FAYGO Union brings to you the newest in revolutionary technology which consists of PET Bottle Blowing and Filling Combiblock device. This advanced equipment was made to add the bottle blowing, filling, and capping procedures to provide you a seamless and efficient bottling procedure.

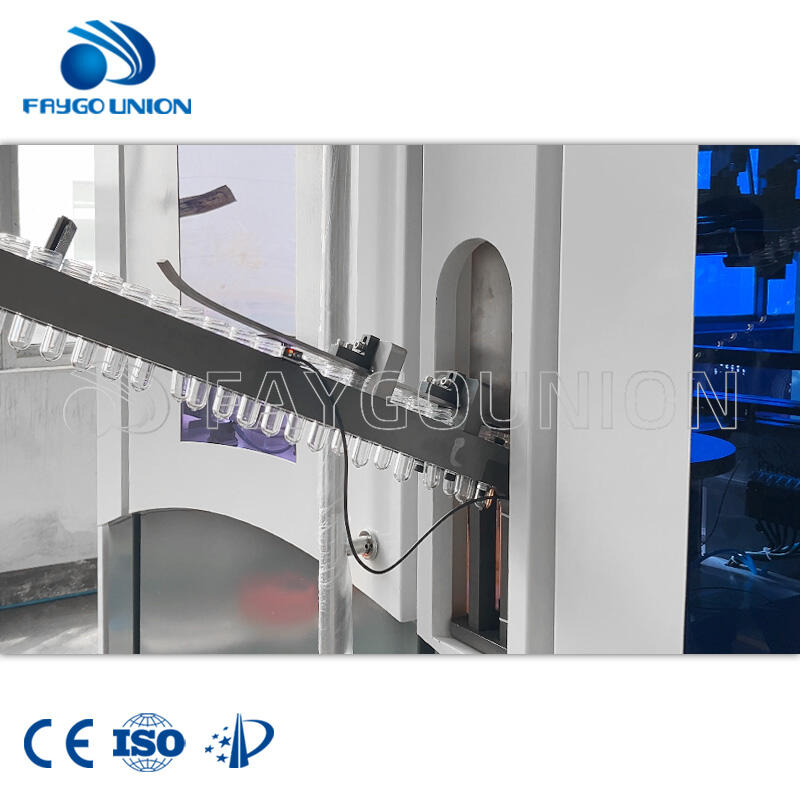

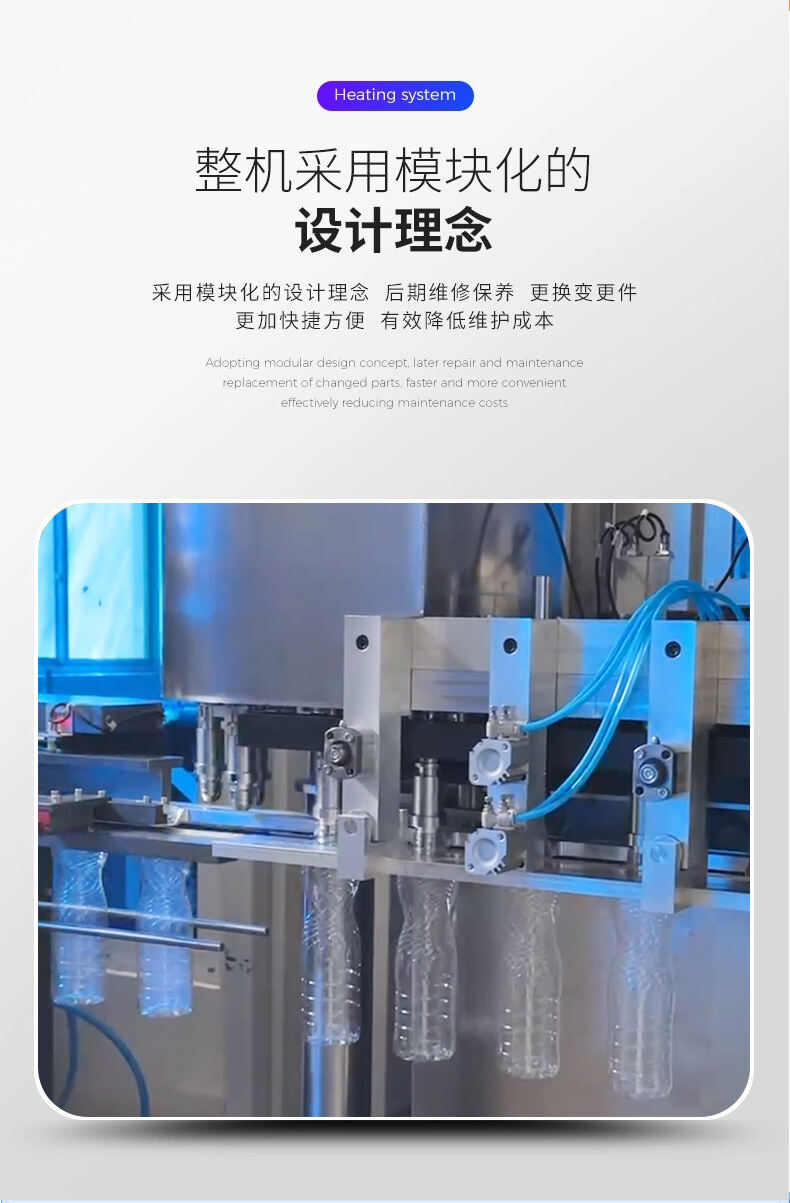

The equipment was created with a built-in blower and filler system that guarantees most of the containers are manufactured and filled in one main location. This implies you can streamline your manufacturing process, boost your production, and save well on expenses. These devices are made with a lightweight design which means that no need for big area in setting it.

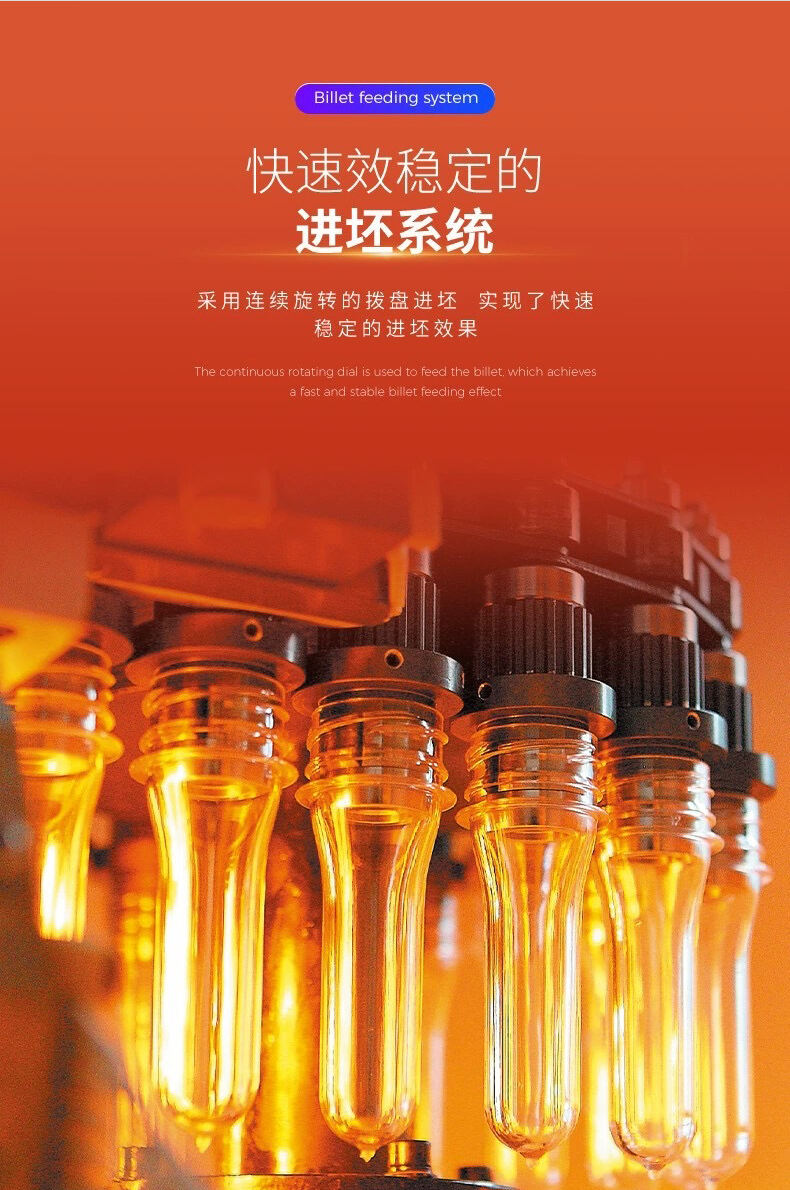

Among the best options that come with the Faygo Union’s PET Bottle Blowing and Filling Combiblock machine is its capacity to manage different container forms. Whether you have to fill 20ml to 2000ml containers, this machine can adjust to accommodate your particular needs. This freedom saves you cash on purchasing numerous machine for various bottle.

