Are you tired and sick of sluggish and ineffective bottle manufacturing? Look no further than FAYGO’s High-Speed PET Bottle Blowing-Filling-Capping Combiblock Machine | 3-in-1 Solution for Efficient Production! This 3-in-1 solution offers an extensive and efficient manufacturing procedure to your bottling requirements.

Our machine combines the actions of blowing, filling, and capping in one single seamless procedure, assisting you to save time and expenses. Having a high-speed ability, you can create just as much as 12,000 containers each hour, ensuring your manufacturing needs are met quickly and effectively.

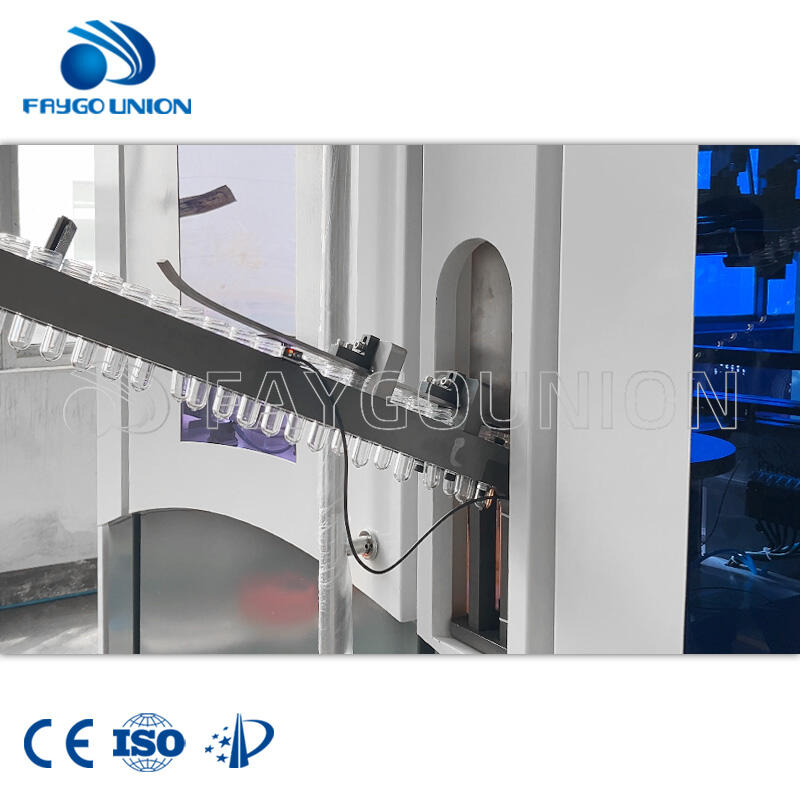

The Faygo Union machine was produced with higher accuracy rate and technology elements. Our machine’s servo control system guarantees an accurate filling and minimizes waste. Our blowing feature comes with a preform automatic feeding system, making a reliable and dependable production procedure.

Our capping section makes use of a magnetic torque, ensuring tight and safe caps, while the flexible design allows for the usage of numerous kinds and sizes. The machine was constructed with an automatic lubrication, promoting longevity and reducing maintenance requirements.

The Faygo Union’s High-Speed PET Bottle Blowing-Filling-Capping Combiblock Machine would work various container kinds, including water, non-alcoholic drink, juice, and much more. The equipment's lightweight design allows for effortless procedure and installation, making it perfect for small to medium-sized companies

Small linear blowing-filling-capping integrated equipment

The speed of this series of models is positioned at ten thousand-twenty thousand bottles per hour

Suitable for small batch and multi specification customized water and other needs;

This series of models is independently developed and has independent intellectual property rights, thirteen national patents have been obtained, including five national invention patents

Jiangsu Feige Youlian Machinery Co., Ltd. specializes in mini linear blow irrigation and rotation, saving you factory area

As CGX6-16-8, 10000 bottles per hour, using 500ml bottles as an example

The machine is only 7 meters long and 1.6 meters wide

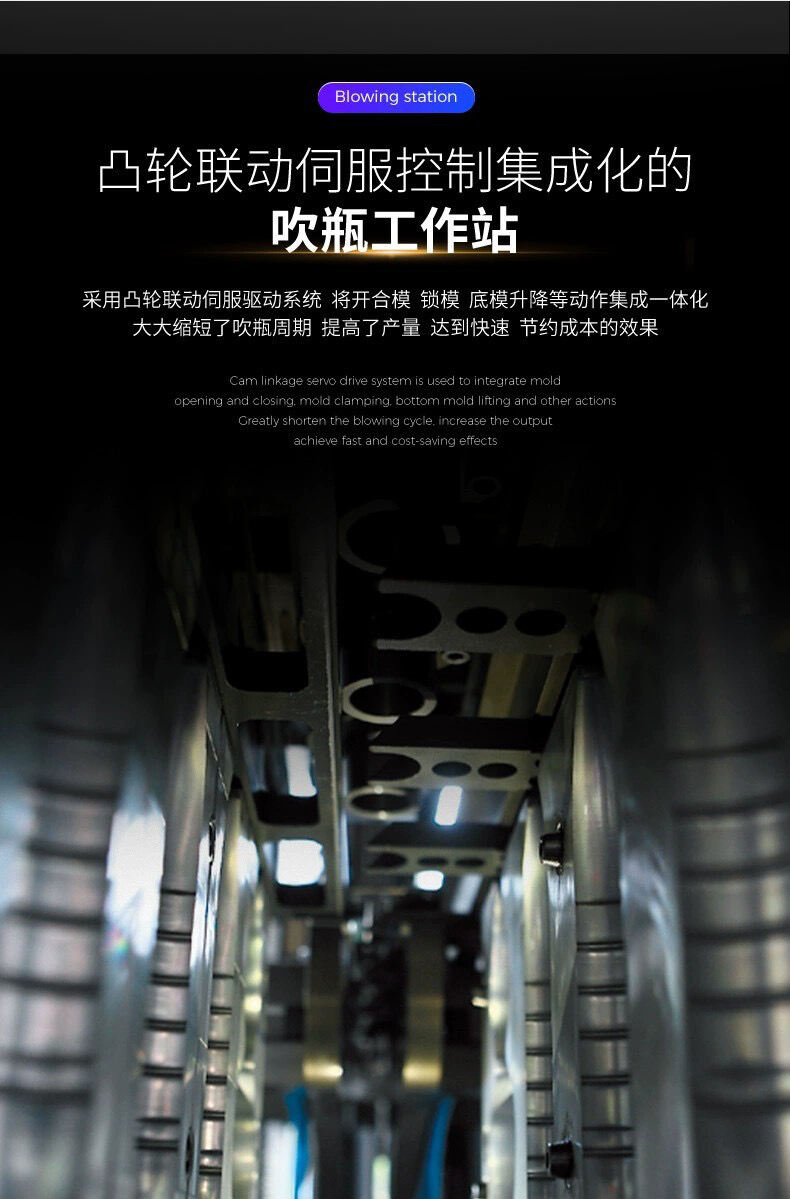

Integrated cam linkage servo control

Blowing bottle workstation

Cam linkage servo drive system is used to integrate mold

opening and closing, mold clamping, bottom mold lifting and other actions

Greatly shorten the blowing cycle, increase the output

achieve fast and cost-saving effects

Heating system with small pitch

The heating head is arranged with a small pitch of 38. mm

which saves more than 3096 energy than the traditional heating furnace thus achieving the cost-saving effect. The blowing system and the waste heat exhaust system are set up to basically ensure the constant temperature of the blowing area

