Finding a powerful and dependable solution for your container and moulding requirements? Search no further than Faygo Union’s PET Bottle Blowing-Filling-Capping Combiblock | Efficient 3-in-1 Solution for Bottle Production and Moulding.

This combi block allows you to blow, fill, and cap containers all in one streamlined process along with its advanced 3-in-1 design. This implies quicker manufacturing times, paid off labor expenses, much less chances of contamination or mistake.

Feige Youlian Machinery is a trusted brand in the industry, popular for their quality items and revolutionary designs. The FAYGO’s PET Bottle Blowing-Filling-Capping Combiblock is not any exclusion, supplying an advanced solution to any container manufacturing requirements.

This combi block is fantastic for various liquids, from water in bottles and soda pops to detergents, cosmetic makeup products, and pharmaceuticals. Its versatile designs are designed for containers of numerous size and shapes.

One of the key benefits of the FAYGO’s PET Bottle Blowing-Filling-Capping Combiblock is its power effectiveness. This combi block operates on a single engine to power all three procedures unlike old-fashioned container manufacturing techniques, which need split blowing, filling, and capping devices. This implies reduced power consumption, paid off upkeep expenses, and lower ecological impact.

The FAYGO’s PET Bottle Blowing-Filling-Capping Combiblock is easy to use and continue maintaining along with its power effectiveness. Its intuitive touchscreen display makes it an effortless procedure and monitoring of manufacturing procedures, while its top-quality components guarantee durable performance and minimal downtime

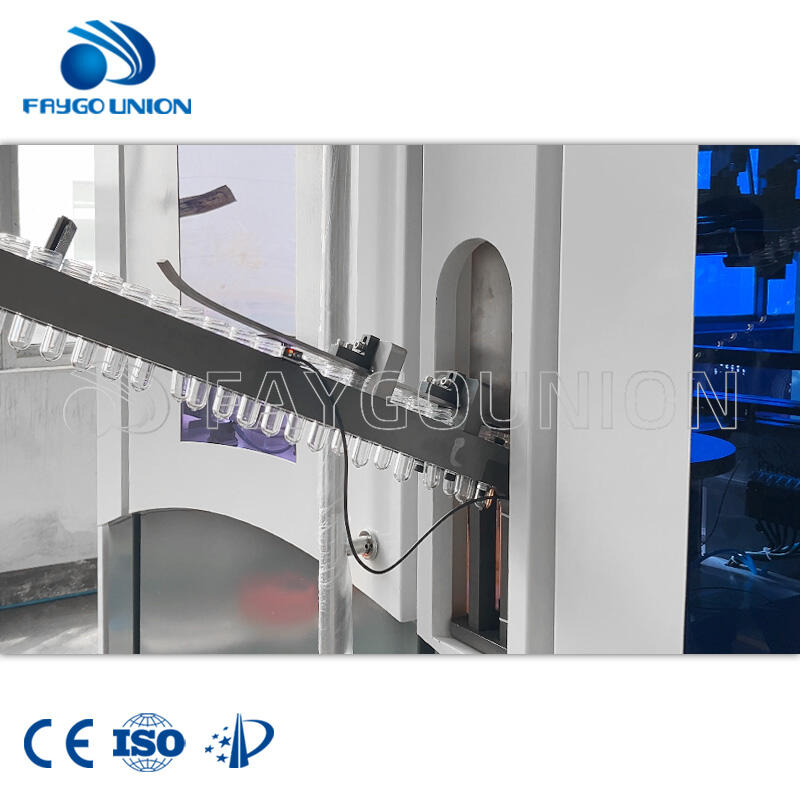

Small linear blowing-filling-capping integrated equipment

The speed of this series of models is positioned at ten thousand-twenty thousand bottles per hour

Suitable for small batch and multi specification customized water and other needs;

This series of models is independently developed and has independent intellectual property rights, thirteen national patents have been obtained, including five national invention patents

Jiangsu Feige Youlian Machinery Co., Ltd. specializes in mini linear blow irrigation and rotation, saving you factory area

As CGX6-16-8, 10000 bottles per hour, using 500ml bottles as an example

The machine is only 7 meters long and 1.6 meters wide

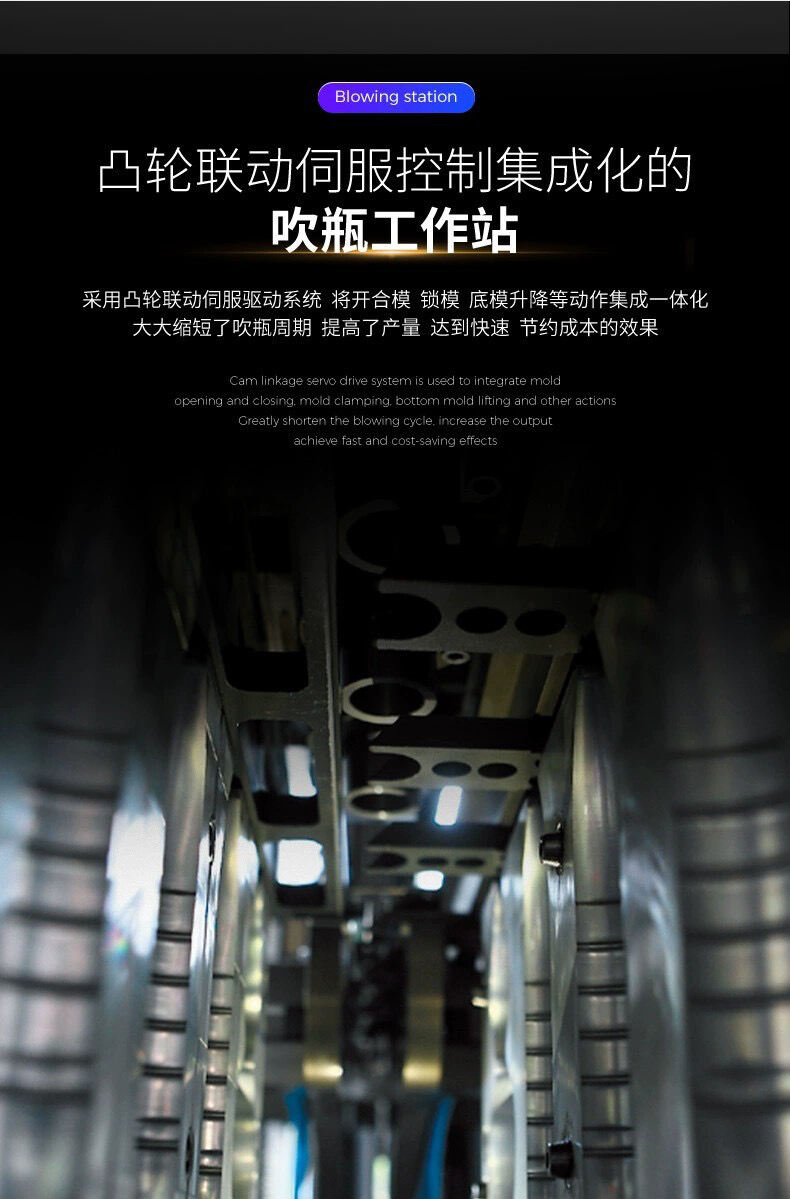

Integrated cam linkage servo control

Blowing bottle work station

Cam linkage servo drive system is used to integrate mold

opening and closing, mold clamping, bottom mold lifting and other actions

Greatly shorten the blowing cycle, increase the output

achieve fast and cost-saving effects

Heating system with small pitch

The heating head is arranged with a small pitch of 38. mm

which saves more than 3096 energy than the traditional heating furnace thus achieving the cost-saving

effect. The blowing system and the waste heat exhaust system are set up to basically ensure the constant temperature of the blowing area

