The pipe extrusion machines are essential equipment suppliers to the pipe manufacturing industry, especially in industrial applications. A vast range of top-grade plastic pipes are produced with different sizes and shapes by these machines, that too within no time. Pipe extrusion machines are very functional when it comes to industrial production, and there a lot of benefits that manufacturers could get out from using them.

Using a pipe extrusion machine in industrial manufacturing can bring one significant benefit, which is highly enhanced efficiency. These machines are designed to manufacture pipers very quickly as compared to the traditional methods of manufacturing. Manufacturers can therefore meet production requirements more promptly as a result, fostering greater profitability and competitiveness in the market.

Moreover, pipes produced with pipe extrusion machines are known to be consistent in size and shape which is an essential characteristic of industrial manufacturing. Nonetheless, it is necessary that their size and type conform to the standards in order for them to reliably withstand high pressures under challenging environmental conditions. Using a pipe extrusion machine, you can ensure that every single pipe produced is consistent in terms of its shape and quality, this allowing these pipes to be applied confidently within various industrial fields or environments.

Applications of pipe extrusion machines; Types of Pipes Produced by Pipe Extrusion Machines

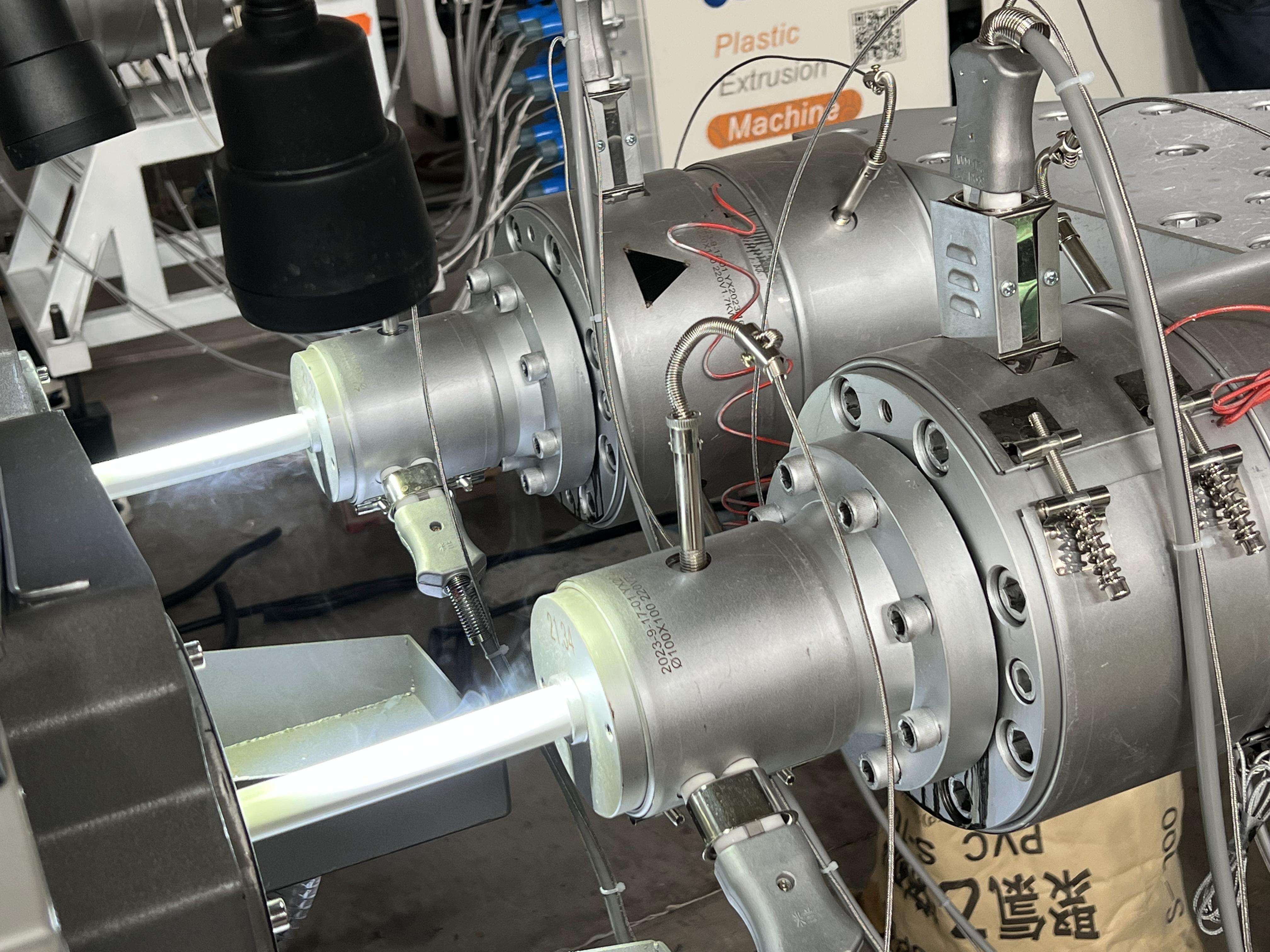

Pipe extrusion machines have the ability to manufacture a variety of pipes developed in line with certain workplace needs. Polyvinyl chloride (PVC) pipes make a popular type of pipe because they can be manufactured using these machines. Because of their chemical resistance, durability and ease of installation they are used in applications such as plumbing, irrigation & drainage systems.

Some other type of pipes these used along with PVC are the HDPE-pipes made by pipe extrusion machines. They are used in gas distribution, water pipes and sewage systems with advantages like strength, flexbility and durability. Being able to handle pressure and mobility makes them perfect fora industrial application.

Besides, pipe extrusion machines can be used for production of other types of pipes such as polyethylene PEX or PP-linier tubes and PB type tubes. The choice of pipe type that works with any project also constitutes a versatility and customization factor available through these machines to consider.

First, attention should be paid to properties necessary for a pipe extrusion machine when buying one in order facilitate its proper functioning. In determining the other critical feature to look out for, we consider its capacity which means how much piping it can fabricate in a given time interval. Businesses that need toproduce a large volume can choose something with a higher capacity of machines which is best for their system.

Another important aspect to check is the extrusion speed of pipe making machine that shows how fast it can manufacture pipes. Increasingly prevalent in today industry to find machines with rapid extrusion which gives the manufacturer a chance to improve their yields. Secondly, the potential compatibility of the machine with a broad variety of materials shows that it will be extremely versatile and may be readily applicable in several manufacturing environments.

Also the pipe extrusion machine is to be easy to maintain and operate so as well a crucial point when selecting one. When it comes to coursework, manufacturers prefer simpler machines that can be operated by anyone and require minimal maintenance to keep running smoothly for longer periods of time.

Taking care of pipe extrusion machine is crucial as it helps to enhance its longevity and efficiency. The machine will be well-lubricated to support the functionality that it is intended for- particularly important with machinery of this size, so as not to cause friction and damage.

You will also need to clean the machine on a daily basis so that there is no debris or dirt build-up during manufacture and therefore performs consistently each time fast skin pack. Psst: Be sure to avoid any overheating of the machine as this could permanently damage its parts and thus stop it working correctly.

In addition, the machine components have to be checked on a regular basis so that any impending problems can be diagnosed and resolved prior they getting out of hand causing breakdowns or higher repairs. However, pipe manufacturers can extend the life and resolution of their extrusion equipment by undergoing regular maintenance.

It is imperative that industrial manufacturers perfect their operational processes by enhancing production efficiency - and a pipe extrusion machine has plays an important role in this matter. Opt for a machine that suits the industrial application selected and maintaining production capacity & extrusion speed to amplify efficiency and output.

Keeping the machine within its optimal operating temperature as well observing it perform on a regular basis play and integral part in efficiency improvements. With early detection and troubleshooting of potential problems manufacturers can avoid operational disruptions which could interfere with their production flow.

Another measure that you can take to enhance the productivity of production is investing in extensive employee training. You can use this machine efficiently on the working ground and with their high- skilled staff to operate it, downtime would be minimized which in return increases overall productivity. These were some of the strategies which if employed, would help industrial manufacturers leverage a pipe extrusion machine to meet their production demands effectively and will also keep them competitive in market.

Pipe extrusion machines are indispensable to any industrial manufacturing process through which high-quality pipes for various applications can be produced. By choosing the right machine to use and stick with operating it properly each time, manufacturers can improve their efficiency that will result in better productivity which eventually translates to increasing profitability. Done correctly, all of these suggestions will allow industrial companies to install pipe extrusion machinery and function in order to satisfy the requirements from the sector as well as keep a aggressive benefit_EMITPIPE.

Now FAYGO UNION GROUP has more than 500 customers across different countries including UK, Spain, Germany, Norway, Switzerland, Italy, Turkey Russia etc. From Europe ,America, Canada, Mexico, Brazil, pipe extrusion machine, Chilly etc from America, Saudi Arabia, Iran, Syria, India, Thailand, Indonesia etc. from Asia, and many customers from Africa. factory, situated Zhangjiagang City, has an surface of 26650 square metres. From the airport, factory only two hours.

Sales managers e 24/7 to offer the most efficient service. Contact if you have any questions regarding products. Faygo Plast holds 13 national patents, including eight invention patents. are always improving pipe extrusion machineprovide the latest technology to our customers. products certified by ISO and CE. CE ISO certificates

FAYGO UNION GROUP has 3 branch factories. One FAYGOBLOW that designs manufactures blow molding machine PET, PE etc. FAYGOBLOW has 5 patents invention, as well as 8 patents for utility models. FAYGO PET blow moulder is the fastest and most efficient design available the pipe extrusion machine. second manufacturing facility is FAYGOPLAST, which make plastic extrusion machinery, including the plastic pipe extruding line and extruding line made of plastic profile. Particularly, FAYGOPLAST provides high speed up to 40 m/min PE, PPR pipe line.

Increased output(doubled) Rotary perform uploading Soft continuous, pipe extrusion machinecontinuous running, instead of step-by-step and movement that \more gentle. Reduce Bad Bottle Rate. Only equipped with two heating boxes, each one's heating head's distance is reduced to 38.1mm and can save 30% electric than the conventional model, which \about 130000 kwh of electric power. So, for a year that is based \eight hours per day, can reduce 20000USD only on heating power; More than 100+ countries have us as partners my company after service team.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy