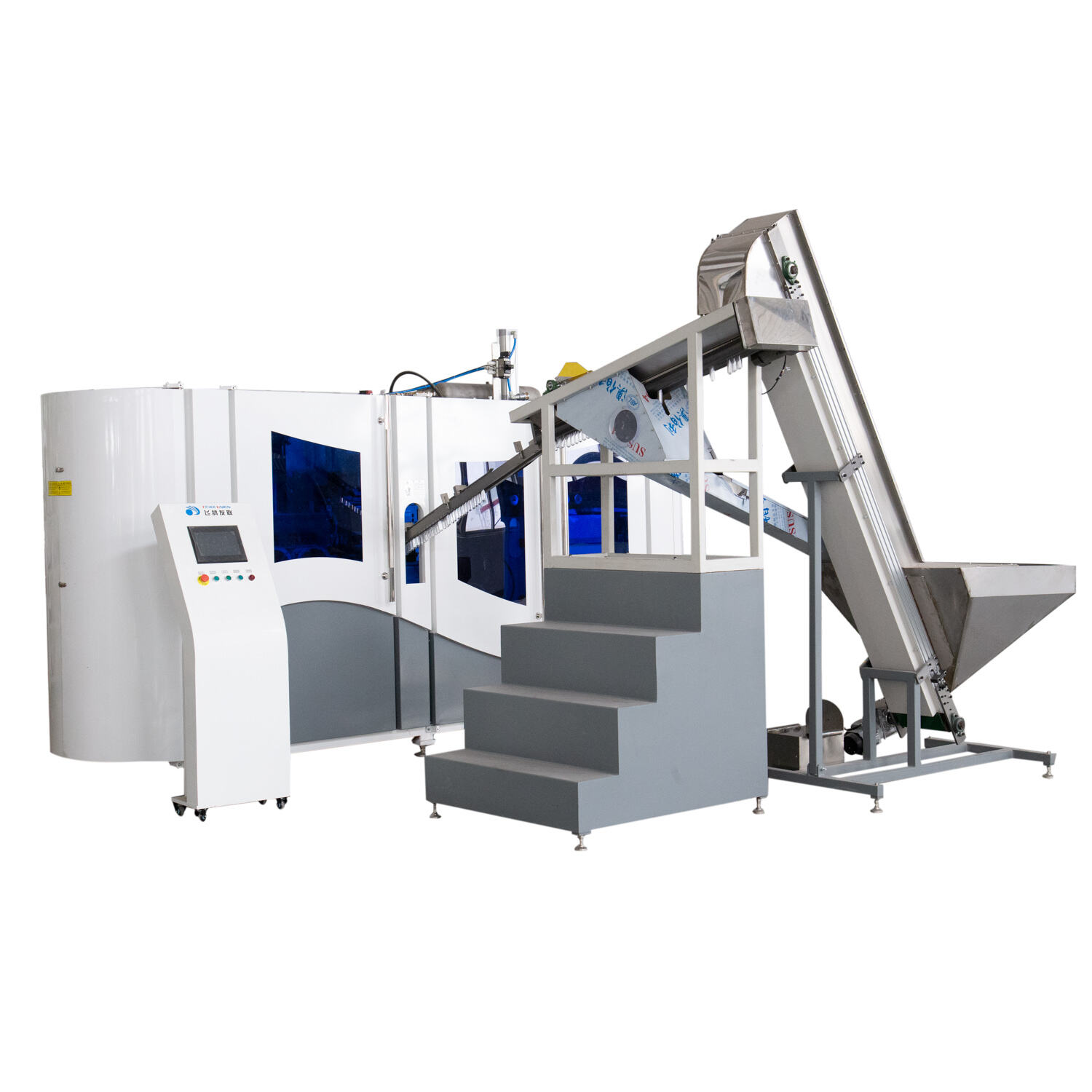

The manufacturers use automatic blow moulding machines in order to produce plastic bottles and containers. The process obviously required a time-consuming effort from us and this is what guarentees the overall quality to each single unit.

For manufacturers, blow moulding automation represents a massive cost cutting measure and time saver. This new way provides the fastest replication of same or similar products. Furthermore, the machine can process different materials to ensure that quality standards are always met across all discussed parts products. Manufacturers can depend on their products to be in accordance with all specified needs.

The transformation that is taking place in the manufacturing industry is a big heap because of Automaticblow molding machines They allow manufacturers to deliver quality goods more efficiently. These are The Articles that the power structures consensually manufactured, as if by natural law - no impostions or difficulties. A bottle blow molding machine is a kind of equipment that can produce thousands of products in just an hour, which can help reduce the production cost as well as increase the total output.

Blow molding is the process of melting plastic and forming it into a hollow container by blowing air. Automation has made this much easier and faster. For a complete automatic blow moulding machinery this is an excellent case, since it not just quickens the production process but rather likewise diminishes human intervention. Consequently, this automation offers higher productivity and lower production cost.

Automatic blow moulding machines are referred to as game-changer when it comes to enhancing the output and reducing manual work. Those machines work with high speeds and they produce any products the same making human labour not needed. This means that you can get more quantity of goods in less time and with fewer workers. At the same time, it is even able to detect every single defect in all products and filter out only the ones that satisfy a stronger standard of quality. In such a condition, manufacturers can opt for automatic blow moulding machine which is again of immense help and labor- saving time-spending money with also work.

In Short - One of the most advanced technology for blowing in Production auto blow molding machine which decreases human effort and make all things easier while performing blows. In addition, these machines offer a degree of production and at very low labor rates (they can be configured to run 24/7) which ultimately are the source of considerable savings on many different fronts pertaining still productivity. These robots are breaking away from traditional production methods, to handle tasks with much less effort and getting the job done more effectively. Perhaps less technically savvy younger readers may not understand all the little technical nuances, but they certainly come to realize just how important these machines are as a powerful aide in producing better and nutritious foods for society.

FAYGO UNION GROUP has 3 branch factories. FAYGOBLOW a blow molding machine manufacturer PET, PE other materials. FAYGOBLOW is owner of five patents related to inventions, eight patents for automatic blow moulding machinemodels. FAYGO PET blow moulder is quickest and most effective design the world. second plant is FAYGOPLAST, which make plastic extrusion equipment, which includes extruding lines for plastic pipe, plastic profile extruding line. Particularly FAYGOPLAST is able offer PPR and PE pipes speeds that can reach that can reach 40m/s.

increase output(doubled) Rotary perform uploading a soft continuous manner. perform continuous running instead of step-by-step with more smooth soft movement. Reduce number unsuitable bottles. Only two heating boxes, with each heating head distance automatic blow moulding machineto 38.1mm that can cut down 30% more electricity than conventional one, about 130000 kwh electric power. So, for year that is based eight hours per day, it could save 20000USD only on heating power; Over 100 nations choose as their partners also my company's after service team.

Presently, FAYGO UNION GROUP has more than 500 customers across different countries which include UK, Spain, Germany, Norway, Switzerland, Italy, Turkey Russia etc. From Europe America, Canada, Mexico, Brazil, Venezuela, Chilly, etc. from automatic blow moulding machineSaudi Arabia, Iran, Syria, India, Thailand, Indonesia etc. from Asia a lot of clients from Africa. factory located in Zhangjiagang city, which covers area 26,650 square metres. only two hours driving from SHANGHAI International Airport.

Service online: sales managers are available 24 hours day will provide our automatic blow moulding machine with the fastest reply. you require any further information regarding our products, please don't hesitate contact . Faygo Plast holds 13 national patents, including eight invention patents. keep improving our products and offer latest technologies to customers. products have CE and ISO certificates

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy Policy