While purchasing a blow moulding machine, the most elemental thing for you should be how to calculate its real cost. This expense is not only about the currency that you will pay in order to have the machine but it goes beyond of this. There are other costs related to it like how much your cost of running the machine would be and maintaining it as well costing you on repairs if there is any mishap.

However, the actual cost of a blow moulding machine can wildly vary according to some main points. Things like the size of the machine (how many shapes it can make at once, which we call cavities), how fast it is able to produce outcomes in a given time frame and so on all directly effect its final cost as well. In this regard, the choice of machine which meets your production objectives and is also affordable is very important. This means that you can be sure of being making a good investment when it comes to this matter.

Blow Moulding Machines'.These machines come at different prices, this makes the cost of blow moulding increased. from the type of machine you want to buy, and on the quality of materials used in manufacturing it, size matters at all as well which brand company this belongs. As a rule, brand new machines run a higher price than previously used ones. Remember that used machines can come with hidden costs, so caution is advised. These will require maintenance or repairs which adds to that cost.

Also, where the machine is manufactured. For instance, Chinese machines can possibly be purchased at a more attractive price compared to European or American alternatives. At the same time, price should be thought of as different than just how much money you have to spend — in other words if an espresso machine is high-priced or cheap but still a good value. It can also factor into long-term costs and even whether issues may present themselves with a so-called factory-refirb model down the road…assuming they are not covered by copious customer service/ support which would do well for customers like most warranties today….

Buying a blow moulding machine for sale is not that easy, you will have to wisely research before deciding.URL Learn about the three different types of machines that you can buy, what features each type offers and how much a good machine costs. In this post, you will be provided with the key information that all sewing machine buyers should know when they go into a purchase of a new one which tailor fits their production needs and money wallet as well.

You also must consider reviews of the machine, and even user reviews about buying product from that company in general. That way, you can ensure that they are reputable and able to deliver high end products as well as top tier customer service. Doing this kind of research will prevent you from purchasing a machine that could fail or become unsupported in the future, which can cost more money down the road.

The type of manufacturer you choose will also make a big difference––you want to find an established name that builds robust units and offers great customer service. Before you buy, do the detective work and find out if the manufacturer offers any type of warranty or guarantee. So, this can ease your concerns that you will be there if something does happen to go wrong.

FAYGO UNION GROUP now more than 500 customers spread across countries like UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. From Europe, America (Canada, Mexico, Brazil Venezuela, Chilly, etc.) and Saudi Arabia, Iran Syria, India, Thailand Indonesia Thailand Indonesia. Many customers coming from Africa as well as Asia. Our factory, which is located in Zhangjiagang City, has an area of 26650 square blow moulding machine price. only takes around two hours driving to SHANGHAI International Airport.

Service online: sale managers are available 24/7 give customers most quick answers. invite you to contact us have any blow moulding machine priceabout our products. Patents certificates: Faygo Plast has 13 national patents, including eight invention patents. keep improving our products and are able to provide the most recent technology our customers. product have CE and ISO certification.

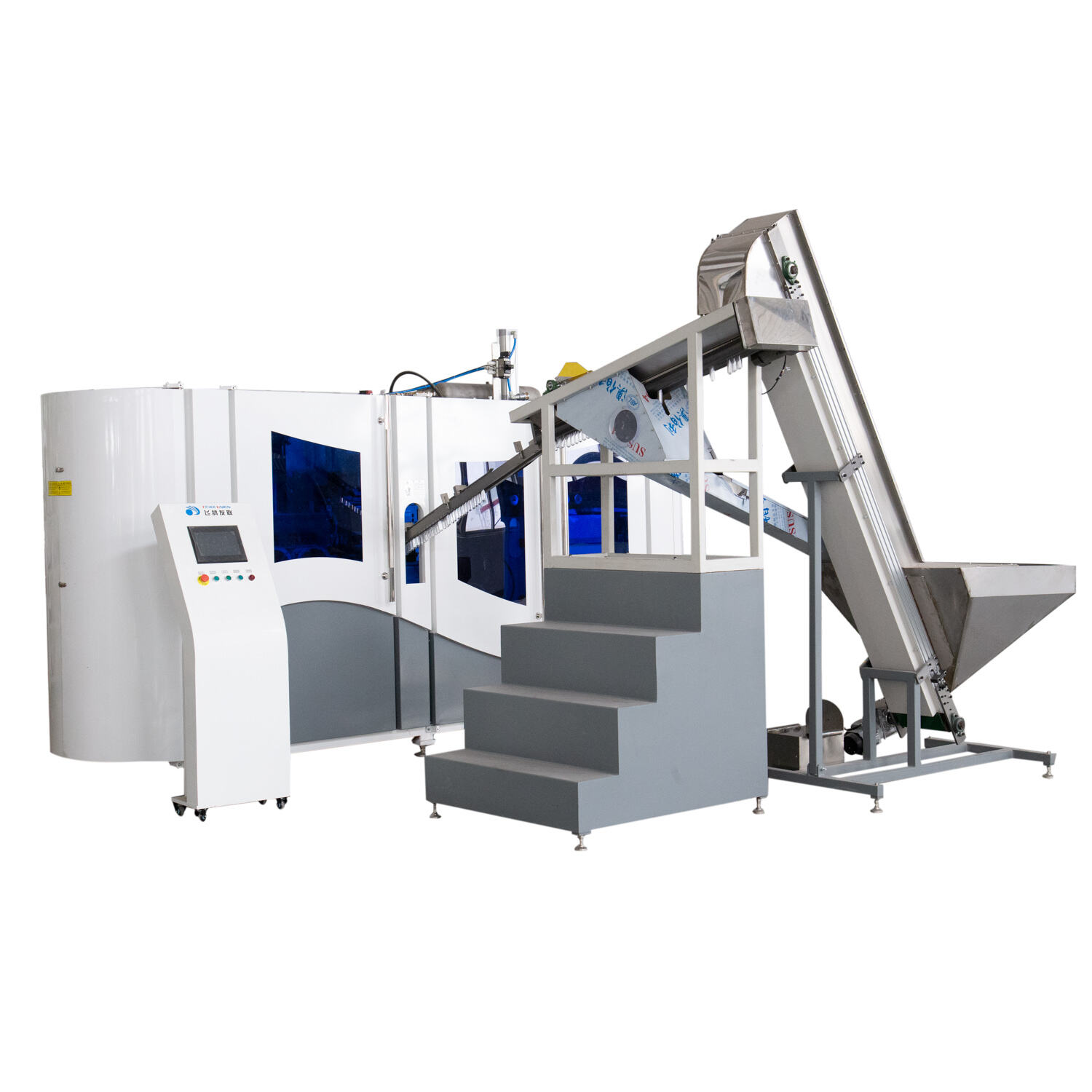

FAYGO UNION GROUP has 3 branch factories. One FAYGOBLOW that designs manufactures blow molding machine PET, PE etc. FAYGOBLOW has 5 patents invention, as well as 8 patents for utility models. FAYGO PET blow moulder is the fastest and most efficient design available the blow moulding machine price. second manufacturing facility is FAYGOPLAST, which make plastic extrusion machinery, including the plastic pipe extruding line and extruding line made of plastic profile. Particularly, FAYGOPLAST provides high speed up to 40 m/min PE, PPR pipe line.

More output (doubled) Rotary perform continuous running instead of stepping step-by-step run more smoothly. Reduce Bad Bottle Rate. Only two heating boxes, with each head's distance the heating source decreased to 38.1mm, which can reduce 30% more blow moulding machine pricethan the conventional model, which is about 130000kwh electric power, so an entire year, based on 8 hours per day, could reduce 20000USD only heating power. More than 100+ countries choose to be partners and my company after service team.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy policy