Faygo Union

4 cavity low price fully automatic high speed small PET oil plastic bottle blowing molding machine. This device is done with more impressive range technology and features which makes it something superior.

The 4-cavity design related to device is wonderful for tiny to production medium-sized that need high effectiveness and manufacturing quick. The unit is beneficial at creating just as much as 4800 containers each hour, making this a range organizations top need high-speed manufacturing and never have to sacrifice quality.

The lower cost regarding the device can make it an investment good is of great interest for companies looking for economical solutions. The Faygo Union gear is low on upkeep and simple to work, that makes it a selection ideal organization with restricted resources or spending plan constraints.

These devices can be completely automated and developed to work seamlessly minus the intervention peoples. The automatic top features associated with equipment consist of automatic preform loading, heating, and bottle blowing. With one of these features, companies can lessen the necessity for skilled work and minimize their manufacturing considerably costs.

Faygo Union's 4 cavity cost low automated rate high animal oil synthetic container blowing molding device normally fashioned with security in your mind. These devices have safety a couple of such as a computerized security that appears in case of any breakdown or mistake. These devices provide a situation urgent switch you can use to shut the device down just in case there is any security dilemmas.

Your dog material found in the containers made by this product is of quality, rendering it perfect for oil other products fluid. The containers produced are strong, durable, whilst having a finish glossy making them a great selection for retail packaging.

|

Model

|

FG4

|

FG4F

|

FG6

|

FG8

|

|

Cavity number

|

4 cav

|

4 cav

|

6cav

|

8cav

|

|

Operation speed

|

6500-8000 BPH

|

4000-4500BPH

|

6500-8000 BPH

|

6500-8000 BPH

|

|

Operation power

|

25 kw

|

28kw

|

30kw

|

45kw

|

|

Max volumn

|

2000ml

|

1500ml

|

2000ml

|

750ml

|

|

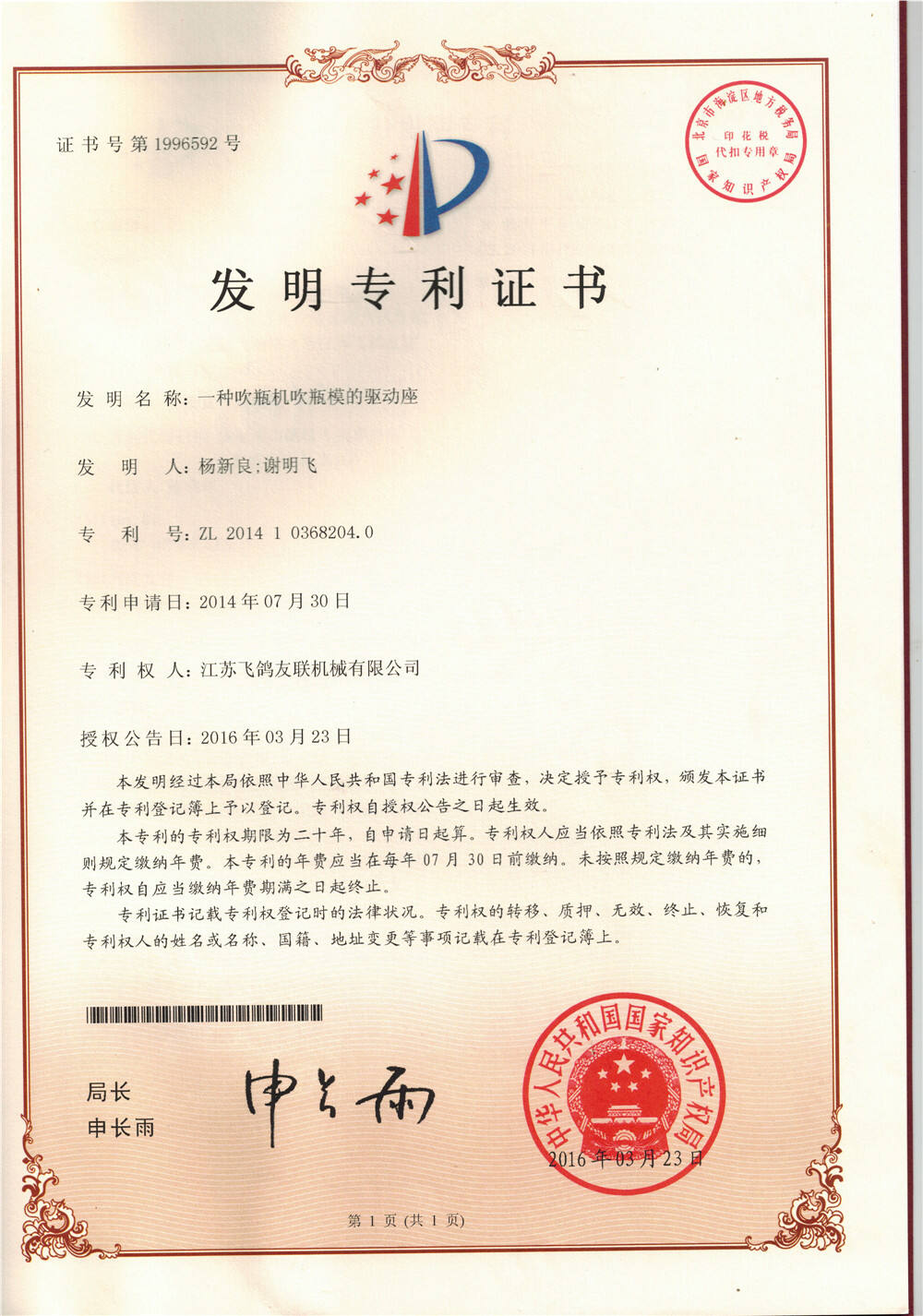

Drive holder for blow molding machine of blowing machine

|

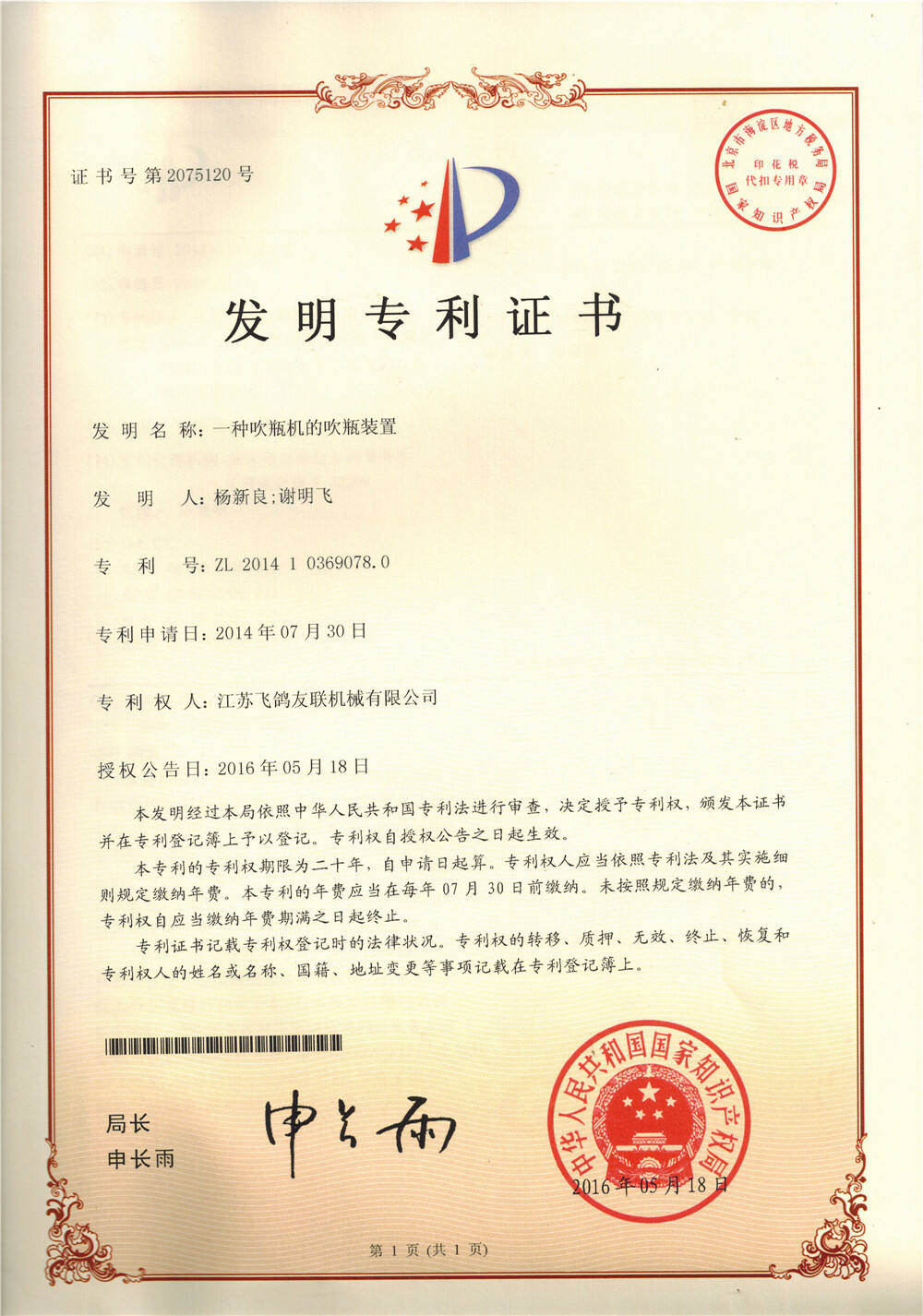

Blowing device for blow molding machine

|

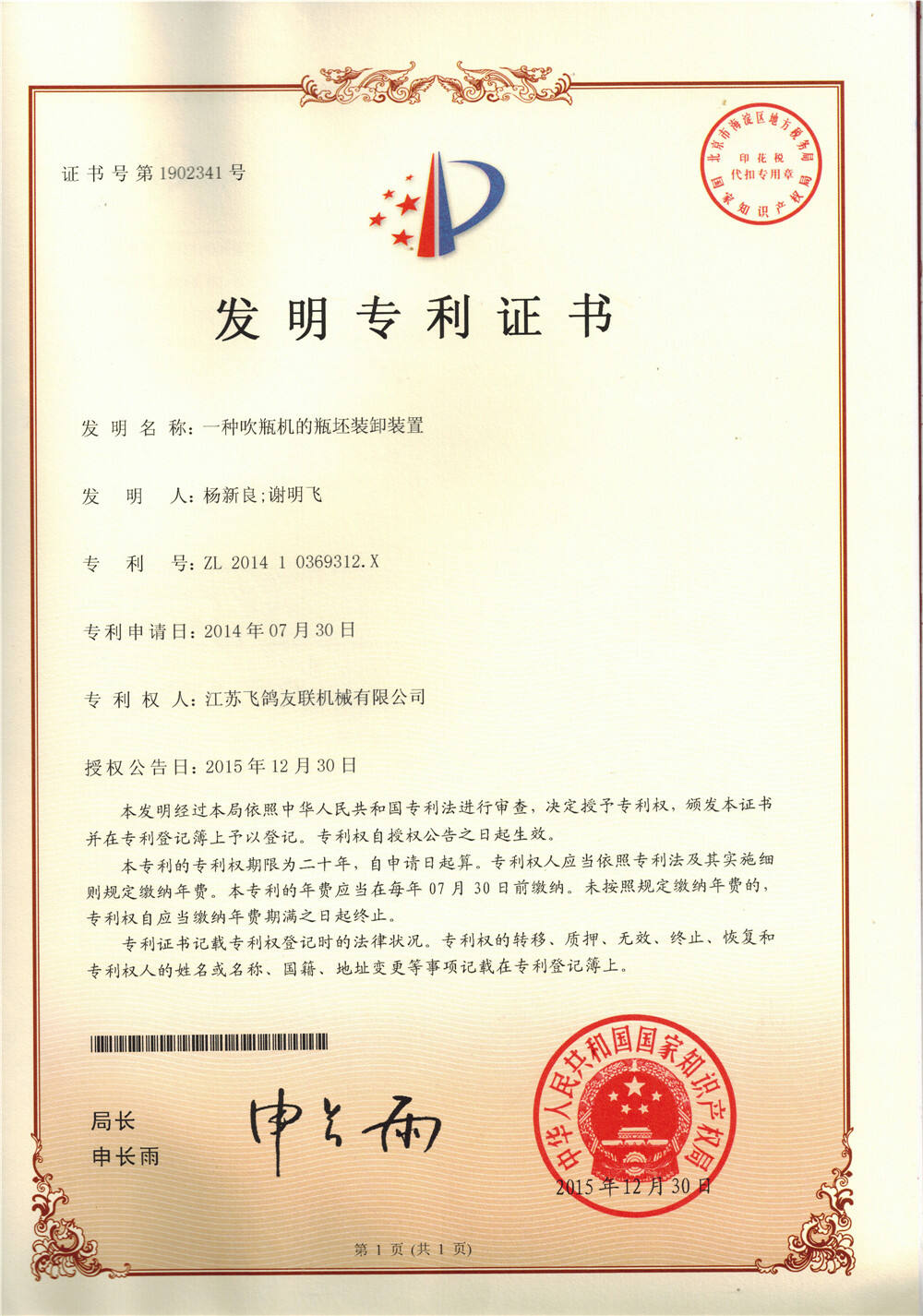

Bottle blank handling device for blow molding machine

|

The Opening and Closing Device of the f a Bottle Blower

|

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy