Did you ever ponder on how plastic stuff such as bottles, jars or containers are produced? It’s really interesting! Blow moulding is the term used for one of these common methods. A process that is special to mould plastic products into various shapes So how can we do so now and for the even better use of a machine known as fully automatic blow moulding machine!

It goes way back to before this amazing machine was invented, making plastic products used a lot of steps and hard work. Because the workers needed to get some raw materials, which are essentially just ingredients when it comes integral manufacturing needs this material melted down and then shaped into it form before letting i cool. It was a laborious process that had to be conducted in tandem by many people. However, the fully automatic blow moulding machine does all these in a single convenient process simplifying everything.

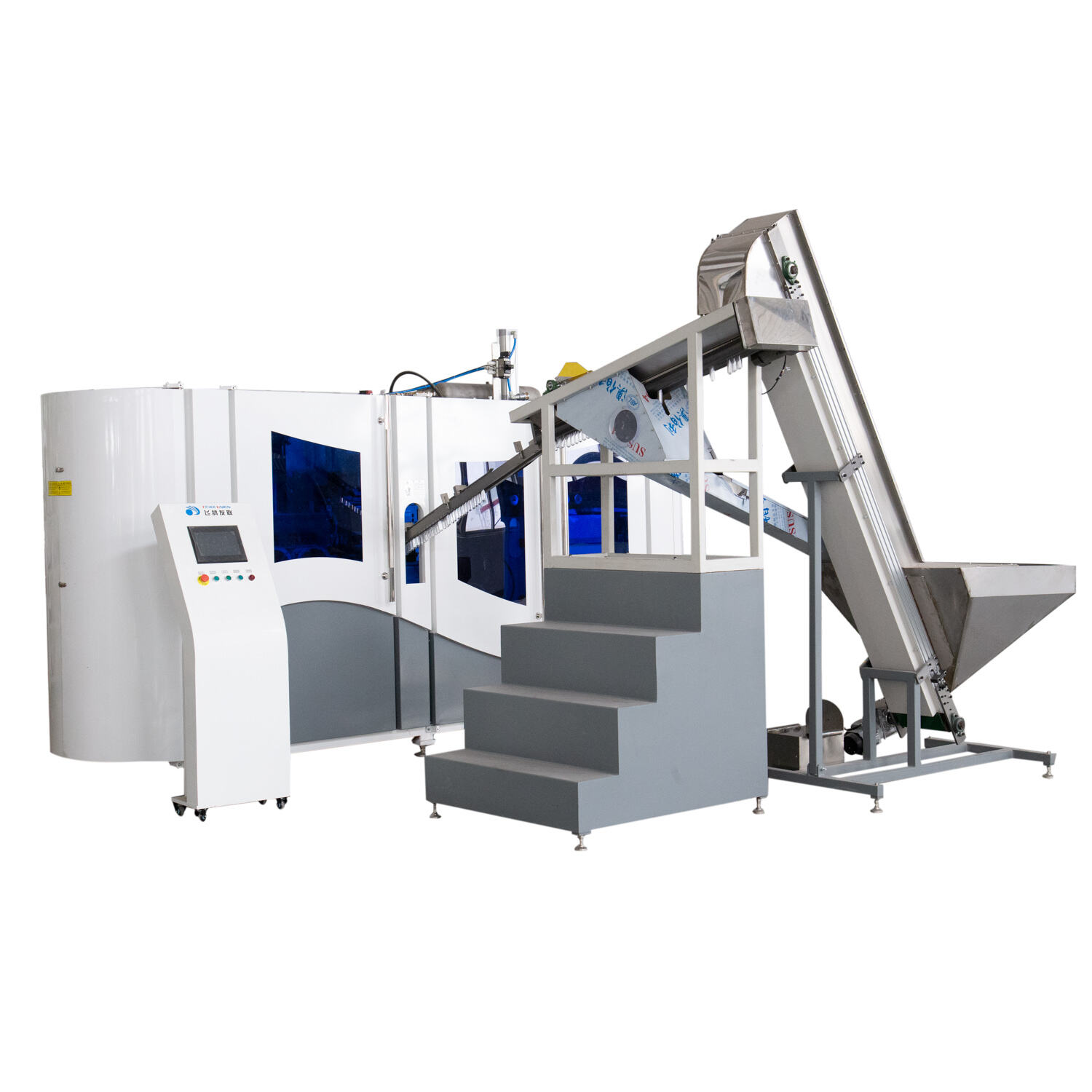

This marvellous device turns pure plastic into liquid, then inflates it to give us the desired form. And it does this all by itself, no people required! One of the key reasons for this is that it enables factories to produce many more plastic products than wasever possible before. It will help in saving time and it meet the requirement of multiple customers who are willing to buy those products.

There are a lot of pros to this machine. To start with, it of course works great and is super efficient. It can produce countless plastic items in a very short period of time, which is great for manufacturers as they make more and earn money. This is crucial because businesses are structured to keep their customers satisfied and they aim towards profits as well.

Ease of use: this is the second but among all, it have a very simple UI. Workers simply have to say the shape, size of what they want from it and machine does rest. That way, you can reduce the risk of committing mistakes during production and also in order to perform repetitive work easily.). Manufacturing requires uniformity; each bottle or container must be the same in order for proper function and assembly.

The other important point is that, because the products are made in standardized form to ensure they fit together as intended; factories can become known for their reputation of producing high-quality goods. This can mean more customers and revenue. If a factory regularly delivers good results, then people will begin to lean towards their products.

B- Awesome machineSecond, it is a very reliable machine. This results in less number of corrections and fixing things later reduces by manufacturing high-quality products. This is an important factor for factories as time over long term and breaks etc are all avoided, this fact proves the importance of reliability.

Increased output(doubled) Rotary perform uploading, soft continuous, run continuous, instead of step-by-step moving more smoothly. Reduce number bad bottles. Only two heating box, each one's heating head's distance reduced to 38.1mm, which can reduce 30% electric than the standard one, which fully automatic blow moulding machine130000kwh electric power, so year based around 8 hours per day, can save 20000USD only heating power. Over 100 nations choose us as partners as well as my own after service team.

moment now FAYGO UNION GROUP has more than 500 customers from various countries including UK, Spain, Germany, Norway, Switzerland, Italy, Turkey Russia etc. from Europe and America, Canada, Mexico, Brazil, Venezuela, fully automatic blow moulding machineetc from America as well Saudi Arabia, Iran, Syria, India, Thailand, Indonesia etc. majority of customers from Africa as well as Asia. factory, situated in Zhangjiagang City, has a total surface of 26650 square meters. From airport, factory is only two hours.

Sales managers online 24 hours day provide the most rapid service. you have any questions about products or services, please contact . Patents and Certificates: Faygo Plast has 13 national patents. Among them are 8 invention patents. constantly improve our products to fully automatic blow moulding machinelatest technologies to our customers. Our products have CE ISO certifications

FAYGO UNION GROUP has 3 branches factories. One FAYGOBLOW which designs produces blow molding machine PET, PE etc. FAYGOBLOW has 5 patents covering inventions, eight patents for utility models. FAYGO PET blow molder is quickest most fully automatic blow moulding machinedesign of its kind in world. fully automatic blow moulding machinemanufacturing facility is FAYGOPLAST, which make plastic extrusion equipment, which includes extruding lines made plastic, plastic profile extruding line. Particularly, FAYGOPLAST able supply PE, PPR pipes at speeds that can reach up to 40m/s.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy