NextGen of PET Packaging with Stretch Blow Moulding Machines

PET stretch blow moulding machines are one of the most crucial equipment in PET packaging industry that offer precision performance for high-speed output from quality bottle production. These savvy machines are a new standard in the industry for any producers that want to stay up with what is required by their market.

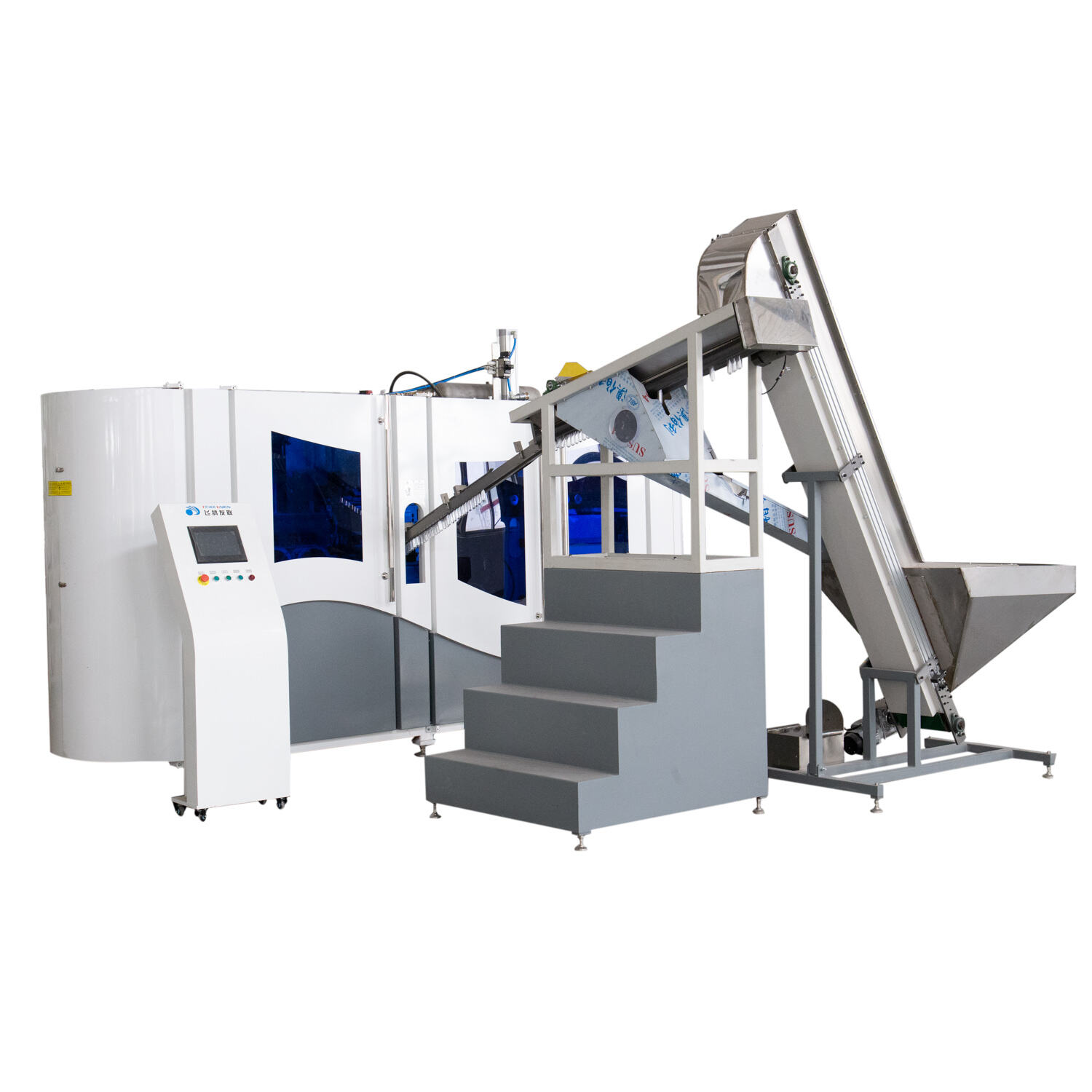

The stretch blowmolding machineis a modern machinery utilized to manufacture pet bottles from plastic preform. The donut shaped plastic preforms are capable of being melted down and then stretched to become a bottle. It includes heating unit for melting the preform and blow moulding system to make bottles.

This is why it has been claimed these days that pet stretch blow moulding machines are best manufactured for huge production bulk orders at very ease of the producibilities. These machines are technologically advanced and built with an overload of features to include automatic prefom loading & unloading, along with a facility for carrying on in-line filling as well as capping so that the companies can produce high quality bottles at quickly without any shortage due to customer demands production.

As an added benefit, the machines are reliable and do not experience breakdowns that cause a halt in production. By the way, in contemporary systems (like through a good purpose-built monitoring solution), could by alerted to faults or errors long before they became production risks and issues.

Usage of pet stretch blow moulding machines allows manufacturers to increase productivity and thus results in improved profits & margins. These machines are not only energy efficient (taking less power compared to traditional manufacturing) but they also cut demand with lower prices in reference to the supply of production. This new way of doing it is what manufacturers do now and saves them cost, in part because energy efficiency.

In addition, the use of pet stretch blow moulding machines can greatly reduce waste by allowing for reuse and transformation of any additional plastic residue that builds up during manufacturing. It is an eco-friendly practice that reduces the carbon footmark on nature by the company.

Stretch blow moulding machines, on the other hand have brought a revolution in pet bottle manufacturing as those stretch machine allows manufacturers to produce quality bottles at lower cost. Machines with this technology supply variety of additional features which cut back the timing of production most economically.

In addition to, PET stretch blow moulding machines gives even quality in bottle is also of the uniformity - shape and size as well as thickness. This quality control element makes sure that the bottles will not only look good, but can also adhere to safety standards for consumer use.

The advent of pet stretch blow moulding machines has actually revolutionized the way in which manufacturers package their products, providing them with an efficient and affordable method for producing top-of-the-line containers. This increases the speed of production, removes waste and is eco-friendlier as well. Without a doubt, the pet stretch blow moulding machines are one of those essential equipment which now turns out to be indispensable for all minor and major day-to-day things...Yes.... the PET bottle with expected demand increase for future years.

FAYGO UNION GROUP now has over 500 customers in different nations, including UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. from Europe America, Canada, Mexico, Brazil, Venezuela, Chilly, etc. from America Saudi Arabia, Iran, Syria, India, Thailand, Indonesia etc. from Asia well as a large number pet stretch blow moulding machinefrom Africa. factory located in Zhangjiagang city. It covers an area of 26,650 square meters. It's only two hours drive SHANGHAI international airport.

Increased output(doubled) Rotary perform uploading, soft continuous, preform continuous running, instead step-by-step with more smooth and soft pet stretch blow moulding machine. Reduce Bad Bottle Rate. Reduce number of bad bottles.

FAYGO UNION GROUP made from 3 pet stretch blow moulding machine. FAYGOBLOW a blow molding machine manufacturer PET, PE other materials. FAYGOBLOW has 5 patents covering inventions, eight patents utility models. FAYGO PET blow molding machine among fastest and most energy-efficient design worldwide. second manufacturing facility is FAYGOPLAST, which make plastic extrusion equipment. This includes the plastic pipe extruding line and extruding line for plastic profile. Particularly, FAYGOPLAST is able provide PPR, PE pipes at speeds that can reach that can reach 40m/s.

sales representatives all hours of the day to provide fastest possible service. invite you contact us if have any queries about products. Patents and certification: Faygo Plast has 13 national patents. Among them are 8 invention patents. We are always pet stretch blow moulding machineour products provide the latest technologies our customers. products have CE ISO certificates

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy