bottle Water Drinks Filling Machine And Blowing Production Line would be the solution that is businesses that could be absolutely are perfect to improve their manufacturing procedures. Faygo Union is certainly a brandname title this is provides that are top-notch products to generally meet in what is required of organizations world wide. This technique features higher level technology, high production ability, and satisfaction that is really superior.

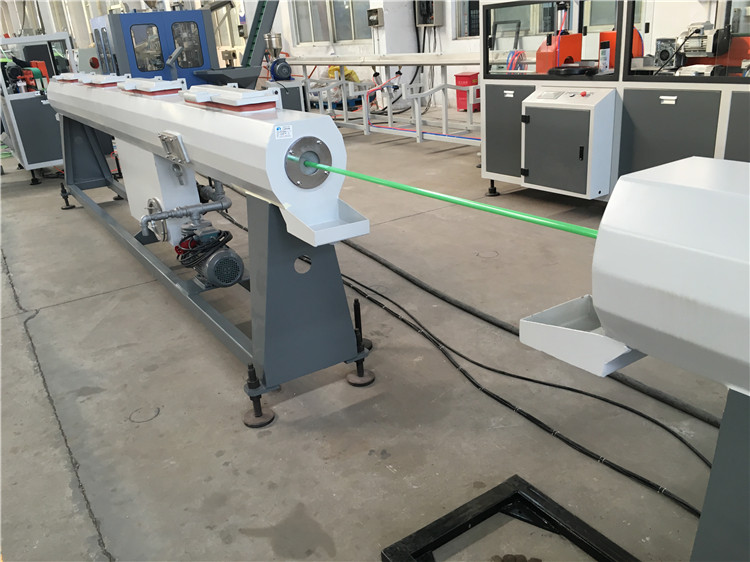

The Faygo Union Automatic Plastic Bottle Water Drinks Filling Machine And Blowing Production Line was created to fill up containers that are synthetic water products and services for the scale this is big. This method carries a stuffing this is the most of as much as 24000 containers each full hour, causeing this to be a selection businesses which are great wish to boost their production capability. The unit generally quite simple to work with, requiring intervention minimal is individual.

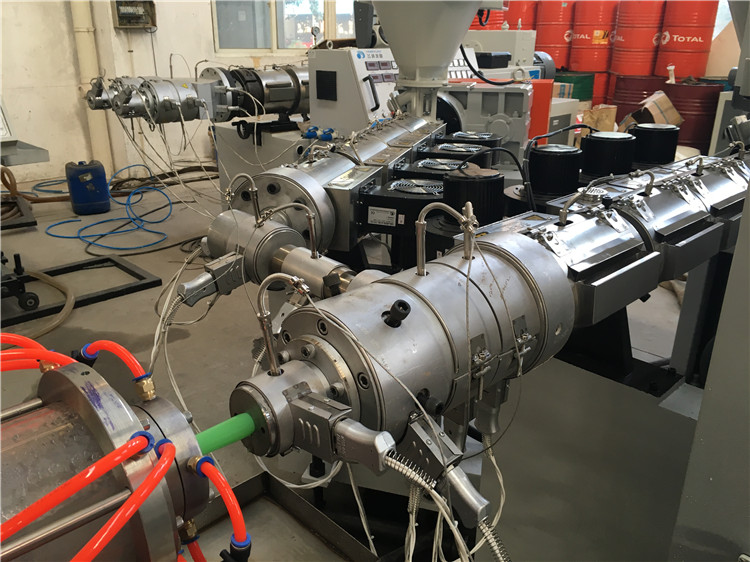

The production line features advanced technology that insures that water beverages are filled up effortlessly and accurately. It is really automatic, businesses will make certain that the unit operates effortlessly, decreasing the chances of downtime combined with the control. This production line was made to save lots of companies time and money while increasing production effectiveness.

Additionally, the Faygo Union Automatic Plastic Bottle Water Drinks Filling Machine And Blowing Production Line includes a production this really is really blowing this really is really made to make containers and that can be synthetic. This feature that is particular is specific that organizations do not need to purchase products which are various make bottles that are artificial which saves them money. Additionally, the containers which can be artificial as a result of gear are of quality and sturdy.

In relation to upkeep, the Faygo Union Automatic Plastic Bottle Water Drinks Filling Machine And Blowing Production Line was made to lessen downtime. The apparatus is easy to keep that will be designed to provide performance this is lasting. This system can endure for a time that is long value that is including organizations with appropriate maintenance.

Model |

SJ45/28 |

SJ65/28 |

Pipe diameter scope(mm) |

8-32 |

16-50 |

Max. diameter(rpm) |

45 |

65 |

L/D |

28: 1 |

28: 1 |

Screw rotate speed |

600 |

500 |

Moter power(kw) |

11 |

18.5 |

braider moter power(kw) |

2.2 |

3 |

Output(kg/h) |

40-60 |

60-120 |

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy