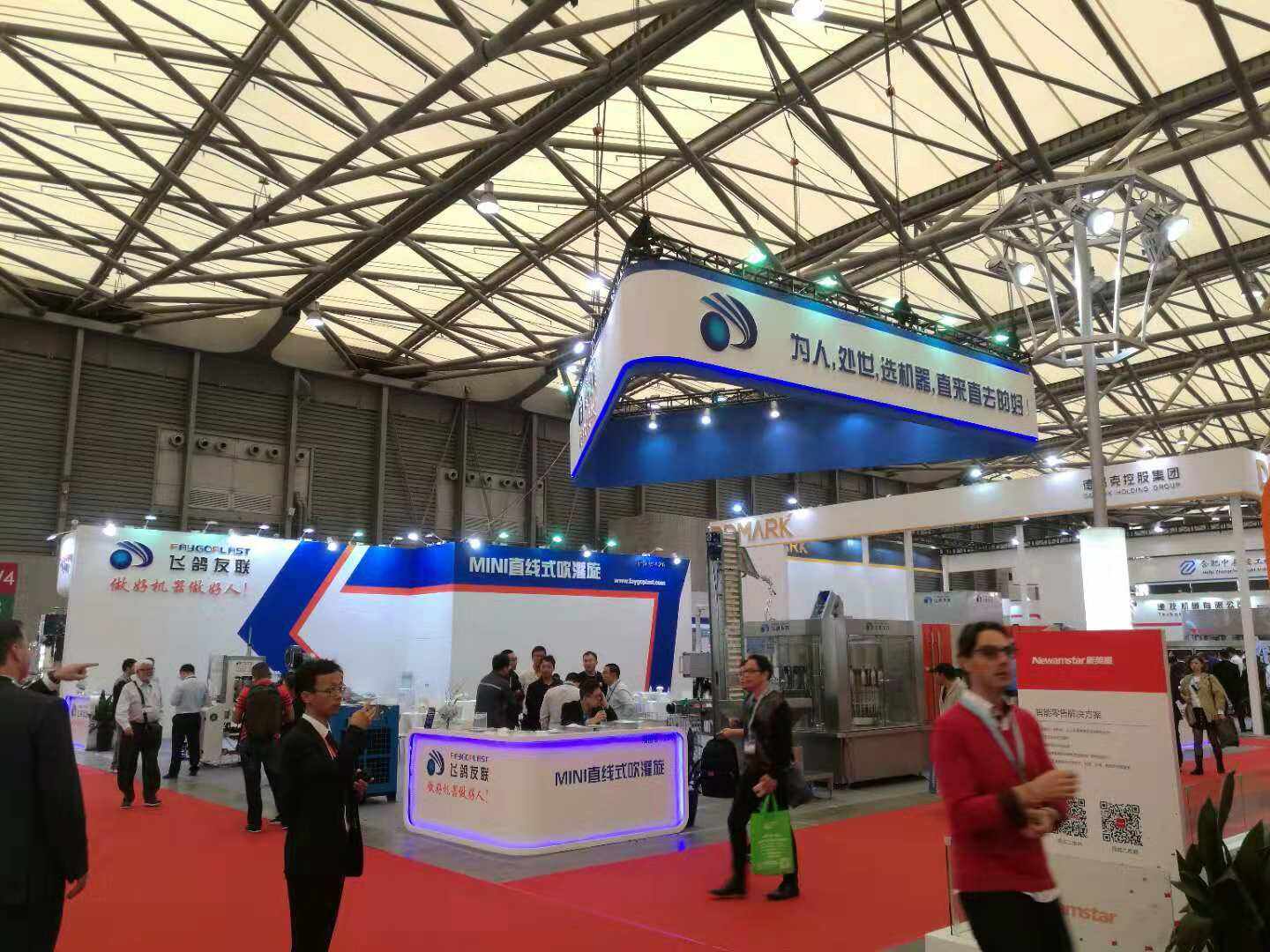

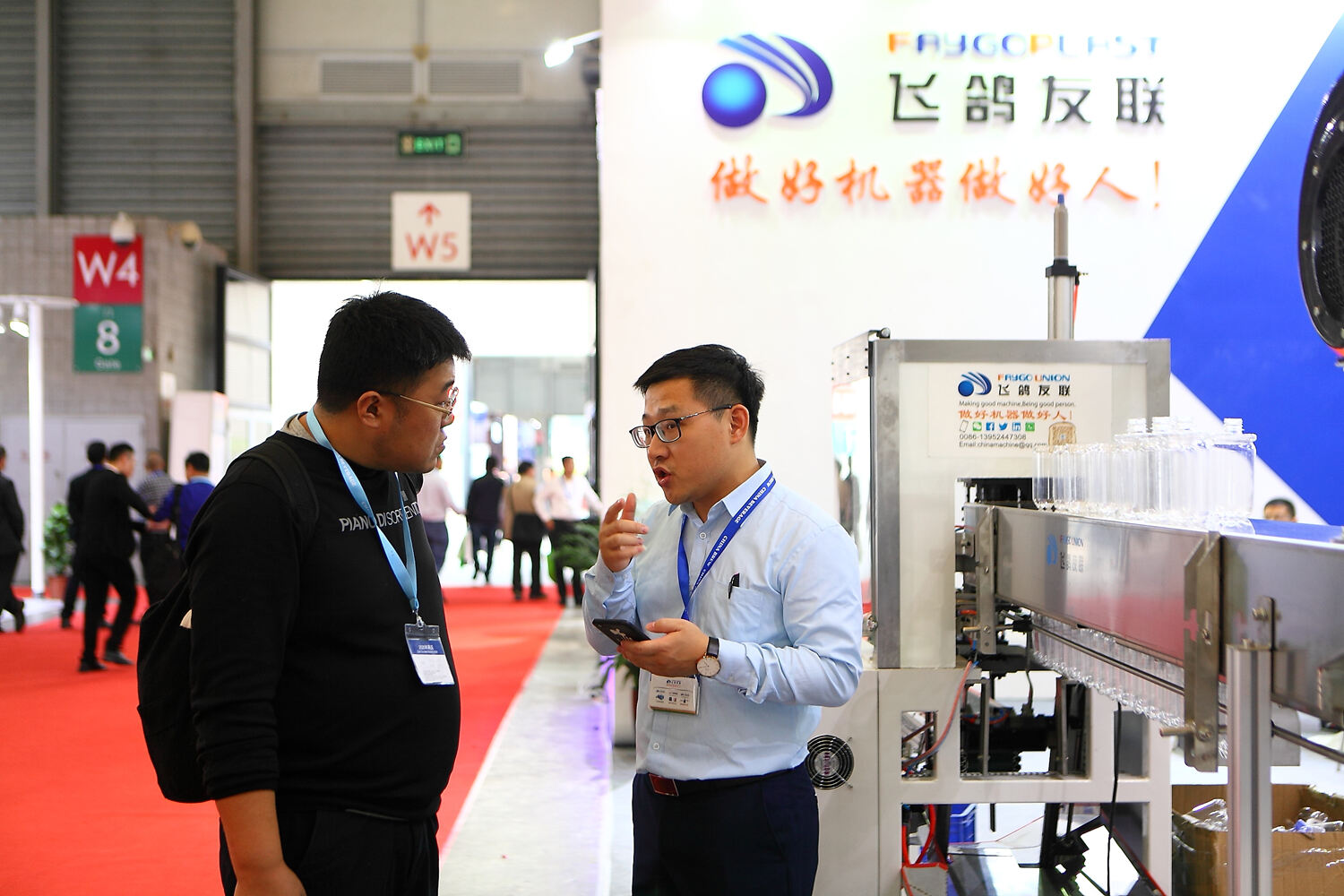

Faygo Union

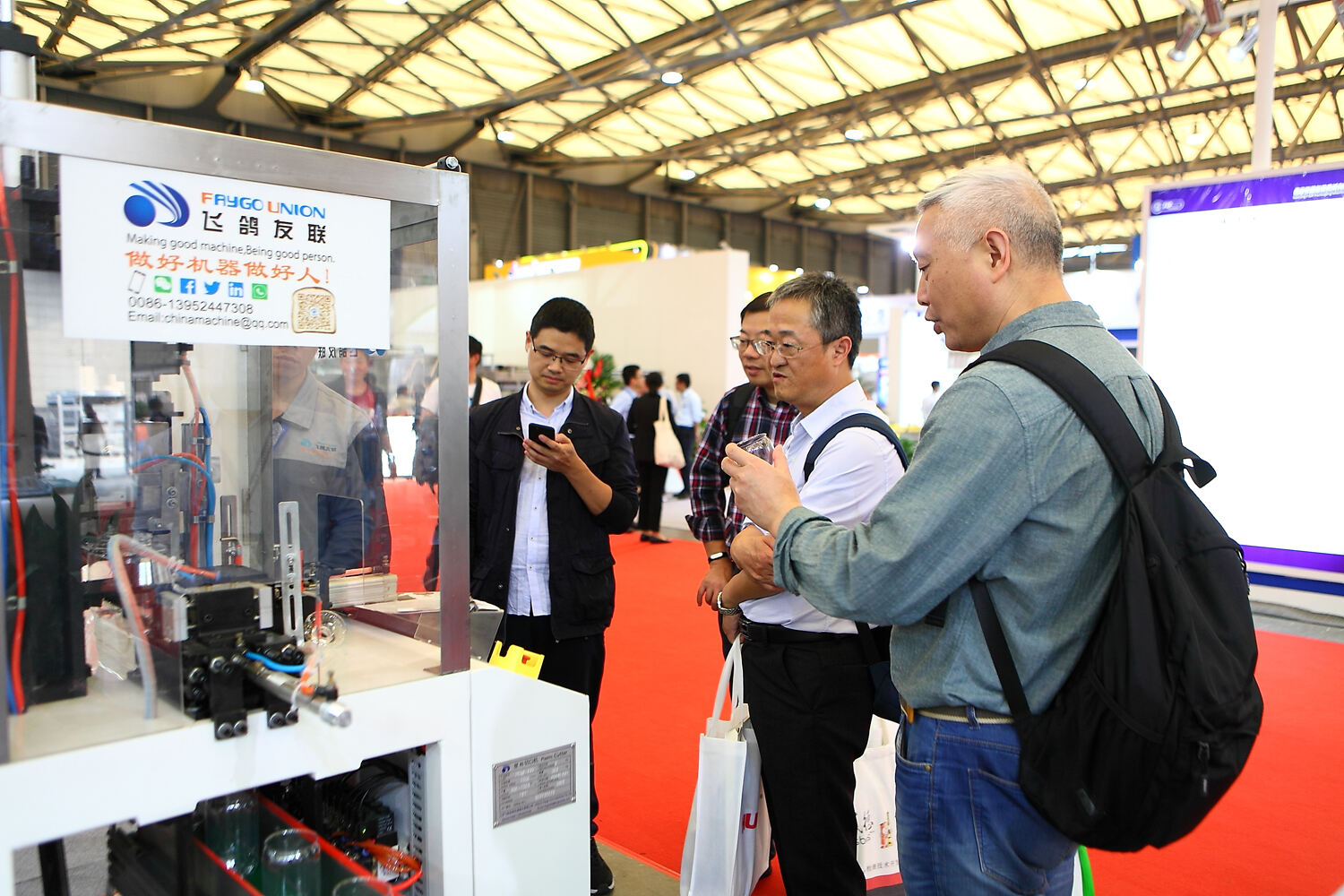

Launching the Automatic Plastic Mineral Water bottle Blowing Machine 4 Cavity! This phenomenal item, delivered by Feige Youlian Machinery, will be the perfect solution when it comes to container company manufacturing. This product was created to blow plastic containers by having a capability maximum of, and it surely will create just as much as 4 containers at any moment, rendering it extremely efficient for high-volume manufacturing.

One of the most impressive top features of the Faygo Union Automatic Bottle Blowing device is its simplistic design. There's no necessity your can purchase any advanced level abilities which are often technical knowledge to make use of this device. The touch screen that is intuitive guidance and control over the entire manufacturing procedure, making it simple for one to utilize. The equipment itself could be extremely durable and can withstand the rigors of day-to-day usage without wearing down or becoming damaged.

Another asset that is advantageous of device is you can somewhat reduce handbook work while increasing manufacturing effectiveness it really is completely automatic, what this means is. This particular feature can certainly be ideal for keeping constant quality of items as the device does not exhausted, beneath the stress very same heat the apparatus provides the exact quality container every time that is same.

Furthermore, this Faygo Union Automatic Bottle Blowing device is eco-friendly as a result of its power low usage. The gear utilizes an heating that is advanced that somewhat decreases energy usage.

Feige Youlian Machinery includes a track record of creating devices which could additionally be top-quality the Faygo Union Automatic Plastic Mineral Water Bottle Blowing device isn't any exclusion. It is designed to meet with the greatest criteria of security and dependability, making certain your manufacturing operates efficiently with just minimal downtime.

Model |

FG4 |

FG6 |

FG8 |

||||

Mold number(piece) |

4 |

6 |

8 |

||||

Max capacity(BPH) |

7200 |

9600 |

12000 |

||||

Bottle specification

|

Max volume(ml) |

2000 |

2000 |

2000 |

|||

Max height(mm) |

328 |

328 |

328 |

||||

Round bottle max diameter(mm) |

105 |

105 |

105 |

||||

Square bottle max diagonal(mm) |

115 |

115 |

115 |

||||

Preform specification

|

Suitable inner bottle neck(mm) |

20-25 |

20-25 |

20-25 |

|||

Max preform length(mm) |

150 |

150 |

150 |

||||

Electricity

|

Total installation power(kW) |

51 |

74 |

97 |

|||

Heating oven total power(kW) |

46 |

69 |

92 |

||||

Heating oven real power(kW) |

26 |

40 |

50 |

||||

Voltage/frequency(V/Hz) |

380(50Hz) |

380(50Hz) |

380(50Hz) |

||||

Allowed voltage fluctuation range |

±10% |

±10% |

±10% |

||||

Compressed air |

Pressure(bar) |

30 |

30 |

30 |

|||

Air consumption(㎥/min) |

4 |

5.5 |

7 |

||||

Cooling water

|

Mold water |

Pressure(bar) |

4-6 |

4-6 |

4-6 |

||

Temperature regulation range(℃) |

6-13 |

6-13 |

6-13 |

||||

Flow rate(L/min) |

45 |

45 |

45 |

||||

Oven water |

Pressure(bar) |

4-6 |

4-6 |

4-6 |

|||

Temperature regulation range(℃) |

6-13 |

6-13 |

6-13 |

||||

Flow rate(L/min) |

22 |

22 |

22 |

||||

Machine specification |

Machine dimension(m)(L*W*H) |

Machine dimension(m)(L*W*H) |

3.3*1*2.3 |

4.3*1*2.3 |

4.8*1*2.3 |

||

Machine weight(Kg) |

Machine weight(Kg) |

3200 |

4000 |

4500 |

|||

Item |

Magnetic valve |

Servo system |

Frequency inverter PLC |

Blowing valve |

One-way valve |

Reducing valve |

Cylinder |

Touch screen |

Throttle valve |

||||

Brand |

FESTO |

Panasonic |

MITSUBISHI |

Parker |

FESTO |

DURAY |

Origin |

Germany |

Japan |

Japan |

USA |

Germany |

Germany |

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy