Did you ever think, how plastic water tanks are manufactured? Allow me to show you one way, with a neat process called blow moulding. This method is incredibly invaluable because it permits the rapid production of water tanks and guarantees they are splendid fine. So, lets see how that part works in more details!

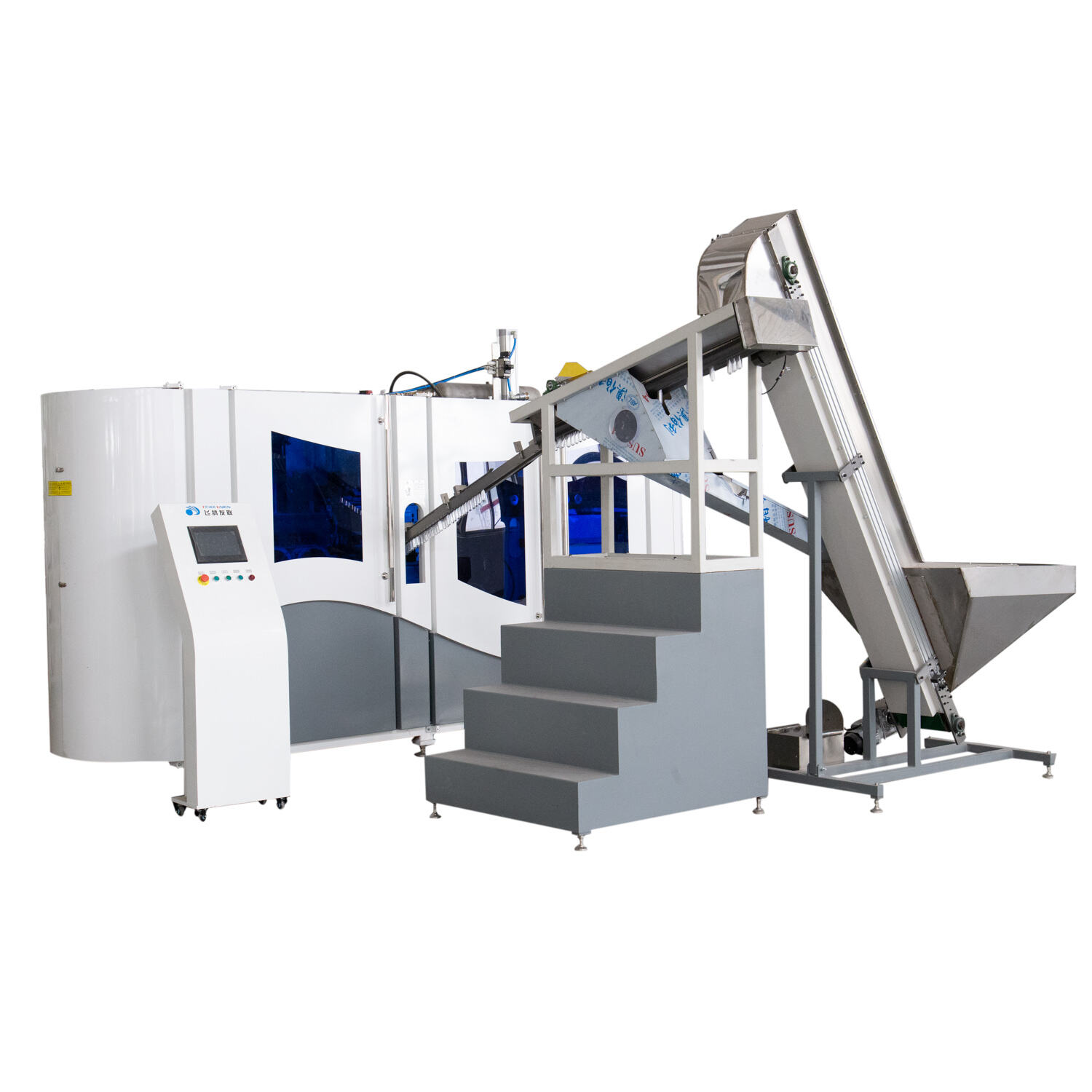

Molding is an important process that machines are used to produce plastic water tanks in different variety of shapes and size. These devices operate through the melting of plastic, and then molding it into a tank. The plastic when melted turns soft and can be poured into a mold easily. An experienced producer decide to use one of the best blow moulding machine that produce high quality and tough water tank which able filled with a lot amount of water without easily broken.

Blow moulding is quite interesting, relatively speaking and it could mean huge savings in the production costs of plastic water tanks. There it is a very clever way, because you can build many tanks using just one machine. This makes the price of production of each tank lower, which is excellent for businesses. What is more, machine blow moulding requires less man power to handle the machines too; therefore it helps save extra labour costs as a complete. This results in a plastic water tank that is typically less expensive for the manufacturer to produce, and which can then be sold cheaper than other storage options such as concrete tanks - ultimately making them significantly more affordable for home owners or business.

Blow Molding Machines Are Also Unbelievably Versatile Another great thing about these blow moulding machines is that they are incredibly versatile. Water tanks can be constructed in these companies according to various size and shape requirements. The machine can readily alter the contour and size of this tank - in brief, there are select for its shoppers. In this, they have the right to get a suitable water tank for their space availability and storage needs. Whether someone requires a small tank for their garden or something that fits in the corner of your room, blow molding can address those needs.

One of the best ways to utilize strong and safe water tanks is anything but other than blow moulding as making plastic water tanks using this process. The process results in a uniform piece of plastic with no seams or joints that might deteriorate over time. This ensures that the tanks do not leak and are functional for water to be held. One of them is its well-known hardness and longevity are constructed from a specific sort of stuff named high-density polyethylene. This indicates that the tanks are resilient to different climate conditions and last for many years.

FAYGO UNION GROUP has 3 branches factories. One FAYGOBLOW which design make blow molding machines make PET, PE etc. FAYGOBLOW the owner of five patents related inventions and 8 patents in utilitarian models. FAYGO PET blow molder is plastic water tank blow moulding machine and most efficient design in world. second manufacturing facility is FAYGOPLAST which manufactures plastic extrusion equipment. includes the plastic pipe extruding line and extruding line for plastic profile. Particularly, FAYGOPLAST can provide PPR, PE pipes at speeds that can reach up to 40m/s.

increase output(doubled) Rotary perform uploading a soft and continuous manner. perform continuous running instead step by step and movement is more gentle. Reduce number faulty bottles. fitted with two heating box, each heating head distance minimized 38.1mm, which can reduce 30% more electricity than the plastic water tank blow moulding machinemodel, which is about 130000kwh electrical power, which means one year based on 8 hours a day, you could save you 20000USD only on heating power; Over 100 countries choose to be partners as well as my own after-service team.

Service online: sale managers are available 24/7 give customers most quick answers. invite you to contact us have any plastic water tank blow moulding machineabout our products. Patents certificates: Faygo Plast has 13 national patents, including eight invention patents. keep improving our products and are able to provide the most recent technology our customers. product have CE and ISO certification.

FAYGO UNION GROUP now more than 500 customers spread across countries like UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. From Europe, America (Canada, Mexico, Brazil Venezuela, Chilly, etc.) and Saudi Arabia, Iran Syria, India, Thailand Indonesia Thailand Indonesia. Many customers coming from Africa as well as Asia. Our factory, which is located in Zhangjiagang City, has an area of 26650 square plastic water tank blow moulding machine. only takes around two hours driving to SHANGHAI International Airport.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy