Industrial plastic pipe production line I.pipe with heat cutting, Treating Pipes II. Planetary Cutting System III. Pipe Breaking Machine IV. Vacuum Suction Vs.Cooling Tank

A plastic pipe extrusion machine is actually among the most vital product usage in all around the earth to create a myriad contingency tubes and diameters. These machines are used to create PVC pipes of different sizes and designs in the factories itself. Hence, in this article we will introduce you to the top 5 patterns of plastic pipe extrusion machine which can be widely witnessed throughout various industrial applications.

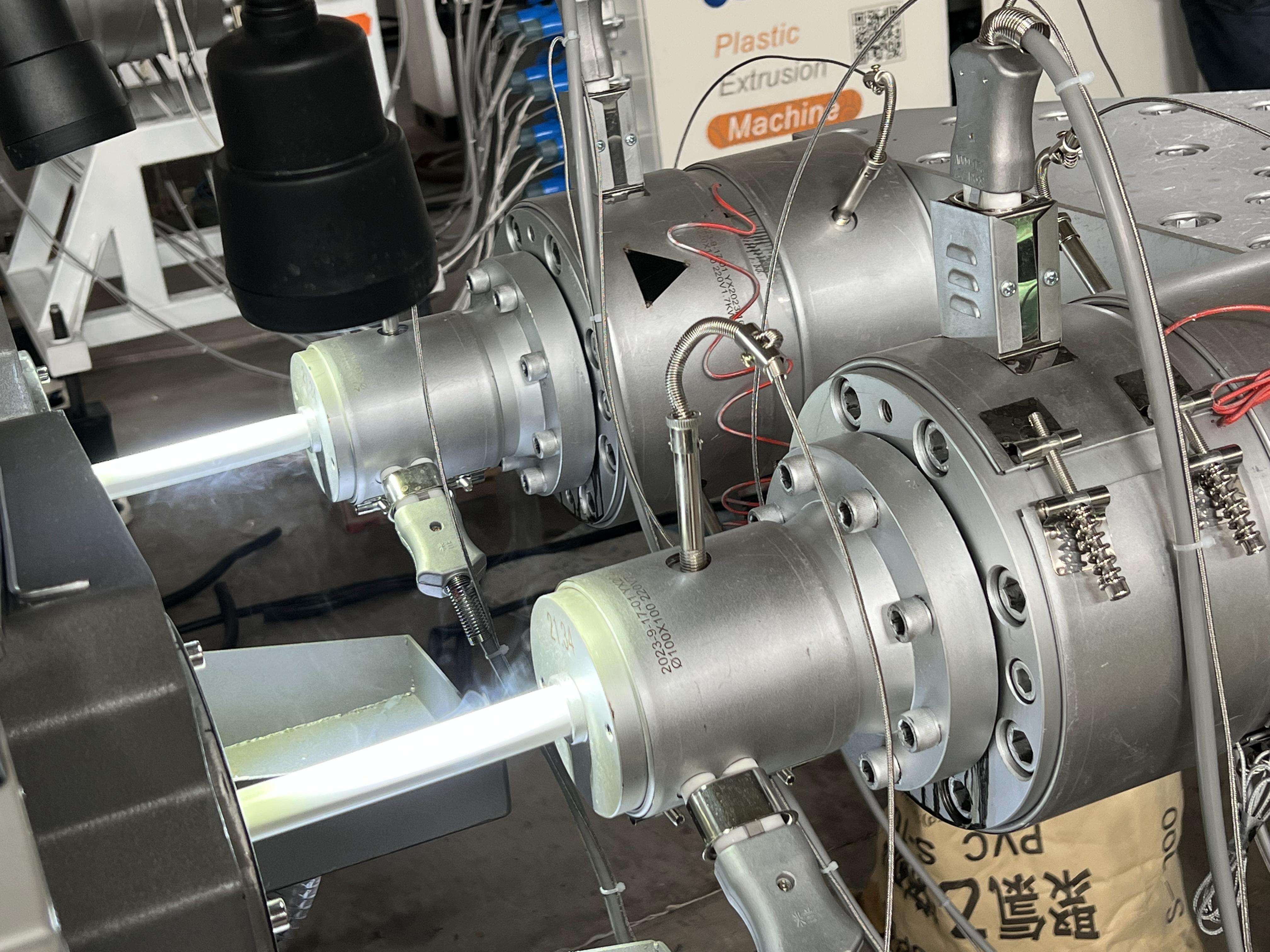

Twin Screw Extruder : The twin screw extruders are the best of PVC pipe making machines that allows you to get one stop solutions for all your needs It performs a parallel and continuous process of extrusion with the help of two screws. Additionally, this machine features advanced automation which makes it easy to use and maintenance-free too.

Single Screw Extruder : a single screw extruders can also be utilized in the production of PVC, PE and PP pipes although it is relatively easier to operate. Long Line of ExtrudersF Concatenate ( Single Sentence )Extrudef}); In case, to cater a specific requirement in different dimensions and cross-sectionspipes can be made through these machines.

The screw and barrel combination in the planetary extruder allows very efficient as well a constant production of HDPE pipe. These features are designed primarily to make this COP very simple and easy-to-use, thus it is of great importance in the industrial setting where ease-of-operation or maintenance plays a critical role.

Conical Twin Screw Extruder - This particular conical twin screw extruder has been designed specifically for making the PVC pipes manufactured supported by a set of co-rotating & intermeshing screws ensuring homogeneous product quality in parallel. In simple terms, it is also the fact of other advanced automation features in that you use sensors and temperature controls were to improve accuracy.

Co-extrusion Pipe Extruding machines:-This machine is used with multi-layered pipes to make core and outer pipe layers. It is the best choice for industrial pipe production needs that comes with a number of high tech automation functionality, making it easy to operate and maintain.

There are also many other features found in these plastic pipe extrusion machines that makes the manufacturing process easier writelargepipe Key Machine Features

Few of them are as follows: Automatic Control, Material Handling & Temperature Regulation - This comes in the top category (Automatic Type) which has automated features installed with it like automatic control, temperature regulation and material handling.

Anything would be fine when it is in the base plastic form or even after being chemically added to as no residue will affect their outputs - hence modern plant's high quality products.

Variety: One of the biggest advantages to using these machines is that they are capable of producing pipes in a wide range of sizes, shapes and materials. This range comprises pipes to PVC, PP and PE...and in addition they service large volumes of multidomesticpipe pro- duction.

The model is always associated with a very user centric, easily controlled interface: natively supported on touch screen panel that would display all important information.

Easy to Maintain -The simplicity of these machines means that they are easy to fix and keep running, should their need arise. If the machines fail, this can be resourced in a very short time so that further production processes do not have to stop.

The first reason of The Necessity for Plastic Pipe Extrusion Machines in factory production lines: In the factories and workplace areas, expressing any kind of product from plastic is done with a lot more ease than using other materials. In this article, we will read 5 most essential points why they are:-

Increased Efficiency: Normal and continuous extrusion process can enhance the productivity of various plastic pipe production lines, which will drive up brand efficiency and slow down lead times for when products actually hit shelves.

Excllent practical experience: powers that be the top of your collection pipe to face up below a few situation which includes high pressure and temperature therefore causing them efficient for professional use.

Cost-Effectiveness of Plastic Pipe Extrusion Machines: This type of machines offers a cost-effective way to produce pipes, cutting the production price in half compared with standard manufacturing methods and translating this into lower operating costs

Extensive Usage: From construction to agriculture up to plumbing, these machines are in demand and efficient across various sectors as they can cater the production of tubes ranging from different sizes and forms.

Eco-friendly: plastic pipe extrusion machines are produced using state of the art technology that do not harm the environment in any way, as these plants consume recycled materials in order to get their final products (i.e. pipes), thus creating a more sustainable system and contributing for waste reduction campaigns along with preserving natural resources; providing an eco-friendlier alternative trend against traditional options available on other suturing solutions.

This beginners guide is intended for aspiring plastic pipe extruding machine operators.

Machine Installation: For all installation follow the manufacturers guidelines to properly install your machine, this includes connecting too power source and lubricating checking for any other issues.

Preparation Of The Material: Begin to feed the material and make sure that it is not impure so are we receive product quality.

Only after making all the connections, then set heating elements on certain levels in machine as this is heated up tp its melting point and pulling becomes smoother which was a very vital role in anu type of extrusion process.

Extrusion Process: Material is fed into the extruder barrel, where it melts and then molten form of screw pushed through a die.

Cooling: After extrusion use a cooling mechanism which can cool the pipe and make it harden for its enduring purpose.

You can use a cutter to cut that pipe using your cutting machine when it would be properly cool down according to the desirable size.

A number of plastic pipe extrusion machines prove to be quite useful in boosting productivity with their special features. How these systems work to be time and cost-efficient:

Consistency in Quality Pipe Production: The uniform extrusion process of this unit delivers a great number of high quality pipes at the production line, making sure to give you with consistent and accurate results on every single output.

Production time is reduced: The outstanding efficiency of plastic pipe extrusion machines leads to faster production times, which means that operators can produce more units in less tim.

Easy User Interface: They are easy to use and does not require human input minimize production time.

Since the machines are flexible enough to produce pipes in any sizes, shapes and name it as per different sectors requirements is a proof how versatile these assets can be which enables them cater wide varieties of applications.

Reduced Labor Costs: Although needing a small human factor, plastic pipe extruding machines have the lower labor costs that churn in more profits and low operations cost at manufacturing plants of pipes.

To recap, how a plastic pipe extrusion machine works makes it an invaluable asset for production plants which produce this sort of product often with even more specifications than have been discussed in detail today but these functions provide efficient speedy and cost-effective eco-friendly processes. These do not only increased production with their quick and consistent material but highly functional to serve numerous industrial necessity so that they could get used in the early stages for several lines of industris.

FAYGO UNION GROUP now has over 500 customers in different nations, including UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. from Europe America, Canada, Mexico, Brazil, Venezuela, Chilly, etc. from America Saudi Arabia, Iran, Syria, India, Thailand, Indonesia etc. from Asia well as a large number plastic pipe extrusion machinefrom Africa. factory located in Zhangjiagang city. It covers an area of 26,650 square meters. It's only two hours drive SHANGHAI international airport.

FAYGO UNION GROUP made from 3 branches. One is FAYGOBLOW that designs manufactures blow molding machine PET, PE etc. FAYGOBLOW has five patents invention, 8 patents utility models. FAYGO PET blow molding machine is among the most efficient fastest designs plastic pipe extrusion machinethe globe. second factory FAYGOPLAST which produces extrusion machines made of plastic, such as plastic pipe extruding line, plastic profile extruding line. Particularly, FAYGOPLAST is able to supply the highest speed of up to 40m/min PE PPR pipe line.

Sales managers online 24 hours day provide the most rapid service. you have any questions about products or services, please contact . Patents and Certificates: Faygo Plast has 13 national patents. Among them are 8 invention patents. constantly improve our products to plastic pipe extrusion machinelatest technologies to our customers. Our products have CE ISO certifications

Increased output(doubled) Rotary perform uploading, soft continuous, run continuous, instead of step-by-step moving more smoothly. Reduce number bad bottles. Only two heating box, each one's heating head's distance reduced to 38.1mm, which can reduce 30% electric than the standard one, which plastic pipe extrusion machine130000kwh electric power, so year based around 8 hours per day, can save 20000USD only heating power. Over 100 nations choose us as partners as well as my own after service team.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy policy