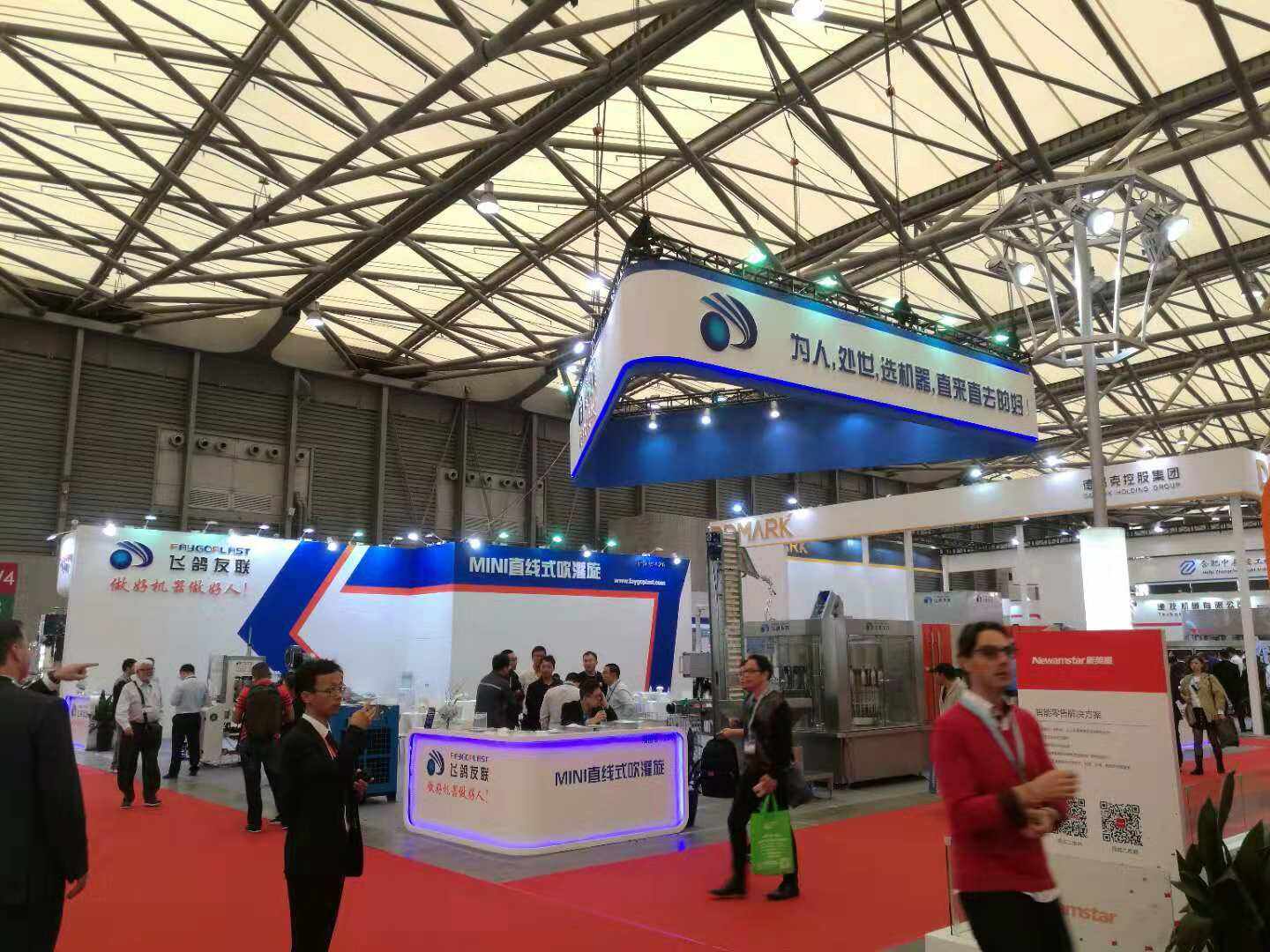

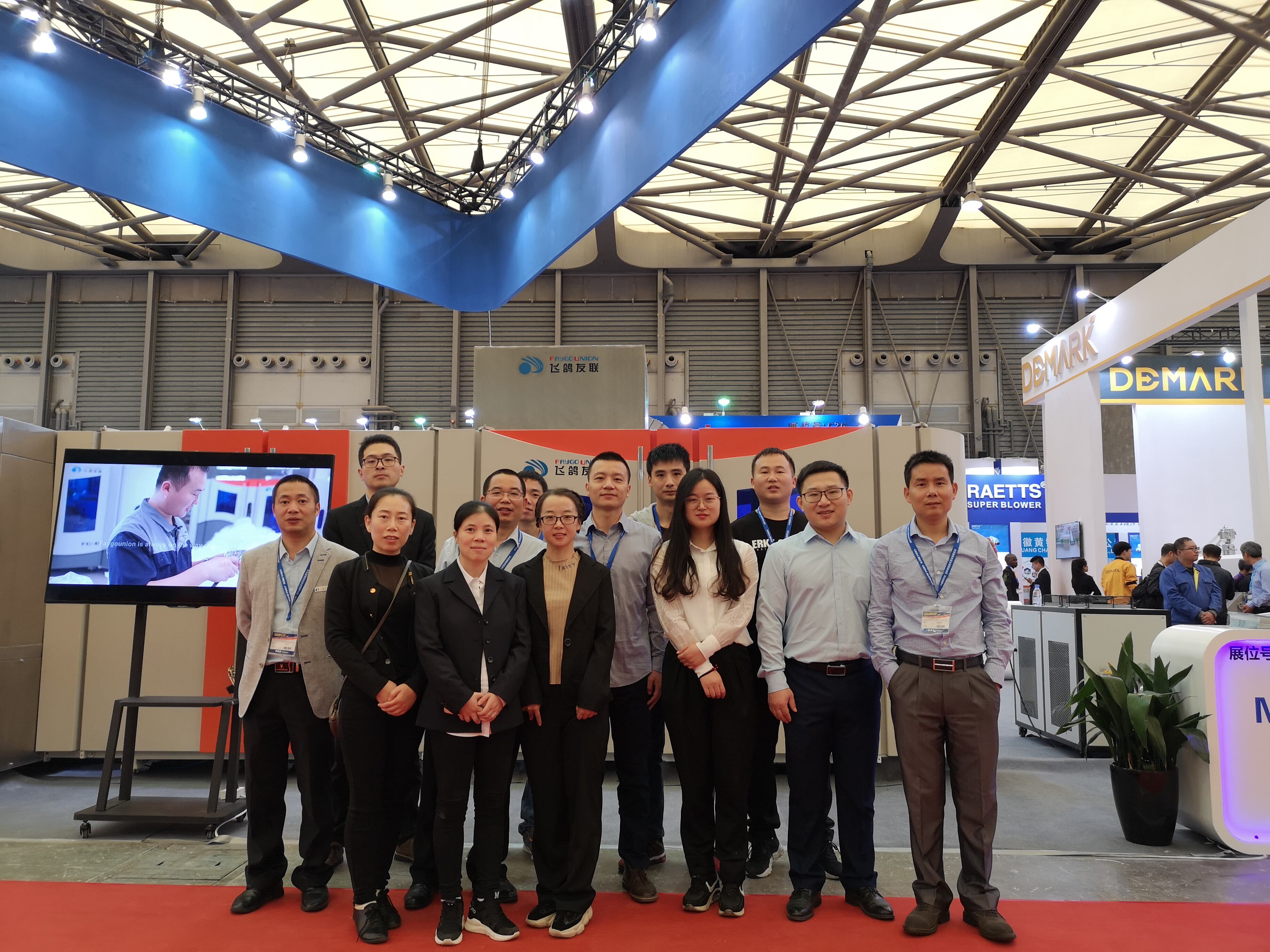

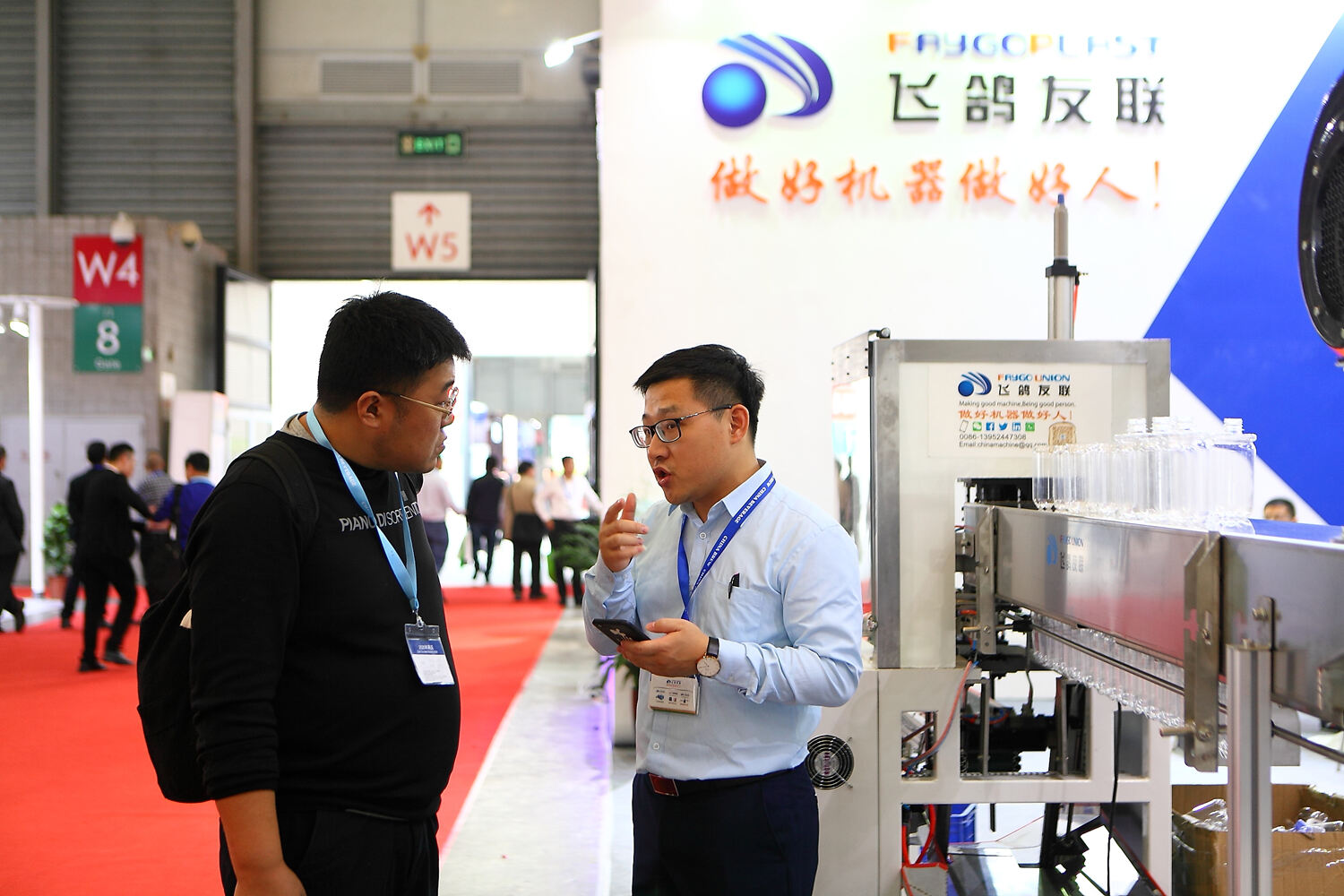

Faygo Union’s Automatic Plastic Bottle Water Drinks Filling Machine And Blowing Production Line is the ideal solution for companies that wants to improve their production procedures. Faygo Union is a top-notch brand name that provides top-quality products and services to fulfill what's needed of companies worldwide. This method features higher level technology, high manufacturing capability, and superior gratification.

The Faygo Union’s Automatic Plastic Bottle Water Drinks Filling Machine And Blowing Production Line was created to fill up plastic bottle with water products for a big scale. This product can fill as much as 24000 containers each hour that makes it a fantastic choice for companies that are trying to boost their manufacturing ability. The unit super easy to use, needing minimal manual intervention.

The production line features advanced technology that ensures that water bottles are filled up effectively and accurately. Along with the automatic control, organizations can make sure that the machine runs efficiently, decreasing the chance of downtime. This manufacturing line was made to save you money and time while increasing manufacturing effectiveness.

Also, the Faygo Union’s Automatic Plastic Bottle Water Drinks Filling Machine And Blowing Production Line features a blowing area that was meant to make plastic bottles. This feature ensures that companies won’t need not buy various machines to make plastic bottles, which saves them cash. Also, the plastic bottles made are of top quality and sturdy.

In relation to upkeep, the Faygo Union’s Automatic Plastic Bottle Water Drinks Filling Machine And Blowing Production Line was created to reduce downtime. This is easy to keep up and it was created to offer long-lasting performance. This product can last for a long time, giving value to companies with appropriate upkeep.

Finally, the Faygo Union’s Automatic Plastic Bottle Water Drinks Filling Machine And Blowing Production Line was made with the environment in mind. This machine is eco-friendly, reducing power usage and manufacturing waste. This feature helps it be a sustainable choice for companies seeking to reduce their carbon impact

Model | FG4 | FG6 | FG8 | ||||

Mold number(piece) | 4 | 6 | 8 | ||||

Max capacity(BPH) | 7200 | 9600 | 12000 | ||||

Bottle specification | Max volume(ml) | 2000 | 2000 | 2000 | |||

Max height(mm) | 328 | 328 | 328 | ||||

Round bottle max diameter(mm) | 105 | 105 | 105 | ||||

Square bottle max diagonal(mm) | 115 | 115 | 115 | ||||

Preform specification | Suitable inner bottle neck(mm) | 20-25 | 20-25 | 20-25 | |||

Max preform length(mm) | 150 | 150 | 150 | ||||

Electricity | Total installation power(kW) | 51 | 74 | 97 | |||

Heating oven total power(kW) | 46 | 69 | 92 | ||||

Heating oven real power(kW) | 26 | 40 | 50 | ||||

Voltage/frequency(V/Hz) | 380(50Hz) | 380(50Hz) | 380 50Hz | ||||

Allowed voltage fluctuation range | ±10% | ±10% | ±10% | ||||

Compressed air | Pressure(bar) | 30 | 30 | 30 | |||

Air consumption(㎥/min) | 4 | 5.5 | 7 | ||||

Cooling water | Mold water | Pressure(bar) | 4-6 | 4-6 | 4-6 | ||

Temperature regulation range(℃) | 6-13 | 6-13 | 6-13 | ||||

Flow rate(L/min) | 45 | 45 | 45 | ||||

Oven water | Pressure(bar) | 4-6 | 4-6 | 4-6 | |||

Temperature regulation range(℃) | 6-13 | 6-13 | 6-13 | ||||

Flow rate(L/min) | 22 | 22 | 22 | ||||

Machine specification | Machine dimension(m) L*W*H | Machine dimension(m)(L*W*H) | 3.3*1*2.3 | 4.3*1*2.3 | 4.8*1*2.3 | ||

Machine weight Kg | Machine weight(Kg) | 3200 | 4000 | 4500 | |||

Item | Magnetic valve | Servo system | Frequency inverter PLC | Blowing valve | One-way valve | Reducing valve |

Cylinder | Touch screen | Throttle valve | ||||

Brand | FESTO | Panasonic | MITSUBISHI | Parker | FESTO | DURAY |

Origin | Germany | Japan | Japan | USA | Germany | Germany |

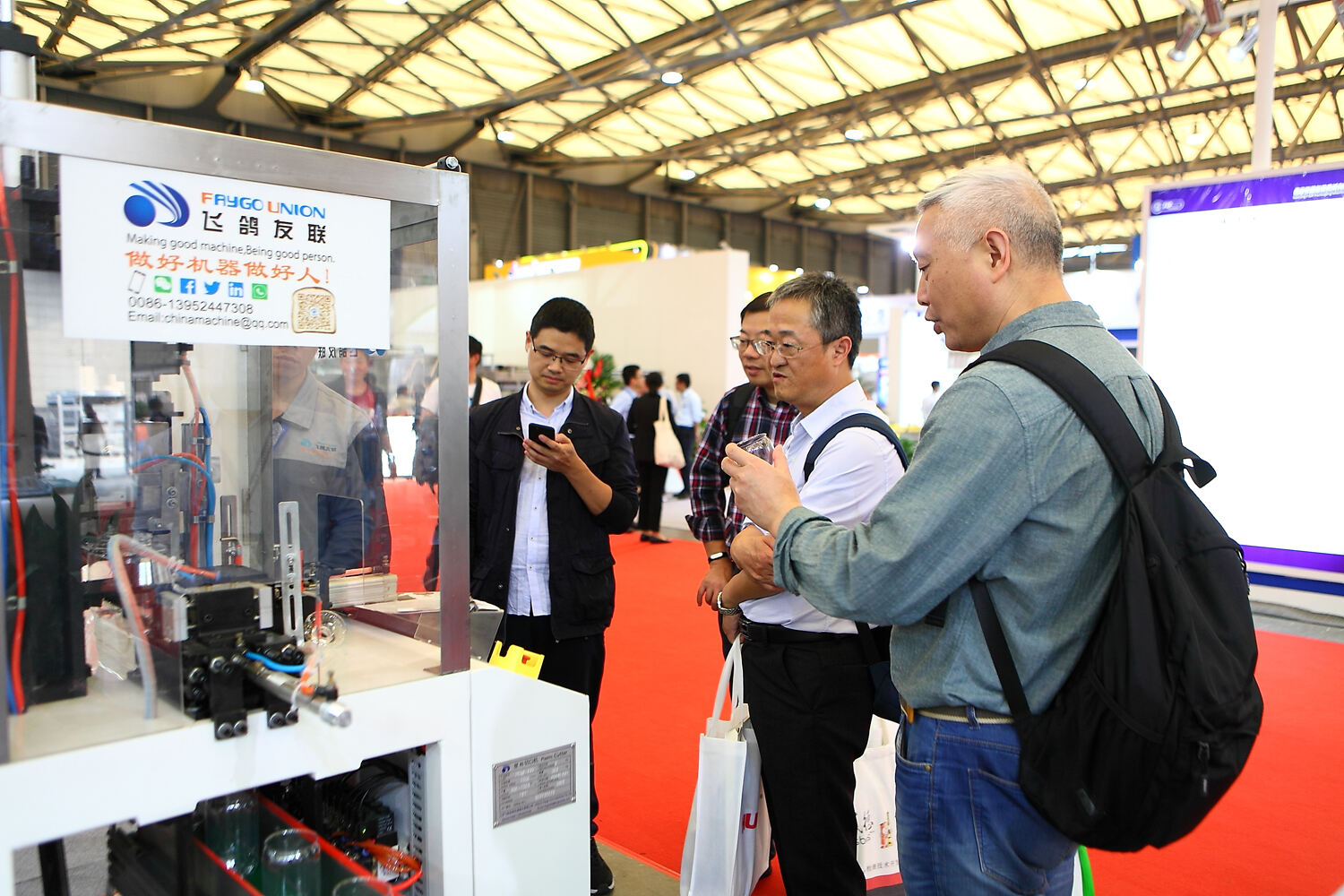

1. Q: Are you a factory or trading company

A: We are a factory covering more than 20000㎡

2. Q:What can you buy from us

A: Plastic machinery, Pipe production line, Plate production line, Profile production line, Blow Molding Machine and so on

3. how can we guarantee quality

Always a pre-production sample before mass production;

Always final Inspection before shipment.4. Q:What can you provide for after-sale service

A: 12 months Warranty for Mechanical part, main parts is made of high tool steel by special quenching treatment, with high corrosion resistance and wear resistance. We also provide equipment repair services for life. For long-term cooperation, we always provide good quality, good price and good service to customer

5. Q: How can we visit your company

A: Our factory is in Feixiang Road, Fenghuang Town, Zhangjiagang City, Jiangsu Province, China. About 2.5hours from Shanghai Pudong International Ariport. Welcome everyone to visit our factory, we will show you our machines

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy