Blow Injection MoldingOne of the most interesting as well fast development in many product rising process! Amazing and it has been influencing us for many day to day products that we consume. You know those plastic bottles… the water, of course or soda ones? Though, if you have ever wondered how a piece of plastic is turned into one of your favourite germy killing gadgets then i think its safe to guess it was made in booth injection mold machine.

Simply put a blow injection moulding machine melts plastic down and then reshapes it in many different ways. It is given a lot of importance in manufacturing since it helps to production items fast and accurate. The barrel is sort of like the long, tube-like thing with a screw inside that turns and pushes molten plastic into a mold. They are the best resource that utilizes melted plastic and shapes it in its perfect form hence deliver a certain shape. The gadgets that we use currently are a marvel of this technology, and the products of companies like their Water TPR (Thermal Plastic Rubber) also implement 2K Injection Molding.

The utilization of blow injection moulding machines is a major industrial breakthrough when it comes to the manufacturing process in producing products. Earlier people were using machines which could produce only one product at a time so this procedure had been too slow plus not effective. Not only did this slow item production down to a crawl, When things are able to be produced in large quantity altogether not, with the help of blow injection moulding machines now! Now the entire production process is heavily sped up and streamlined. It is also used to crop packing able and marketable size/shape equal products.

Many of these millions of companies use blow injection moulding machines as part and parcel with their production lines. One of the biggest reasons behind this is their speed to produce products. Similar to machining on steroids, rapid manufacturing takes this concept and allows for parts to be produced so quickly that a product can go from design straight through delivery in no time at all. This is tremendously useful for companies attempting to outsmart buyers by one step ahead. This makes machine like this also perfect, and every piece that goes out of the maschine is going to be a good one. This also makes it much easier for companies to anticipate and send out their items without fretting about sizing.

Accurate Blow injection moulding machines The good news is that impact Injection Moulding Machines are precise and therefore, they can generating high quality items. The molten plastic is shaped using specialised moulds made of strong metal moults with designed shapes. The plastic is melted in the injection-moulding machine and then shot into the mould by high pressure, where it cools to form a rigid but pliable part that assumes themanifold of thermostatic runners. All the items from inside have standard size and shape since machine is highly precise. This standardization permits companies to package and distribute their goods with the confidence of what kind of batch uniformity they are going to receive when auctions hit warehouses.

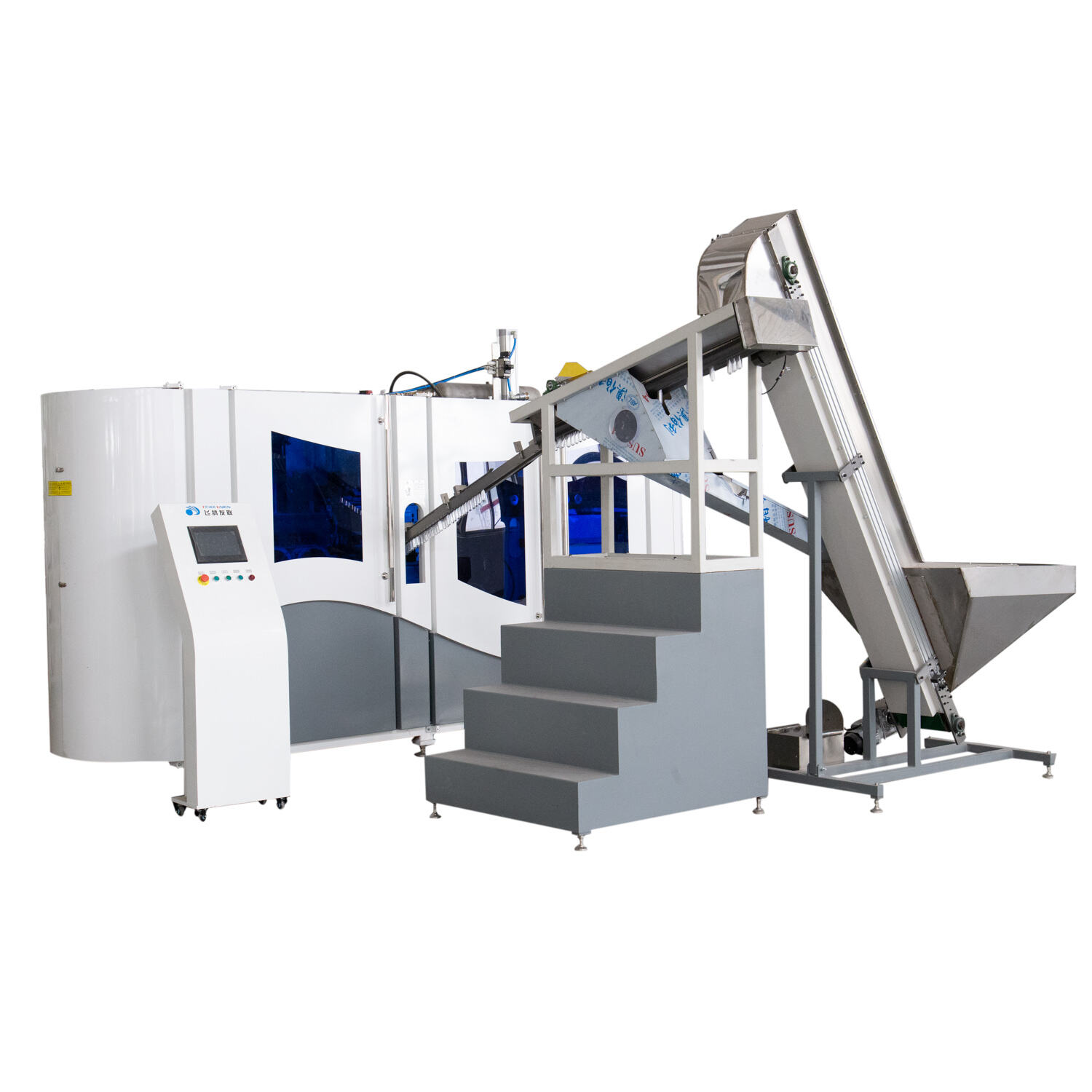

Moreover, you will discover that these latest blow injection molding machines are able to increase not just productivity but have a multitude of imbibe method functions as well so that they work even more efficiently. Machines often incorporate automated capabilities, meaning they are capable of functioning themselves with minimum human involvement. It makes things quicker and less error prone. Plus, you can instruct these machines to create same sort of goods that saves your time from shifting molds for others. In addition the plastic products being shaped can then be quickly cooled due to these devices enabling much faster production of items. Improved features now allow manufacturers to take advantage of the third or so overlap in their crews' available and run as-many-as-possible products within a specific time window.

output been increased (doubled) Rotary perform continuous running instead of step-by-step, and run more smoothly. Reduce Bad Bottle Rate. Only two heating boxes, with each one's heating head's distance reduced to 38.1mm which could reduce 30% more electricity than conventional one, about 130000kwh electrical power, which blow injection moulding machineone year based on 8 hours per day, can reduce 20000USD solely heating power. More than 100+ nations choose us as their partners as well as my own after-service team.

FAYGO UNION GROUP has 3 branch factories. One FAYGOBLOW that designs manufactures blow molding machine PET, PE etc. FAYGOBLOW has 5 patents invention, as well as 8 patents for utility models. FAYGO PET blow moulder is the fastest and most efficient design available the blow injection moulding machine. second manufacturing facility is FAYGOPLAST, which make plastic extrusion machinery, including the plastic pipe extruding line and extruding line made of plastic profile. Particularly, FAYGOPLAST provides high speed up to 40 m/min PE, PPR pipe line.

Sales managers online 24 hours day provide the most rapid service. you have any questions about products or services, please contact . Patents and Certificates: Faygo Plast has 13 national patents. Among them are 8 invention patents. constantly improve our products to blow injection moulding machinelatest technologies to our customers. Our products have CE ISO certifications

FAYGO UNION GROUP now has over 500 customers different countries, including UK, Spain Germany, Norway Switzerland Italy Turkey Russia etc. From Europe ,and America, Canada, Mexico, Brazil, Venezuela, Chilly etc from America, and Saudi Arabia, Iran, Syria, India, Thailand, Indonesia etc. A lot of our blow injection moulding machinecoming from Africa and Asia. Our factory, which located Zhangjiagang City, covers total area f26650 square metres. From airport, factory just two hours.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy