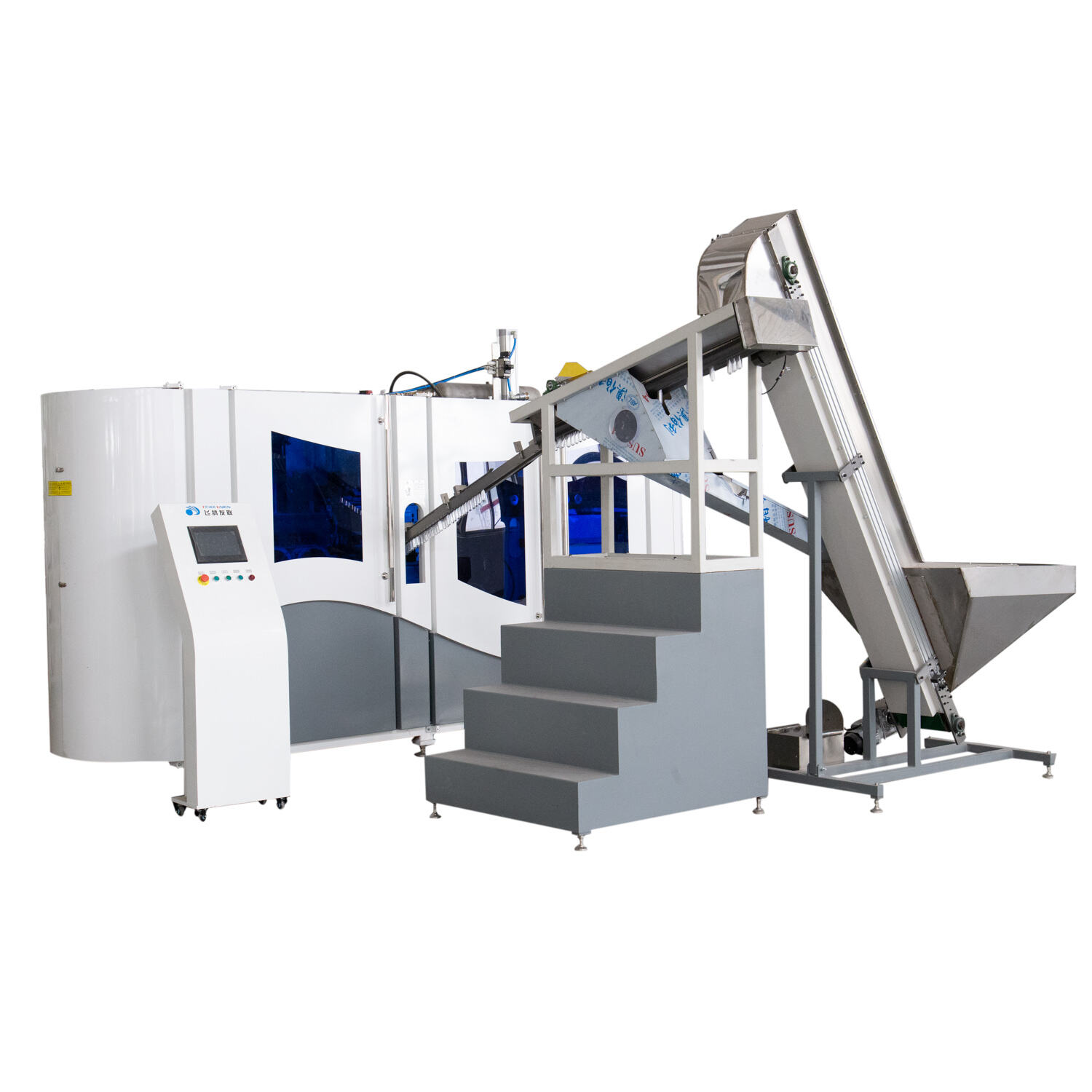

Hmm... vi siete mai chiesti come vengono realizzati i contenitori di plastica? Questi vengono realizzati tramite un tipo speciale di macchina chiamata macchina per stampaggio a soffiaggio. Questo straordinario pezzo è in grado di realizzare un certo numero di contenitori di plastica contemporaneamente, il che rende questa macchina un mezzo molto rapido. Un esempio di questo è la macchina per stampaggio a soffiaggio che produce contenitori da 20 litri per liquidi. E come tale è in grado di generare un numero elevato di contenitori visibilmente velocemente!

Si tratta di una macchina per stampaggio a soffiaggio ad alta velocità ed efficiente. L'azienda utilizza plastica calda per stampare i contenitori in diverse dimensioni. Questo è fondamentale, perché consente alle aziende di creare rapidamente molti contenitori. In questo modo possono risparmiare tempo e denaro, il che è ottimo per tutti. Le aziende che risparmiano tempo possono spedire più prodotti rapidamente, con conseguenti maggiori vendite.

La produzione di grandi contenitori di plastica è resa eccellente dalla macchina per stampaggio a soffiaggio di bottiglie di dimensioni maggiori da 20 litri. In genere immagazzinano liquidi come acqua o succo, cereali come riso e farina, altri prodotti alimentari sfusi (prodotti chimici, ecc.). A seconda della funzione che è programmata per svolgere, una macchina del genere può apparire in molte forme e dimensioni, ma sono tutte progettate anche con alcune caratteristiche comuni. Pertanto, è in grado di soddisfare varie peculiarità organizzative.

Questa macchina è nota soprattutto per la sua accuratezza. Può creare contenitori di forma e dimensioni identiche ogni volta. L'acqua è qualcosa che si diffonde con attenzione, come dovrebbe essere fatto un processo pianificato dalle macchine. Questa è la macchina di cui le aziende possono fidarsi quando si tratta di produrre contenitori di alta qualità in base ai loro requisiti e standard perché la responsabilità sociale inizia da dove ti trovi. La coerenza della produzione è fondamentale per le aziende e questa macchina le aiuta a mantenerla.

Sistemi meccanici e sensori sulla macchina che verifica che ogni lotto di contenitori costruiti sia realizzato correttamente ogni volta che viene eseguito. Di conseguenza, il processo di produzione è molto affidabile e ripetibile. Tempo, perché i lavoratori non devono più controllare fisicamente ogni contenitore e di conseguenza l'errore umano diminuisce. Ciò libera i dipendenti per completare altri lavori importanti per l'azienda.

Gli stampi utilizzati per dare forma al contenitore possono essere rotondi, quadrati o rettangolari e possono anche essere programmati in una macchina automatica. Essendo flessibili, le aziende possono scegliere la forma più adatta alla loro attività e al/ai loro prodotto/i. La macchina può anche realizzare contenitori speciali come contenitori con maniglia, coperchi e capsule. La versatilità di questa macchina è importante per le aziende che vogliono o hanno bisogno di diversità di produzione con tipi di contenitore perché può formare così tanti contenitori, configurazioni e usi.

Ancora più impressionante, la macchina può anche mescolare qualcosa chiamato additivi nella tua plastica. Questi additivi conferiscono ai contenitori una maggiore resistenza al calore, alla pressione e alla luce solare. I contenitori sono quindi in grado di contenere materiali diversi in campeggio senza essere violati. Rendendola una macchina ad alte prestazioni per produrre contenitori di alta qualità conformi a rigide linee guida.

I responsabili delle vendite sono attivi 24 ore su 7, 13 giorni su 20 per offrire il servizio più efficiente. Contattateci se avete domande sui prodotti. Faygo Plast detiene XNUMX brevetti nazionali, tra cui otto brevetti di invenzione. sono in continuo miglioramento XNUMX litri macchina per stampaggio a soffiaggioforniamo le ultime tecnologie ai nostri clienti. prodotti certificati ISO e CE. Certificati CE ISO

FAYGO UNION GROUP ha ora più di 500 clienti in diverse nazioni, tra cui Regno Unito, Spagna, Germania, Norvegia, Svizzera, Italia, Turchia, Russia ecc. Da Europa, America (Canada, Messico, Brasile, Venezuela, Chilly, ecc.) così come Arabia Saudita, Iran, Siria, India, 20 litri macchina per soffiaggio Indonesia così come Thailandia, India, Iran, Siria. La maggior parte dei clienti proviene dall'Africa e dall'Asia. La nostra fabbrica è situata nella città di Zhangjiagang e copre un'area di 26,650 metri quadrati. è a sole due ore di macchina dall'aeroporto internazionale di SHANGHAI.

FAYGO UNION GROUP ha 3 filiali. Una FAYGOBLOW che progetta e produce macchine per stampaggio a soffiaggio PET, PE ecc. FAYGOBLOW ha 5 brevetti che coprono invenzioni, otto brevetti per modelli di utilità. La macchina per stampaggio a soffiaggio PET FAYGO è la più veloce macchina per stampaggio a soffiaggio da 20 litri del suo genere al mondo. L'impianto di produzione della macchina per stampaggio a soffiaggio da 20 litri è FAYGOPLAST, che produce apparecchiature per estrusione di plastica, che includono linee di estrusione in plastica, linee di estrusione di profili in plastica. In particolare, FAYGOPLAST è in grado di fornire tubi in PE, PPR a velocità che possono raggiungere fino a 40 m/s.

Maggiore produzione (raddoppiata) Le rotative eseguono un funzionamento continuo anziché un funzionamento graduale e più fluido. Riducono il tasso di bottiglie difettose. Solo due scatole di riscaldamento, con la distanza di ogni testa dalla fonte di riscaldamento ridotta a 38.1 mm, il che può ridurre il 30% in più della macchina per stampaggio a soffiaggio da 20 litri rispetto al modello convenzionale, che è di circa 130000 kWh di energia elettrica, quindi un anno intero, basato su 8 ore al giorno, potrebbe ridurre di 20000 USD solo la potenza di riscaldamento. Oltre 100 paesi scelgono di essere partner e il mio team di assistenza post-vendita aziendale.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd Tutti i diritti riservati. Politica sulla Privacy