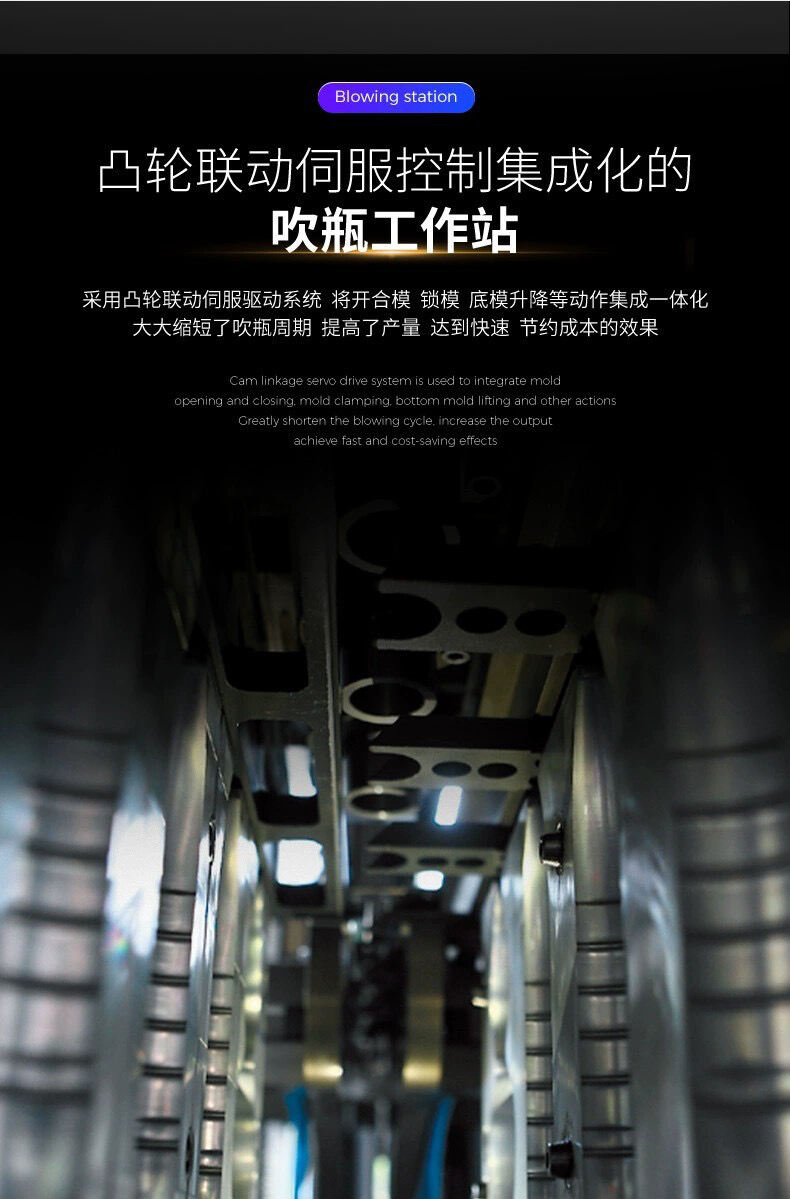

Furthermore, this machine’s blower system is energy-efficient, as it uses a high-pressure atmosphere compressor to blow the containers instead of technical system. This not only helps you save on power expenses but in addition, decreases the ecological effect as it minimizes carbon emissions.

Faygo Union's PET Bottle Blowing and Filling Combiblock machine was manufactured with a user-friendly program and easy-to-use settings. Operators can easily adjust the machine’s settings to meet your particular manufacturing needs. The machine was designed with automated sensors that detect any abnormalities in the container manufacturing procedure, such as container jams or misalignments, and immediately shuts the machine to prevent harm.

Additionally, the machine was made with top-notch materials that ensure durability. The blend of steel and aluminum guarantees the product can withstand harsh manufacturing and extreme climate conditions

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy