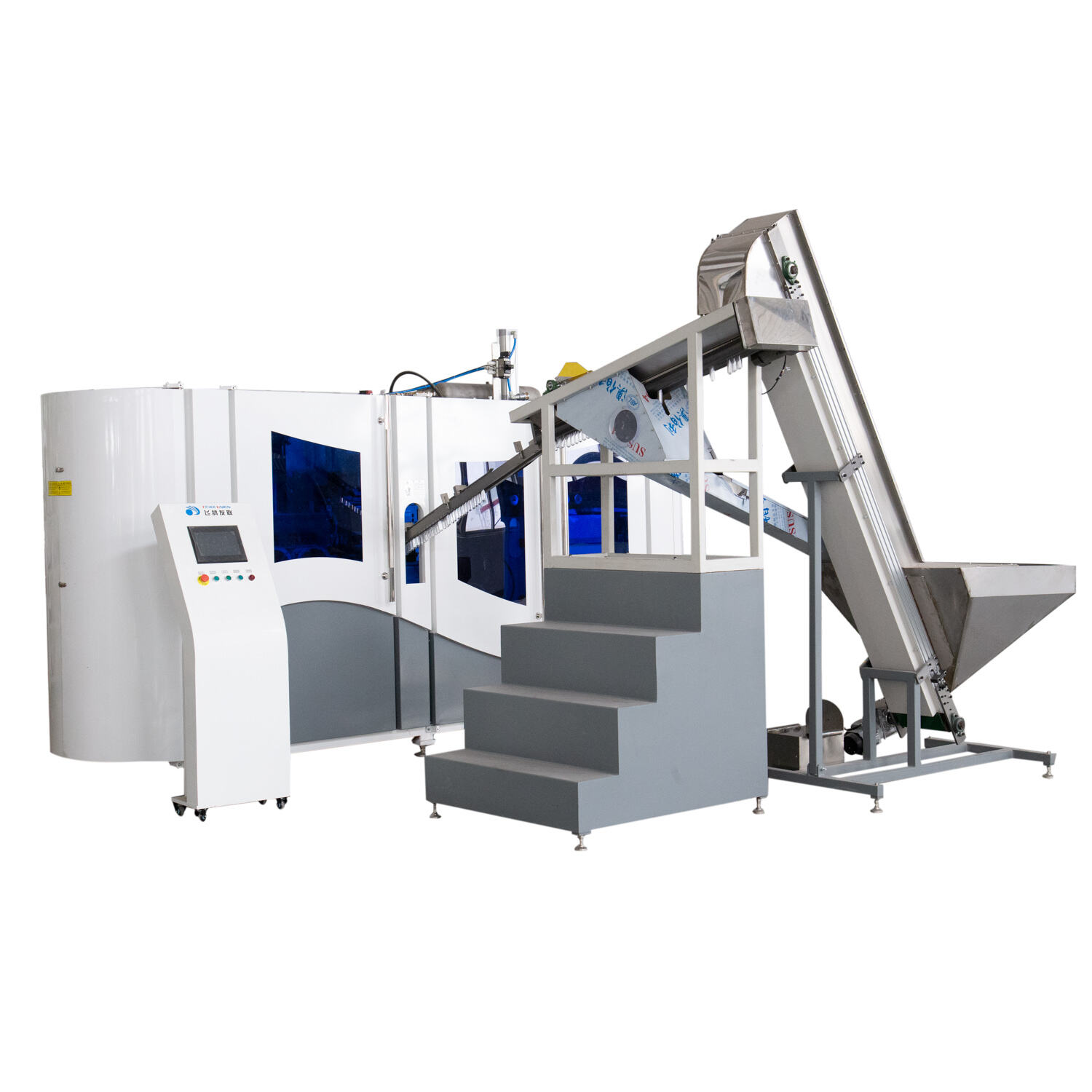

The Pet Bottle Making Machine is an incredible invention that works in the manufacture of plastic bottles. It is often referred to as some magical box that turns small plastic into big ones! In our new exciting series, we will take a deep dive into the guts of this fictional creation and how it has revolutionized manufacturing for many companies as well as what such results should mean to enhance efficacy ultimately within production.

The Pet Bottle Making Machine has been no less than an incredible ride. Bottles used to be made by hand, an arduous process. But, now because of the technological development that machine has grown. Nowadays, this custom device is able to produce multiple thousands of bottles per day.

The way this works is that a bunch of these tiny plastic chips are taken, melted all up so they become more goey and then blown into the mold to make your one big bottlegy! The name of this enchanting process is blow molding.

Ways Pet Bottle Making Machine Changing Manufacturing Industry

Enjoy Delivering Pet Bottle Making Machine: The Era when Bottles Production was so hard... But not to make bottles are quick, easy and secure process with the help of this machine. This innovation has brought a revival throughout the industries, enabling businesses to scale up their production through every possible procedure.

Along with this, it is entirely Eco-friendly to Great degree through Pet Bottle Making Machine. These are the benefits of using pet made bottles An excellent durability Lighter to the handling and transport Then pet will not be shattering or breaking as well, so that it is possible for them being packed and stashed wherever. Additionally, they are eco-friendly and recyclable.

Companies can use Pet Bottle Making Machine for quick bottle manufacturing. This also fastens the process of production leading to improved sales and profit in business. Additionally, the machine is highly user-centric making it automatic control ( if in case plastic pieces are set properly and hence no manual attention required) adding up to not only just a speed but also aiding impressive straightforward production.

The broad utility is the fundamental element that conserves your effort and time by employing P-E-T Bottle Making Machine. This mini sandblasting set is beneficial in several settings. Companies use it to make bottles of all sorts, for water, soda and juice or whatever.

It also comes loaded with various customizability options The size, shape and color of the bottle could be custom-designed by a business This meant businesses could build bottles that perfectly matched their branding.

Now are the days of 100 miles per hour five-second left times, and accordingly we need to be fast. So, the presence of PET Bottle Making Machine is this way to fulfill above stated requisites within short moment. As a country that aspires sustainability, this device is an excellent invention suitable for time period we have entered because of its environmentally sound properties.

From small end to large corporations, across the globe this machine have enabled people everywhere. Business becomes very easy thanks to Pet Bottle Making Machine Production with superior productivity.

So, in the conclusion feather we can say Pet Bottle Making Machine is a new era invention by technologists for production. Besides increasing manufacturing, productivity it also forces a lot of environmental sustainability to them. This makes it so that companies are able to push products through a much quicker lead time, offering clients something totally different and personalised.

FAYGO UNION GROUP made up of 3 branches. FAYGOBLOW is blow molding machine producer for PET, PE other materials. FAYGOBLOW is owner of five patents invention and 8 patents utility models. FAYGO PET blow molder is fastest most effective pet bottle blow moulding machineits kind in the world. second manufacturing facility is FAYGOPLAST. makes plastic extrusion machines for example, extruding lines made of plastic pipe, and extruding plastic profiles. Particularly, FAYGOPLAST can offer PPR and PE pipes at speeds up to 40m/s.

Service online: sale managers are available 24/7 give customers most quick answers. invite you to contact us have any pet bottle blow moulding machineabout our products. Patents certificates: Faygo Plast has 13 national patents, including eight invention patents. keep improving our products and are able to provide the most recent technology our customers. product have CE and ISO certification.

Increased output(doubled) Rotary perform uploading Soft continuous, pet bottle blow moulding machinecontinuous running, instead of step-by-step and movement that \more gentle. Reduce Bad Bottle Rate. Only equipped with two heating boxes, each one's heating head's distance is reduced to 38.1mm and can save 30% electric than the conventional model, which \about 130000 kwh of electric power. So, for a year that is based \eight hours per day, can reduce 20000USD only on heating power; More than 100+ countries have us as partners my company after service team.

FAYGO UNION GROUP now has over 500 customers different countries, including UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. Europe ,and America, Canada, Mexico, Brazil, Venezuela, Chilly etc from America as well as Saudi Arabia, Iran, Syria, India, Thailand, pet bottle blow moulding machineetc. from Asia a lot clients from Africa. Our factory situated Zhangjiagang city, which covers an area of 26,650 square metres. distance from airport to factory is just two hours.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy