The Top 4 Suppliers of Plastic Pipe Production Line: Bringing Innovation and Safety to Your Pipes

Marketing important in any business continuing and it is especially important in the manufacturing industry where innovations, safety, and quality play critical roles in the growth of a company. One of the most important components of Feige Youlian Machinery manufacturing the production line, which responsible for producing goods, including plastic pipes, in an efficient, timely, and manner safe. We will introduce the top four plastic pipe production line suppliers and highlight their advantages, innovations, safety features, applications, and services.

Advantages of Using a Plastic Pipe Production Line

One of the primary advantages of using a plastic pipe production line it is more efficient and precise it enhances the production process, making. A Blow Molding Machine production line can produce mass quantities of high-quality plastic pipes in a shorter period unlike traditional manufacturing methods require a longer processing time. This leads to a reduction in labor costs and an increase in productivity. Additionally, the use of a plastic pipe production line also enables manufacturers to produce pipes with consistent size, shape, and thickness, which important for meeting the demands of the market.

Innovation in Plastic Pipe Production Line

Innovation the key to success for any business continuing and plastic pipe production line suppliers understand this principle. They have invested in modern technologies to design and produce production advanced are more efficient, accurate, and adaptable to meet the changing needs of the market. One of the latest innovations in this field the use of automation and robotics, which enhance the speed and accuracy of the PVC Profile Extrusion Machineproduction process while reducing human errors and safety improving.

Safety Features of Plastic Pipe Production Line

Safety a priority top any manufacturing process, and the production of plastic pipes no exception. Plastic pipe production line suppliers have implemented safety various to ensure workers are protected from the hazards may arise during production. These measures include safety sensors detect any anomalies in the machine's operations, warning alarms alert workers of potential safety hazards, and emergency stop buttons shut down the machine when necessary.

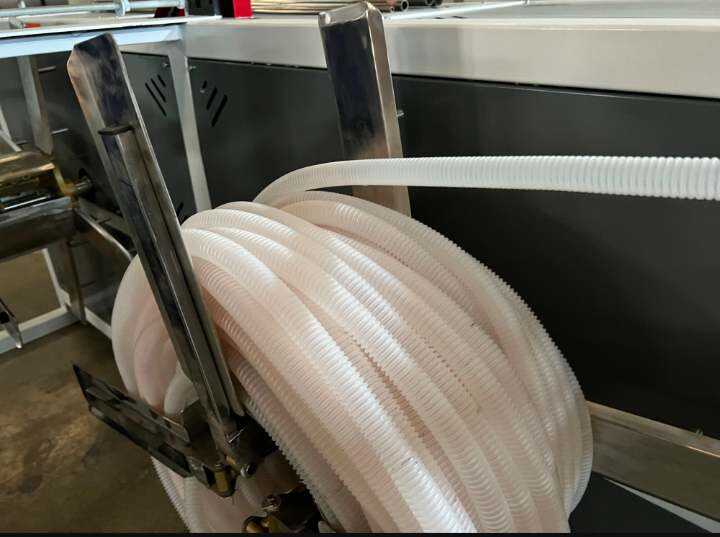

Applications and Use of Plastic Pipe Production Line

Plastic pipes are widely used in various applications, including irrigation, drainage, plumbing, and gas distribution. The Plastic Extruder Machine production line can produce different types of pipes, including PVC, PE, and PPR, which are suitable for different applications. Thus, plastic pipe production line suppliers cater to different industries, including construction, agriculture, and manufacturing, among others.

Quality and Service Provided by Plastic Pipe Production Line Suppliers

Quality an part integral of manufacturing process, and plastic pipe production line suppliers have a reputation for producing products are high-quality meet the industry's standards. They have invested in quality control measures, including inspection regular of machines, testing of the pipes produced, and certification from relevant bodies. Additionally, plastic pipe production line suppliers provide excellent customer service, including support technical maintenance, and training to ensure their clients get the best out of their production lines.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

PT

PT

RU

RU

ES

ES

IW

IW

VI

VI

TH

TH

TR

TR

UZ

UZ