Fast machines are some of the coolest things on this planet. Are you familiar with automatic extrusion blow molding machines? These machines are awesome for creating all kinds of plastic containers, such as water bottles, shampoo features and even food grade containers! Here is more about the inner workings of these machines, and all they have to offer businesses as well those who use them in their day-to-day lives.

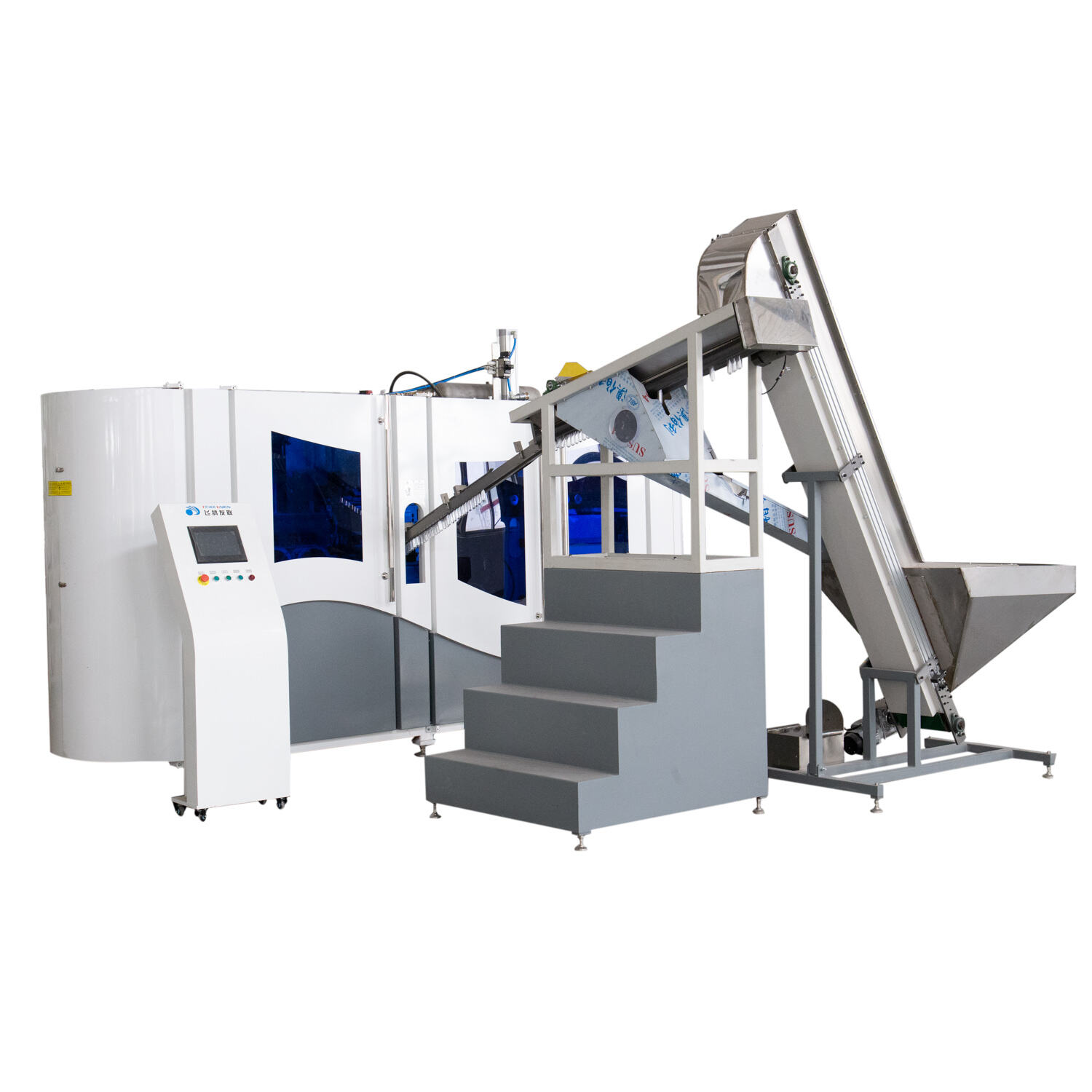

This is how it works; First the machine takes some tiny stuff called pellets which are ends of plastic. The machine heats up the plastic and turns it into a liquid. This is then forced through a long tube called an extruder as shown above. The melted plastic is directly ejected into an inflated long cylindrical tube known as a parison from the extruder. It is at last placed in a mold from which air pressure can be used to blow and give the container shape. This is a truly fascinating feature.

It is fully automatic so the machine does all the tasks itself. It is a great time-saver instead of creating containers completely manually, which require you to do each and every step. Since the machine is so quick, it jams these parts themselves as well, and if your business requires you to produce a high number of products in less time than other businesses do then this would be very beneficial for the business.

And automatic extrusion blow moulding machines offer this solution! They require single or two professionals to control them and result in saving workers money, resulting it low costing. Moreover, such machines are very fast - they can produce hundreds and thousands of containers in no time. This means companies can stop wasting their money and time by doing certain things on your behalf to get you the goods faster.

But after all, category by categories of industry their need is varies according to use like required plastic container for Food Packaging, Beverage and Bottling etc. Large containers do need to be dispensed also for juice or sauces with other business, yet are smaller such as creams or sauce. Other businesses may prefer a colored container for branding, while some companies want clear containers to show customers the sublanticregation inside. The good news is that the automatic extrusion blow moulding machines can adapt to all these conditions!

The mold that makes the containers, for example, can readily be switched to accommodate different shapes and sizes. A business is able to create their own exclusive container by changing the mold in this way. A machine that has color pellets in it can also use special colors by adding them to a similar, but separate have upon which the white or yellow plastic is added. This allows businesses to create container images precisely tailored for their unique requirements and ideas.

For example, The Control panel on the machine which allows the operator to know and change settings quickly. The control panel will be displaying relevant information, like the temperature of plastic and speed at which extruder is running. This provides the operator with useful feedback to see how anything is working so he can optimize his machine. If there are any issues, the operator is able to ensure that plant machinery remains operational.

Increased output(doubled) Rotary perform uploading Soft continuous, automatic extrusion blow moulding machinecontinuous running, instead of step-by-step and movement that \more gentle. Reduce Bad Bottle Rate. Only equipped with two heating boxes, each one's heating head's distance is reduced to 38.1mm and can save 30% electric than the conventional model, which \about 130000 kwh of electric power. So, for a year that is based \eight hours per day, can reduce 20000USD only on heating power; More than 100+ countries have us as partners my company after service team.

sales managers are available 24/7 to offer most efficient service. Please contact have any questions regarding our products. Patents certificate: Faygo Plast has 13 national patents. Among them are eight invention patents. constantly improve our products provide latest automatic extrusion blow moulding machine to our clients. products come with CE and ISO certifications

FAYGO UNION GROUP has 3 branches factories. FAYGOBLOW is blow molding machine producer PET, PE and other materials. FAYGOBLOW is owner of five patents invention, and 8 patents utility models. FAYGO PET blow molding machine one of most energy efficient fast-moving designs automatic extrusion blow moulding machinethe world. second plant is FAYGOPLAST which manufactures plastic extrusion machinery, including extruding lines made of plastic, extruding line for plastic profile. Especially FAYGOPLAST can supply high-speed lines up to 40 m/min PE, PPR pipe line.

FAYGO UNION GROUP now has over 500 customers different countries, including UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. Europe ,and America, Canada, Mexico, Brazil, Venezuela, Chilly etc from America as well as Saudi Arabia, Iran, Syria, India, Thailand, automatic extrusion blow moulding machineetc. from Asia a lot clients from Africa. Our factory situated Zhangjiagang city, which covers an area of 26,650 square metres. distance from airport to factory is just two hours.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy