Ever wondered how you create those intricate plastic bottles, jugs and containers? One approach to do this is by the process of blow molding. It is a method which uses air to give hot plastic its form, mainly there are two types stage and extrusion blow molding. Two cavity blow molding machine is also a special kind of blow molding machines are many factories use. As a newbie to this you must be thinking how does this machine work and where can I use it!

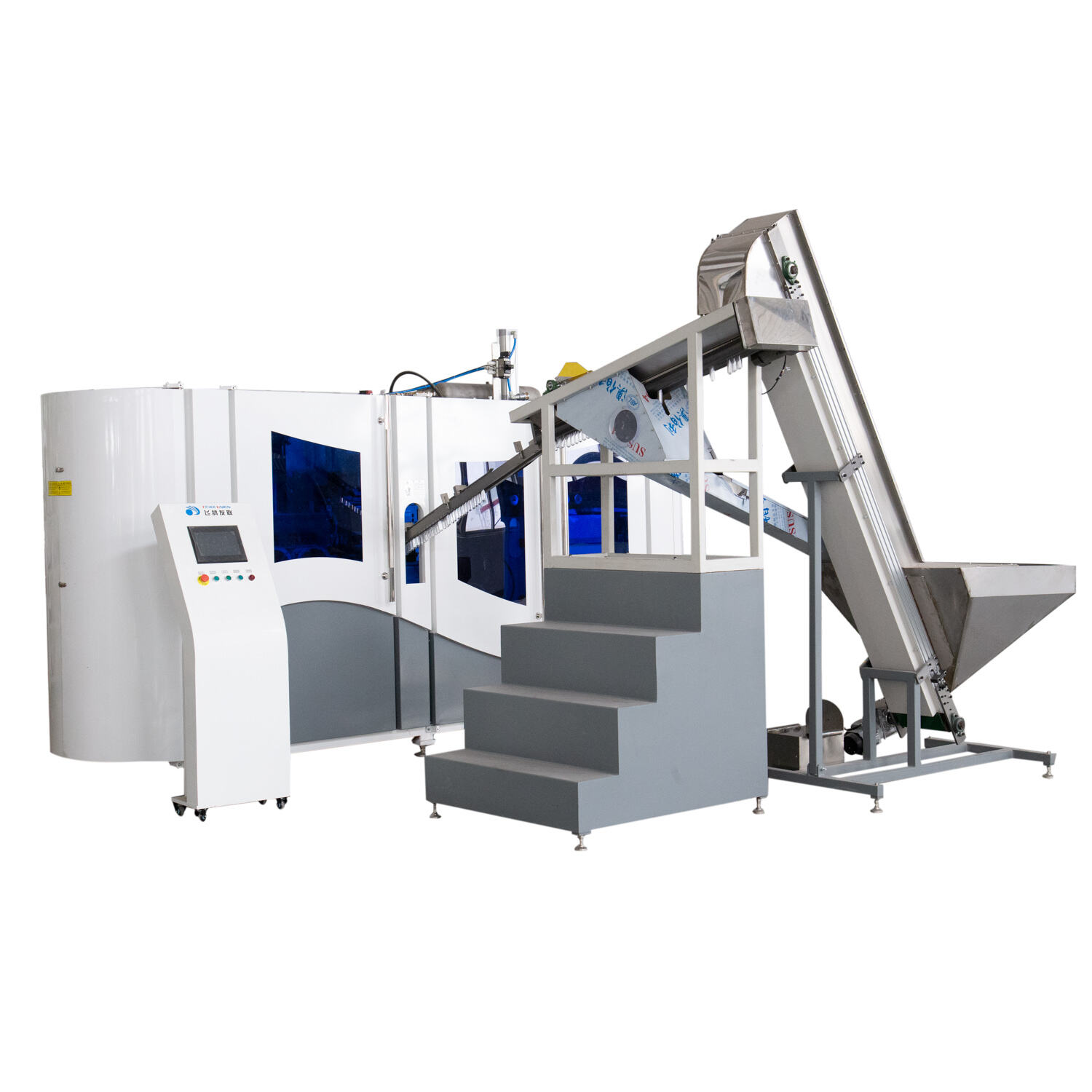

A two cavity blow molding machine is a wonderful kind of equipment that you can use to produce two different plastic items. Thus, one bottle is constructed on that side while another different one with a completely unrelated SKU item number it gets built simultaneously. In other words, since it produces two items at once and can produce additional plastic pieces double the time a machine forming single item. This is a very practical feature when it comes to factories that need mass produce plastic items quickly and efficiently.

For example a factory, which must produce 1000 plastic bottles one day. It will take so much time to make those 1000 bottles using a single-cavity machine. But in a two cavity machine they can make the same 2 bottles simultaneously. Which means, in just 1 day, they can prepare a combined total of 2000 bottles! This machine helps factories produce plastic goods at a faster rate, and also it meets all the growing needs of any plastic product from customers.

An additional important feature of the two cavity blow molding machine efficiency is its ability to save time and make more products. One of these reasons is the fact that it reduces wastage. Two examples of both a large-scale and small scale form of waste are: Large Scale - Automotive production, when materials went to assembly line without even being used Full-Scale Individual WasteIndividually measure the amount they throw awayWant everything on demandAlways buy things out off publicity Emit everydayTake actions that ARE aware yet simply too wasteful. It can also prevent one side of the machine from any mistake or problem on this hand, not stopping it to work. This means that if one of the cavities goes bad, then you can still use another functioning cavity to keep on churning out products or parts - reducing the number of items being tossed aside and decreasing wastage. And this is also environmentally merchandise for the factory itself!

Another advantage of a two cavity blow molding machine is that it allows factories to produce more products in equal execution time. This will allow the factory to make more money as they can sell a lot of products. They make money by selling the more products they sell. It also means that consumers have more plastic items to purchase and consume in the way humans do. An excellent illustrated product with an appealing and efficient factory process is a win-win for all parties involved!!

This also allows for factories to save money making a two cavity blow molding machine very useful. This way, not only do factories keep their production goals on time by manufacturing more plastic products in a shorter amount of time. This type of speed can reduce expenses in paying employees as they may need not to put on additional effort or work overtime just so that their goals will be meetjuice. In addition, the two cavity machine could allow plants to need fewer machines in order to meet production demands; this can result savings.

FAYGO UNION GROUP now has over 500 customers different countries, including UK, Spain Germany, Norway Switzerland Italy Turkey Russia more. Europe ,and America, Canada, Mexico, Brazil, Venezuela, Chilly etc from America as well as Saudi Arabia, Iran, Syria, India, Thailand, 2 cavity blow moulding machineetc. from Asia a lot clients from Africa. Our factory situated Zhangjiagang city, which covers an area of 26,650 square metres. distance from airport to factory is just two hours.

sales managers are available 24/7 to offer most efficient service. Please contact have any questions regarding our products. Patents certificate: Faygo Plast has 13 national patents. Among them are eight invention patents. constantly improve our products provide latest 2 cavity blow moulding machine to our clients. products come with CE and ISO certifications

FAYGO UNION GROUP made up of 3 branches. FAYGOBLOW is blow molding machine producer for PET, PE other materials. FAYGOBLOW is owner of five patents invention and 8 patents utility models. FAYGO PET blow molder is fastest most effective 2 cavity blow moulding machineits kind in the world. second manufacturing facility is FAYGOPLAST. makes plastic extrusion machines for example, extruding lines made of plastic pipe, and extruding plastic profiles. Particularly, FAYGOPLAST can offer PPR and PE pipes at speeds up to 40m/s.

increase output(doubled) Rotary perform uploading a soft and continuous manner. perform continuous running instead step by step and movement is more gentle. Reduce number faulty bottles. fitted with two heating box, each heating head distance minimized 38.1mm, which can reduce 30% more electricity than the 2 cavity blow moulding machinemodel, which is about 130000kwh electrical power, which means one year based on 8 hours a day, you could save you 20000USD only on heating power; Over 100 countries choose to be partners as well as my own after-service team.

Copyright © JiangSu Faygo Union Machinery Co.,Ltd All Rights Reserved. Privacy policy