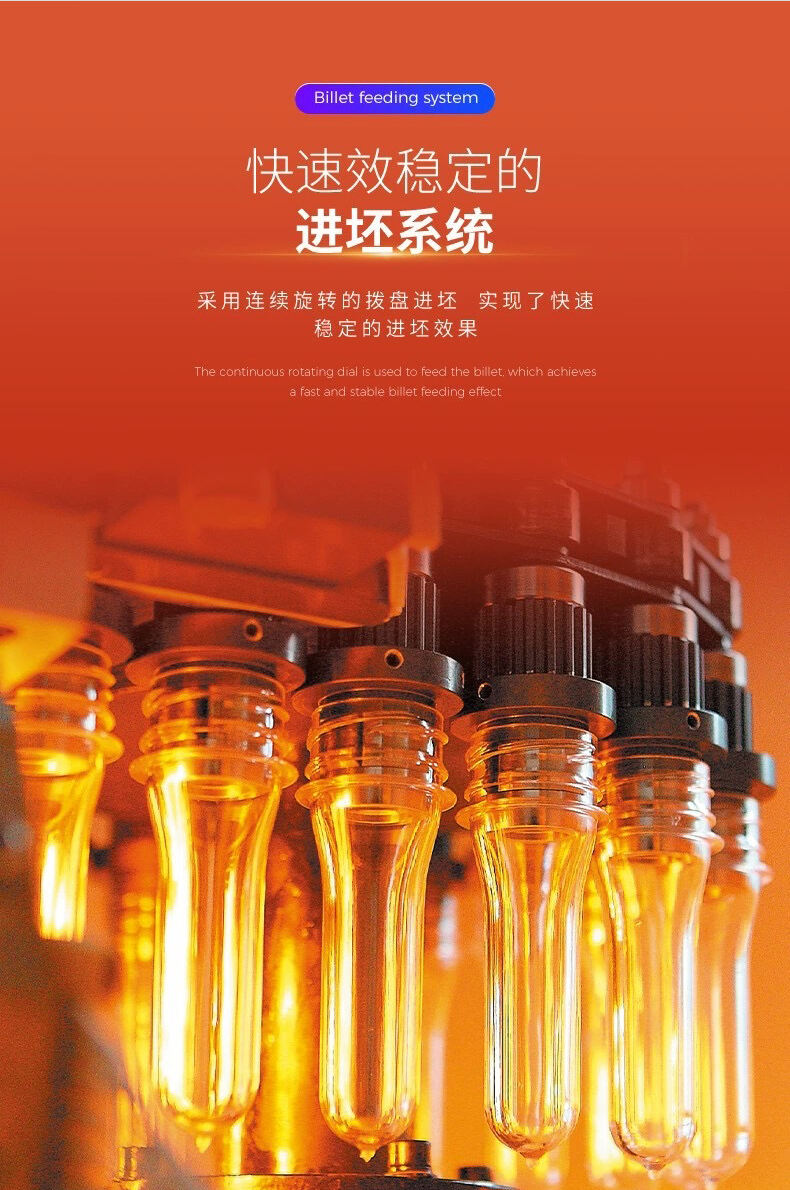

Billet feeding system

The continuous rotating dial is used to feed the billet. which achieves a fast and stable billet feeding effect

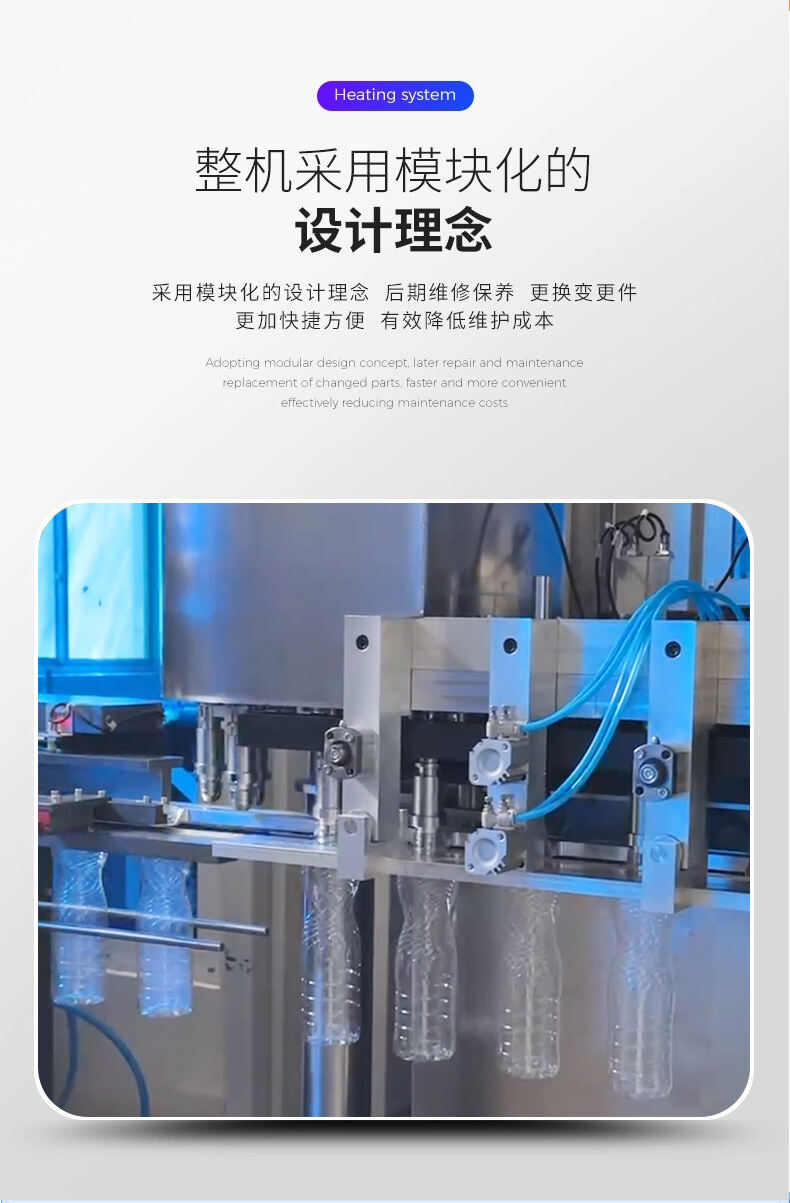

Heating system

Adopting modular design concept. later repair and maintenance replacement of changed parts faster and more convenient, effectively reducing maintenance costs

1. High-quality equipment and highly competitive market prices can bring you more profits. 2. We have a one-year warranty and can provide long-term technical support

3. Years of experience in the research of plastic extruders enable us to solve most of the problems and improve efficiency

4. Send Your Inquire Details In The Below Click "Send" Now