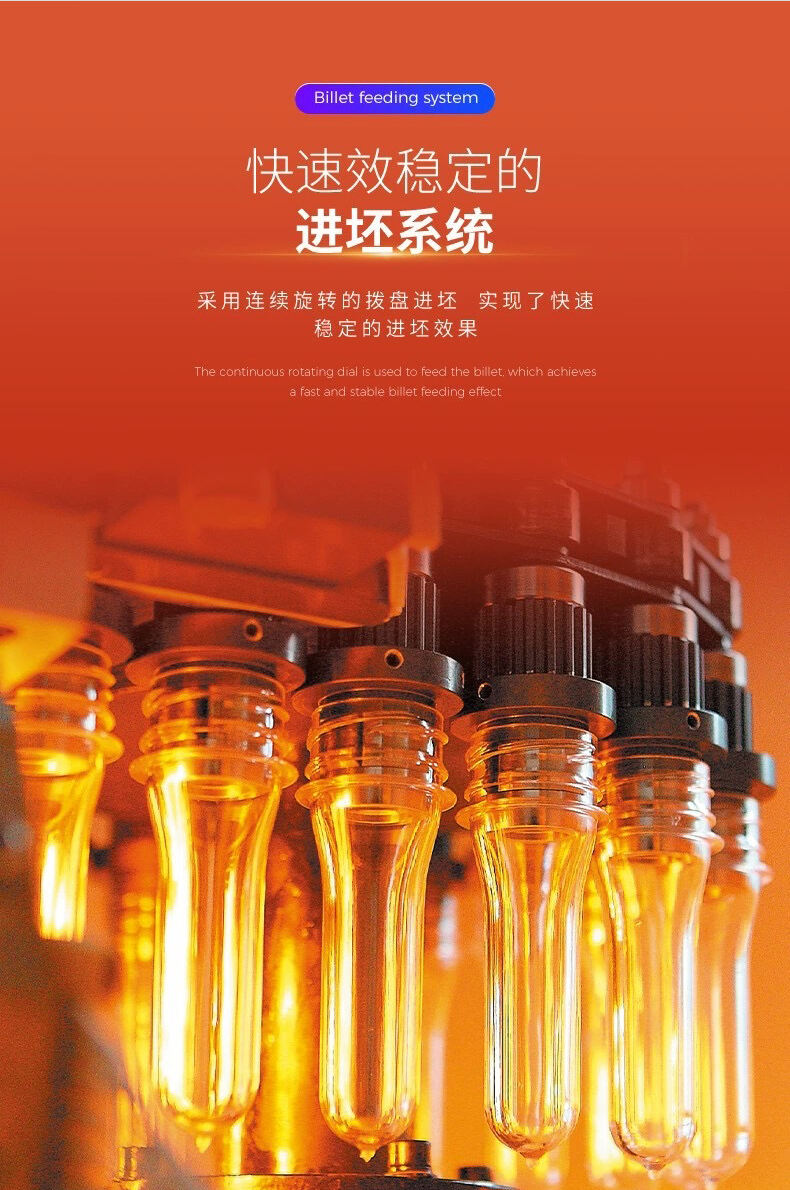

Billet feeding system

The continuous rotating dial is used to feed the billet. which achieves a fast and stable billet feeding effect

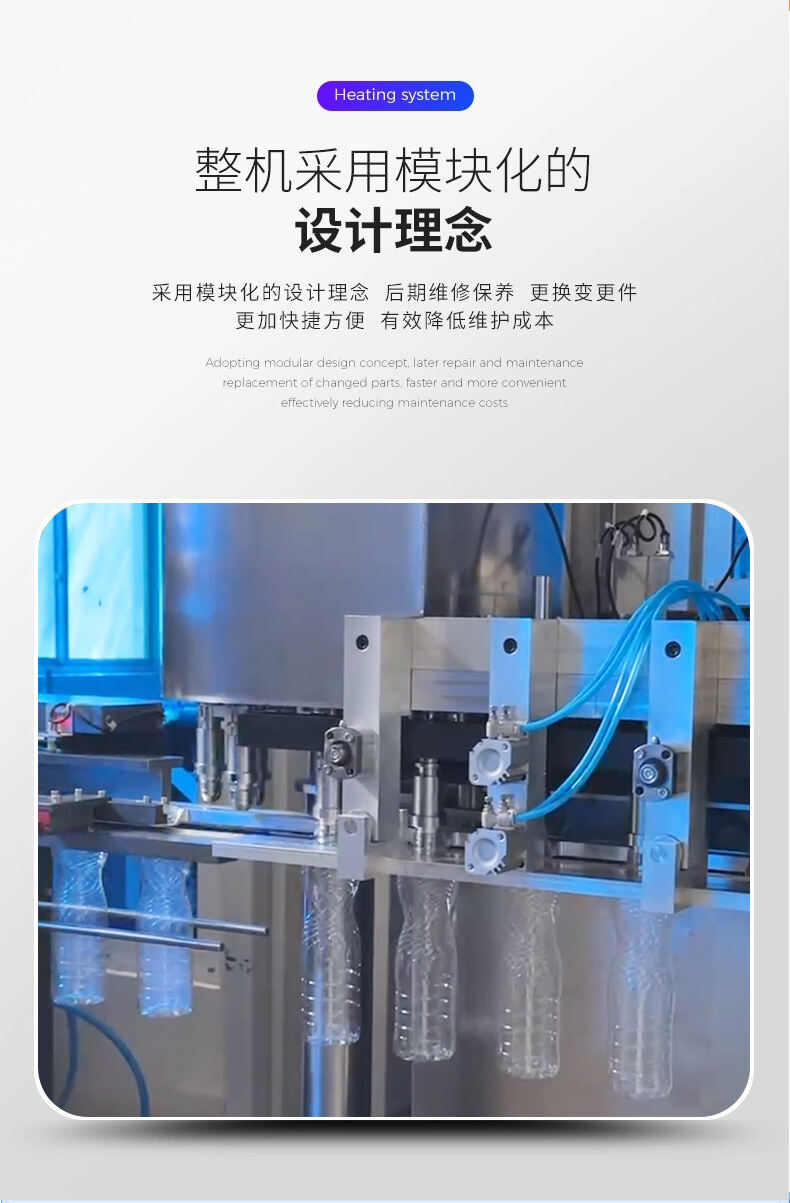

Heating system

Adopting modular design concept later repair and maintenance replacement of changed parts faster and more convenient effectively reducing maintenance costs

1. High-quality equipment and highly competitive market prices can bring you more profits 2. We have a one-year warranty and can provide long-term technical support

3. Years of experience in the research of plastic extruders enable us to solve most of the problems and improve efficiency

4. Send Your Inquire Details In The Below Click "Send" Now